Resist coating method

Resist Coating Method:

A key requirement to ensure repeatable, reliable and acceptable results with photolithography is to have a uniform photoresist coating on the substrate surface. Photoresist is usually dispersed in a solvent or aqueous solution and is a high viscosity material. Depending on the process requirements, there are many options for applying photoresist:

spin coating

spraying

Dip coating

inkjet printing

Slot Die Coating

spin coating

Spin coating is a common method for coating substrates with photoresist. This is a method with high-throughput and homogeneity potential. Spin coating works by dispensing typically a few milliliters of photoresist onto a substrate spinning at several 1000 rpm (typically 4000 rpm). Resist can be dispensed while the substrate is stationary and then accelerated to a certain speed (static spin coating), or it can be dispensed while the wafer is already spinning (dynamic spin coating). During spinning, any excess resist is spun away from the edge of the substrate.

The centrifugal force experienced by the resist on the wafer surface causes the viscous resist to spread out into a uniform film. The height of this film is directly controlled by the rotation speed of the substrate, allowing the operator to achieve the desired film thickness.

In addition to spin speed, spin time can also be used to control film thickness. This is due to further thinning of the resist due to evaporation of some of the solvent or aqueous liquid used to disperse the resist. The loss of solvent also leads to the stability of the film so it does not collapse during subsequent substrate processing.

The main advantage of spin coating is that the coating step is very short, typically 10-20 seconds, which, when combined with dispensing and handling time, can result in a handling time of less than 1 minute. Another advantage is that the films obtained are very smooth and the thickness can be controlled reproducibly with great accuracy.

Disadvantages and limitations of spin coating occur when using non-circular substrates or thick (very sticky) resists. In these cases, air turbulence at the edges, especially at the corners, can cause accelerated drying of the resist. This over-drying then inhibits the release of resist from these areas, causing resist beads to accumulate around the substrate perimeter; this formation of resist sidewalls is known as edge beads. In the more sophisticated spin-coating systems, techniques have been developed to remove this edge bead through the precise application of solvents, or to limit its growth by controlling air turbulence.

Another limitation that may affect spin coating is that if the substrate surface has a large number of features or varying topography, the uniformity of film thickness may be affected. As the resist builds up in the holes or spaces, it results in thicker films and thinner films on the edges of features. This can be overcome with a two-stage spin curve or by using one of the alternative coating techniques.

spraying

Spray coating is an alternative to spin coating, especially when the substrate surface or morphology means that the photoresist cannot be coated with the desired uniformity. The basic principle of spraying is that photoresist is deposited to form photoresist, and photoresist is atomized into micron-sized droplets.

Droplets can be formed by a variety of techniques; the simple method is to generate an atomized spray from a nozzle similar to a conventional Spray Gun and nitrogen nozzle. Nitrogen is preferred because it helps reduce moisture or particulate contamination of the resist and produces a dry mist of droplets.

The second standard method of producing an atomized spray is to use an ultrasonic nebulizer. The ultrasonic nebulizer produces resist droplets through high-frequency mechanical vibration of the resist medium, and then transports them to the substrate through the carrier gas.

Droplets of resist are then deposited on the substrate surface, where they form a continuous film of photoresist. Thus, spray coating is able to cover the entire surface of a substrate, even of arbitrary shape, and provide a conformal coating regardless of topology. Additionally, less photoresist is wasted and yields are higher compared to spin coating.

In order to be able to spray photoresist, the resist needs to have a suitably low viscosity. Usually this is a few cSt and the resist may need to be diluted with a solvent. Dilution of the resist can lead to an acceleration of the resist aging process and the formation of particles within the media. Another limitation of spray coating is that it is difficult to form thin films <1 µm due to the random distribution of droplets landing on the surface. To form a continuous film, a minimum critical resist droplet density needs to be reached, which increases the minimum film thickness and increases processing time.

Dip coating

If the size and type of substrate are not suitable for spin coating, and photoresist is costly to the overall process, dip coating can be used as a solution for resist coating, even though the resist is less effective than spray coating. Consumption needs to be further reduced.

The process of dip coating is to dip the wafer vertically into the resist test tube and lift it slowly. A resist film then forms on the surface and thins as the substrate is removed from the photoresist bath. The thickness of the resist is controlled by the residence time in the solvent-saturated atmosphere, which controls the rate at which the solvent evaporates. The higher the removal rate from the resist bath, the thicker the photoresist film.

Thanks to this process, if both sides of the substrate need to be coated, the resist yield can reach 100%, which is a great improvement in resist yield compared to spin coating and spray coating. If the resist expires before it is consumed, the tank may need to be replaced, which will reduce yield, but still provide the most cost-effective of the three coating methods covered.

