What happens to the material during tensile testing?

Tensile stress is the amount of direct loading associated with tension, or tensile force, that causes the material to stretch along the axis to which the load is applied. Tensile testing is performed to check the efficacy and behavior of materials when stretched. These tests determine the material's maximum strength, or load-bearing capacity, under optimal conditions of .

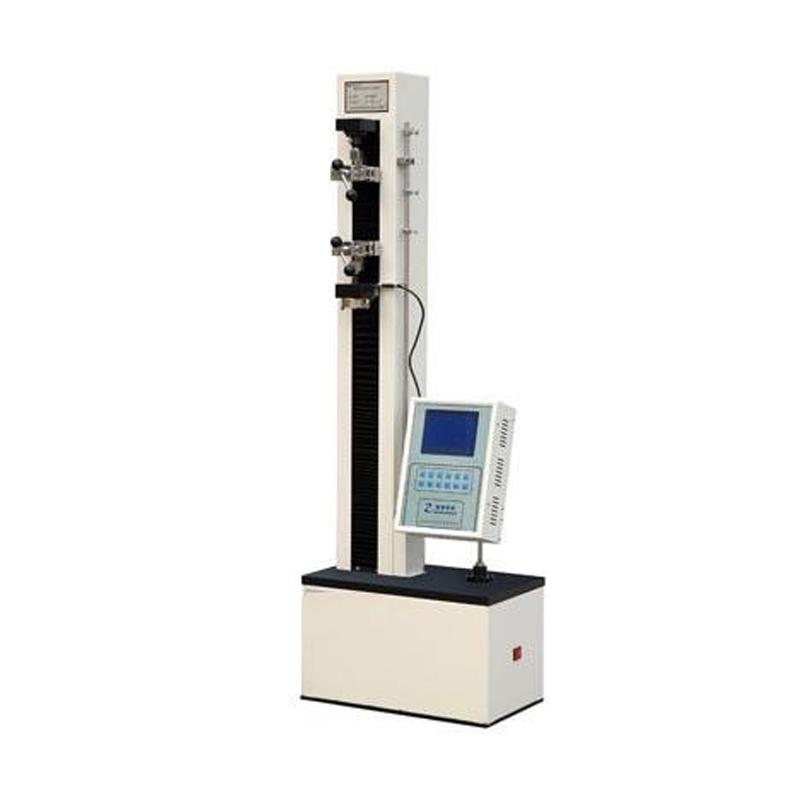

You can easily measure the tensile strength of a material with the help of a Tensile Strength Tester. Tensile strength Testers are highly versatile and can be used to check the breaking strength of packaging-related raw materials and finished products.

What is the main purpose of performing a tensile test on a material?

Tensile testing or tensile testing of materials is considered as one of the basic quality tests . When tension is applied to the material, it breaks, allowing manufacturers to conduct precise and accurate studies of its mass. Therefore, most manufacturers use this tensile testing machine in quality control laboratories and mainstream production chains to analyze the quality of materials.

The main goal of a Tensile Strength Tester is to check the tensile properties of a material. Thus, you will be able to perform material quality analysis and determine if your product is safe to use. You will be able to test the tensile strength of materials in various capacities with its large test range and improved peak load indication for accurate readings.

Tensile Strength Tester Complies with ASTM D429-73, ASTM D624, ATM D638-01 and ASTM

D76, IS 13360-5-7 and IS 3400 test standards. Most manufacturers consider a Tensile Strength Tester because of its versatility. Whenever you perform a pull test with a Tensile Strength Tester, you need to take some precautions to get the best quality results.

Before performing

Once you have your sample accurately placed on the Tensile Strength Tester, you can place it accurately on the machine. You can easily prepare a dumbbell-shaped test specimen or a rectangular test specimen for the Tensile Strength Tester. Tensile strength Testers can be used to test the tensile strength of materials in various sectors of different industries, including injection molding, automotive, blow molding and other related industries.