How is the Film Hardness Measured?

The notch hardness of the coating film can be determined according to the method in the national standard "Scratch Test of Varnish and Color Paint" (GB/T927S-98. GB6554-8). This method is used to measure the hardness of the coating (durrometer)

(1) Equipment

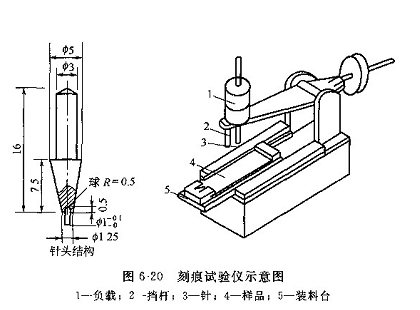

① Notch Hardness Tester The structure principle of the instrument is shown in the figure, mainly composed of a notch needle and a sliding plate. The head of the needle is equipped with a steel ball with a diameter of 1mn. The load can be applied to the needle, and the slide plate can be moved (motorized or manually). It is used to fix the sample.

②10 times magnifying glass.

2) Sample The preparation method of the sample is not described here.

(3) Test procedure The sample should be treated for 24 hours under the condition of 23℃±2℃ and relative humidity of 50%.±5%. and measured under these conditions.

① Apply the specified load Take a used needle and check it under a magnifying glass. The needle head should be smooth and hemispherical without dirt.

Fix the needle on the instrument so that its axis is perpendicular to the coating when in the working position. Centrally tighten the sample on the slide plate, and turn on the power supply of the electric indicator.

Apply the specified load to the needle, and gently place it on the sample, so that the slide plate moves evenly, the length of the notch shall not be less than 60mm, and observe whether the layer is pierced through the electric fD indicator or a magnifying glass.

Each needle is only for one test.

② Determine the minimum piercing load according to the procedure in ①. The initial applied load should be smaller than the load value expected to cause the coating to puncture, and increase gradually with an appropriate load (such as 0.5N) until the coating is punctured, and the sample is tested with the minimum puncture load value. Repeat test verification.

(4) Results Report whether the coating is pierced under the specified load value, and the minimum load value for piercing the coating.

- 1What is scratch hardness?

- 2What is scratch hardness?

- 3Determination method of paint film hardness - swing rod hardness, scratch hardness, indentation hardness

- 4How to use the Dutch TQC coating hardness test pen SP0010

- 54 test types to test coating strength

- 6Types of scratch hardness and working methods of pencil Hardness Tester

- 7Application of Pendula Hardness Tester in determination of automobile coating Hardness

- 8Hardness test method of surface coating

- 9Pencil Hardness Testing of Modified Graphite Nanosheet Coating