How to control the automatic feeding of the small coating machine? Video tutorial version

Small-scale coating machines for experiments are commonly seen in the market as semi-automatic coating machines. The coating machine only provides a coating platform and automatic control of scraping coating, but the experimenter still needs to manually feed the material when loading, which is harmful to the environment. The operator’s feeding amount and feeding speed have certain technical requirements, especially for samples that are volatile and easy to dry. The kind that scratches the whole paper.

In response to these problems of users, the NBCHAO small-scale coating machine has been further upgraded, and the automatic feeding system is used to automatically control the feeding speed and feeding amount, so as to realize automatic coating, improve the coating effect and coating efficiency, and also reduce the amount of samples. waste.

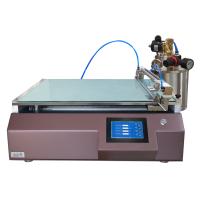

So how is the fully automatic intelligent small coating machine operated and controlled? Let's follow the editor to look down, first look at the operation panel,

The operation panel diagram of the automatic small coating machine above shows that not only the glue sizing time can be set, but also the vacuum adsorption control is also automated, and the vacuum adsorption and vacuum release can be adjusted freely. And the problem of the trough can also be heated.

The automatic small film coating machine is the same as other coating machines. After fixing the substrate, first set the heating parameters, speed, stroke, and gluing time on the operation panel, and then click start to start the automatic gluing. Check out the detailed operation video below

Do you still want to manually feed and coat after reading? If you have other questions about the automatic feeding film coating machine, you can communicate with Beichao Technology at any time. The following are the specific technical parameters of the automatic feeding coating machine.

| Membrane Proofing- Membrane | |

| Domestic TBJ-X2-DJ3 vacuum adsorption wire rod heating integrated coating testing machine |

| Specification parameters: coating speed 2~200mm/s, coating width 600*800mm, coating speed digital display, different speeds, vacuum adsorption size 600*800mm (customizable), vacuum hole diameter Φ0.7mm, vacuum hole distance 10 *10mm, Vacuum Pump size 380*180*280mm, speed control infinitely variable speed, base plate material aluminum alloy, coating accuracy ±3μm, heating temperature range RT+~200℃, temperature uniformity ±3℃, automatic ink filling system with customizable functions, Feeding principle Air source pressure flows outward, feeding motion mode reciprocating linear motion, feeding back and forth moving speed 2-150mm/s, adjustable discharge volume (adjusted by adjusting air pressure and outlet running speed), shaft transmission mode synchronous belt , The gas source of the feeding system is 0.6Mpa, which can be connected to a φ8 air pipe (self-provided). The power voltage of the feeding system is 220V, 50Hz. The maximum pressure of the feeding barrel can withstand 8Mpa. The material of the feeding barrel is 304 stainless steel with a wall thickness of 4mm. The feeding barrel is equipped with a safety valve, Pressure Regulator, Pressure Gauge, Air Relief Valve, Optional Accessories Leak Tank, Substrate Fixtures, Micro Leveling Foot Sets, Glass Plates, Silicone Pads and Weights (for applications with uneven substrate thickness) , Film width control baffle, dimensions 1022*810*630mm, feeding barrel volume 1L | |

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body