Pressure sensitive adhesive type

There are many types of pressure-sensitive adhesives, which can be classified from different angles.

(1) Classification according to the main components of pressure-sensitive adhesives

①Elastomer-type pressure-sensitive adhesive The elastomer used in this type of pressure-sensitive adhesive was originally natural rubber and then gradually expanded to various synthetic rubber and thermoplastic elastomers. According to the elasticity used, this type of pressure-sensitive adhesive can be further divided into natural rubber pressure-sensitive adhesive, synthetic rubber pressure-sensitive thermoplastic elastomer pressure-sensitive adhesive.

a. Natural rubber pressure-sensitive adhesive This is an earlier developed, rubber-like pressure-sensitive adhesive. They are mainly based on an elastomer, which is still a large output of natural rubber, and are combined with a complex mixture of additives such as tackifying resins, softeners, anti-aging agents, pigments and fillers, and crosslinking (vulcanization) agents. High cohesive strength and elasticity, and it can be well miscible with many tackifying resins and resins to obtain a high degree of viscosity and good wettability to the adhered material, so natural thread adhesive is a relatively satisfactory type of pressure-sensitive adhesive. Material. Its main disadvantage is that there are unsaturated double bonds in the molecule, and the aging performance of light and oxygen is poor. However, its weather resistance and heat resistance can be improved through measures such as crosslinking and the use of anti-aging agents. Almost all types of pressure-sensitive adhesive products can be made with natural rubber pressure-sensitive adhesives.

b. Synthetic rubber and regenerated rubber pressure-sensitive adhesives are mainly synthetic rubbers such as styrene-butadiene rubber, polyisoprene rubber , polyisobutylene and butyl rubber, neoprene rubber, and nitrile rubber , together with tackifying resin and softener Pressure-sensitive adhesives made of additives such as anti-aging agents and anti-aging agents have their own characteristics. But none of them are as important as natural rubber pressure sensitive adhesives. Reclaimed rubber, especially pressure-sensitive adhesives made of recycled natural rubber, also has good performance and relatively low prices, so it is also valued.

c. Thermoplastic elastomer pressure-sensitive adhesives thermoplastic elastomers represented by styrene-butadiene-ethylene block copolymer ( sBs) and styrene-isoprene-styrene block copolymer (SIS) It is the main raw material for making hot-melt pressure-sensitive adhesives. Hot-melt pressure-sensitive adhesives do not use solvents, do not produce environmental pollution, and have high production efficiency. In today's society where the calls for energy saving and environmental pollution are increasing, the importance of such pressure-sensitive adhesives is also increasing.

② Resin-type pressure-sensitive adhesives. The resins used in this type of pressure-sensitive adhesives include polyacrylic acid, polyurethane , polyvinyl chloride, and polyvinyl ether. Among them, polypropylene vinyl acetate is currently used more , and its output has exceeded that of natural rubber pressure-sensitive adhesives.

a. Acrylate pressure-sensitive adhesives Acrylate copolymers obtained by copolymerizing various acrylate monomers are an important type of resin-type pressure-sensitive adhesives. Compared with the above-mentioned rubber-type pressure-sensitive adhesives, they have excellent, colorless and transparent appearance and good weather resistance; generally, good adhesion can be obtained without the use of additives such as tackifying resins, softeners and anti-aging agents. Pressure-sensitive adhesive properties, so the formula is simple; the use of copolymerization and cross-linking can make pressure-sensitive adhesives that meet various performance requirements. Therefore, in the past 20 years, this type of pressure-sensitive adhesive has developed very rapidly, and has occupied the position of natural rubber pressure-sensitive adhesive.

b. Silicone and other resin-type pressure-sensitive adhesives are pressure-sensitive adhesives composed of silicone resin and silicone rubber, which have excellent high temperature resistance and aging resistance. They are a relatively important type of special pressure-sensitive adhesives. The purpose is to manufacture various high-grade pressure-sensitive adhesive products.

Polyvinyl ether is a kind of resin pressure-sensitive adhesive developed earlier, but its importance has been gradually replaced by acrylic pressure-sensitive adhesive. In addition, resins such as ethylene-vinyl acetate copolymer (EVA), polyurethane, polyvinyl chloride, and polyvinyl chloride can also be formulated into various pressure-sensitive adhesives.

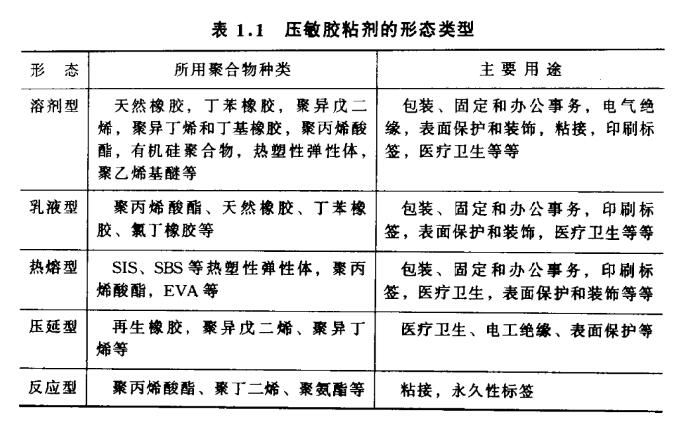

(2) Classification according to the form of pressure-sensitive adhesive

Pressure-sensitive adhesives can be divided into five types: solvent-based pressure-sensitive adhesives, aqueous solution-based pressure-sensitive adhesives, emulsion-type pressure-sensitive adhesives, hot-melt pressure-sensitive adhesives, and calendered pressure-sensitive adhesives, as shown in Table 1.l.

At present, emulsion-type, solvent-type and hot-melt pressure-sensitive adhesives dominate.

(3) According to whether the main polymer of the pressure-sensitive adhesive is cross-linked

Pressure-sensitive adhesives can be divided into cross-linked and non-cross-linked pressure-sensitive adhesives. Cross-linked pressure-sensitive adhesives can be divided into heating cross-linking type, room temperature cross-linking type, and photo-crosslinking type according to their cross-linking methods. Cross-linked pressure-sensitive adhesive has good bonding strength, especially suitable for making permanent pressure-sensitive labels.

- 1Application and Experimental Study of Film Coating Adhesive Technology

- 2High-low temperature resistance test solution for pressure sensitive tape

- 3Application of Film Applicator in Pressure sensitive adhesive film

- 4Composition material of pressure sensitive tape

- 5Pressure sensitive adhesive performance test overview

- 6Pressure sensitive adhesive tape

- 7Pressure sensitive adhesive Spreader