The photoresist usually needs to be diluted significantly, which can significantly increase the aging of the photoresist film and the frequency with which the bath needs to be replaced. Additionally, substrates with large variations in surface topography are not suitable as the resist will flow through the substrate and significantly reduce surface uniformity.

inkjet printing

Another method for dispensing resist is inkjet printing. This is similar to spraying, producing droplets of photoresist. However, unlike spraying, these droplets are produced in a stream rather than a mist. This droplet flow can then be precisely controlled and patterned onto the substrate.

Inkjet printing differs from other coating methods in that while it can be used to produce thin, uniform films of photoresist, its real advantage lies in using it to create patterns directly on the substrate. This can lead to significant savings in the amount of resist used by only depositing it where it is needed, reducing the cost and environmental impact of the photolithography process. In addition, some materials, such as organic semiconductors and conductive inks, can be deposited directly onto surfaces without a photolithographic process.

The downside of the increased flexibility and versatility of inkjet printing is increased coating time, resulting in lower yields of coated wafers and substrates. However, this can be counteracted by using multiple print heads and path optimization. Additionally, inkjet printing is not an ideal solution for coating thicker resists, as layers are typically only a few microns thick.

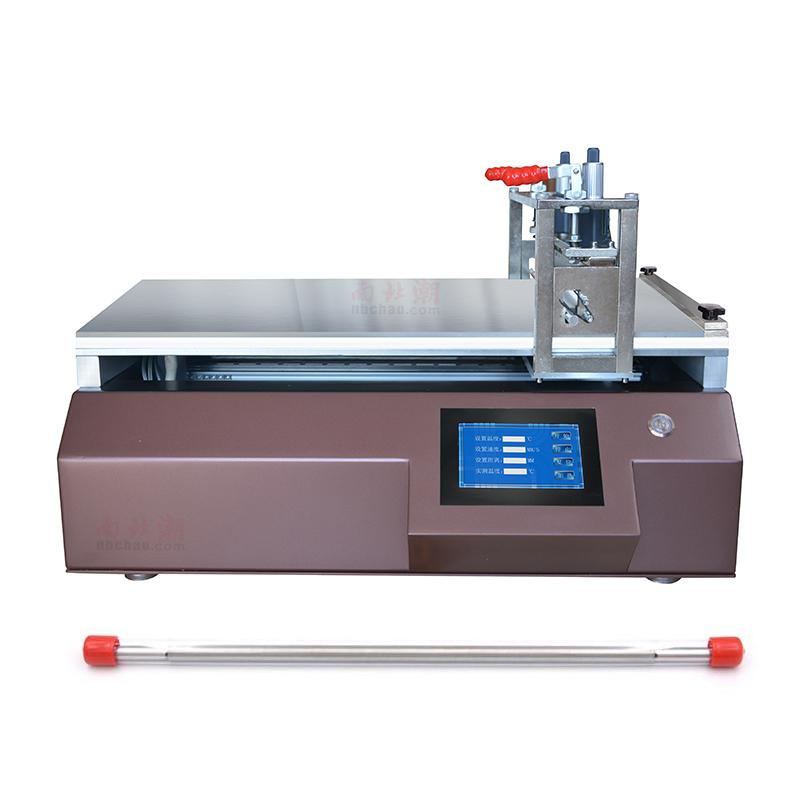

Slot Die Coating

Slot die coating. Slot die coating is a scalable manufacturing technique used in a range of industrial processes to produce uniform films and coatings. The principle of slot die coating is shown in the figure above. The printhead continuously dispenses photoresist onto the moving surface of the substrate, resulting in a uniform photoresist film. As the solvent in the wet photoresist evaporates, the photoresist film dries, leaving a uniform film that can then be further processed.

Slot die coating is a pre-metered coating technique; this means that all material dispensed from the print head of the coater is used to coat the surface of the substrate. This enables very low (or even no) levels of photoresist waste, which is a great advantage if photoresist represents a large material cost. Additional advantages of slot coating are that it is an easily scalable technique that can greatly increase the number of substrates. Slot die coating is also well suited for coating flexible substrates and for roll-to-roll manufacturing processes. In addition to photoresist coatings, slot die coatings (e.g. inkjet printing) can be used to coat any functional material that can be dispersed into a printable ink.

- 1Overview of resistant coatings

- 2Characteristics and construction points of corrosion resistant Coatings

- 3Application of corrosion resistant coatings on reinforced concrete surfaces

- 4Technological development and application of heavy anticorrosive coatings

- 5Application and performance analysis of silicon diffusion coatings

- 6Research and application of chromium diffusion coatings

- 7High temperature oxidation and corrosion resistance performance and application of aluminum diffusion coatings

- 8Zinc diffusion coating performance process and application

- 9Chromate coating technology and its application