What you need to know about Industrial Oven options and daily care

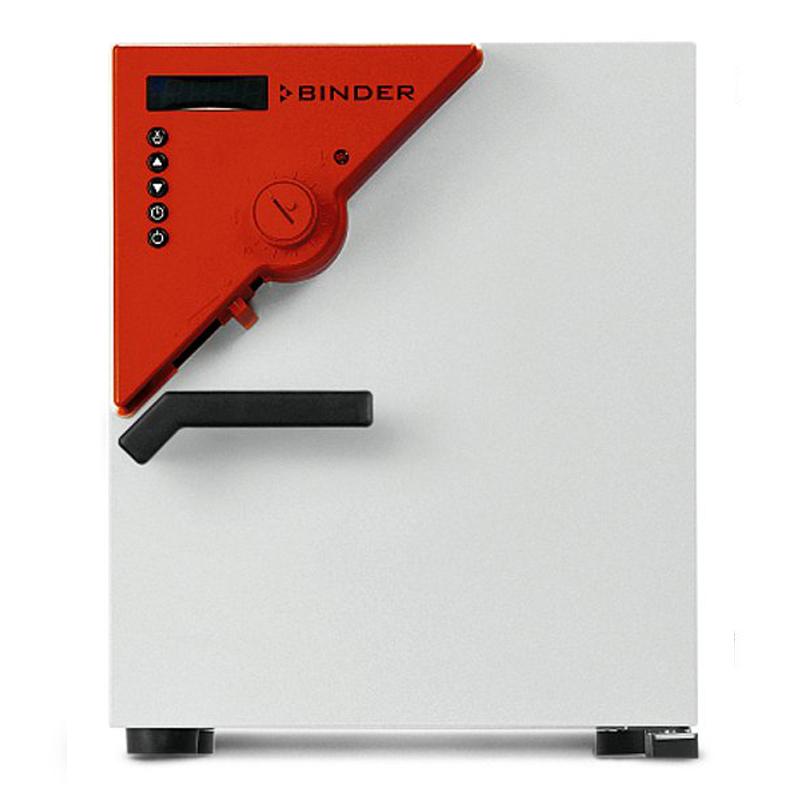

Shop for Industrial Ovens Items

1. Customization

Production capacity determines whether the size and specification can meet the production needs, and the production capacity is high. You can choose a crawler oven for industrial use from a reliable Test Chamber manufacturer.

2. Temperature

It is okay to choose a temperature 10 degrees higher than the actual use temperature. According to the process requirements, it is necessary to calculate the actual temperature difference required to ensure the baking effect. For example, if the working temperature is 150 degrees, 220 degrees, 360 degrees, the maximum design temperature is 500 degrees. Different products have slightly larger temperature differences when used at low temperatures. The actual use effect of 150 degrees and 220 degrees is not as good as that of a low-temperature oven. Using a 500-degree medium-temperature oven, the temperature difference of 150-degree baking is 2-5 degrees higher than that of a 250-degree low-temperature oven. Industrial ovens are divided into low temperature (0-250 degrees), medium temperature 250-600 degrees) and high temperature (600-1500 degrees).

3. Unwind

Multi-layer Industrial Oven. After the tray is configured, there are network disks, physical disks, punched disks, etc. If you have more, you can use a material shelf or frame.

4. Place the site

If the electrical oven environmental testing equipment is placed on the floor, you need to consider whether you can enter the door and enter the elevator.

Industrial ovens need maintenance after a long period of use. According to the time difference, it can be divided into daily maintenance, monthly maintenance and semi-annual maintenance.

Specific maintenance methods for Industrial Ovens

1. Daily maintenance of Industrial Ovens: clean the dust inside and outside the cavity, and keep the machine clean and hygienic. Check that the current from the ammeter is the same as the normal current. If there is any abnormality, please tell the maintenance personnel to repair it. If there is a sudden power failure, the heating switch should be turned off to avoid active activation when power is applied. Check that the fans are working properly and making any unusual noises. If there is any abnormal sound, please turn off the machine immediately and tell the maintenance personnel to repair it.

2. Monthly maintenance of Industrial Ovens: check whether the vents are blocked and discharge dust. Are the fans working properly? Maintenance personnel check whether the current is normal. Check whether the thermostat is accurate, if not, please adjust the static compensation or sensor calibration value of the thermostat. Check whether the heating tube is damaged and whether the circuit is aging. Check that the delayer is accurate and error-free.

3. Maintenance of Industrial Ovens for half a year: check whether the wiring and switches are normal. Oil the motor gearbox. The insulation of the transformer is not less than 5 megohms. If it is not reachable, the transformer will need to be updated from scratch. Clean the reflector with a soft cloth soaked in alcohol. Check whether the drive shaft and sprocket are loose, and whether the two sprockets are vertical. And check whether the tightness of the mesh belt is appropriate?

- 1What do we need to know about aging ovens?

- 2Selection of Industrial Ovens and daily care methods

- 3Use of laboratory ovens

-

TQC AB8000 GRADIENT oven$ 105179.00