What is a Drop Tester and what is it used for?

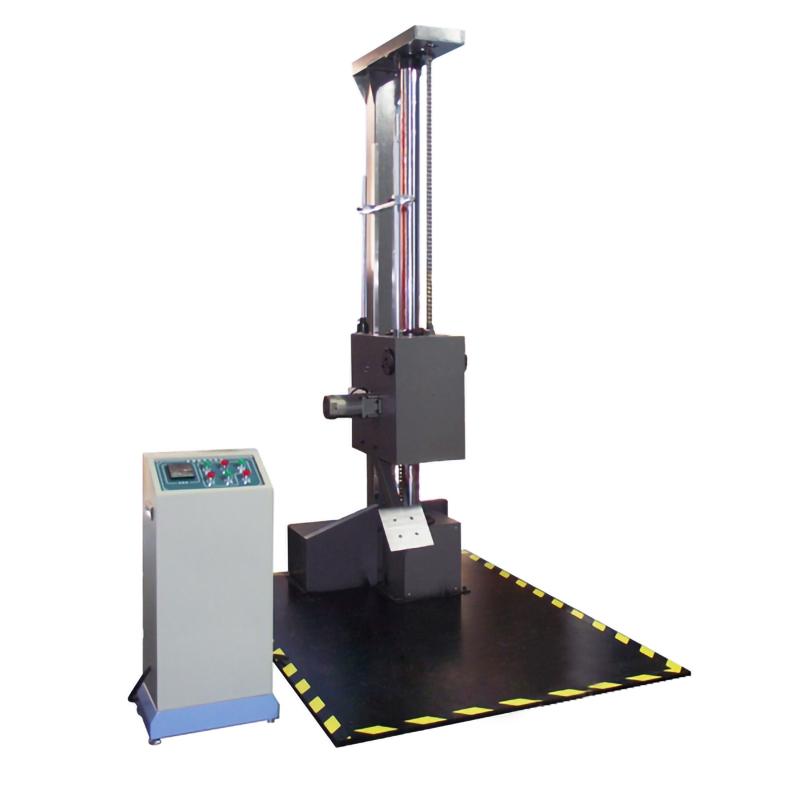

In the packaging industry, the importance of testing the strength of carton or corrugated boxes for checking quality cannot be overemphasized. Distributed loads will be threatened by drops or shocks. This decline will definitely affect the quality of the materials used to make it. So, with the help of Drop Tester electro-pneumatic model, you can easily evaluate the drop strength of corrugated boxes.

Introduction

The importance of testing the packaging of your goods cannot be overemphasized to ensure that nothing is damaged during transportation. If you deliver the product without testing, damage will result, or you may face loss due to rejection. Therefore, to ensure that your products should be tested before being delivered to customers, you should use a Drop Tester. One of our quality testing instruments is a Drop Tester, which will help you test the drop tolerance of your corrugated boxes or cartons.

From manual Drop Testers to electro-pneumatics, you can choose the right test model from Presto. You can easily drop test different materials to test the quality of the carton. With this lab testing equipment, you can easily test your packages against free fall, tumble and other types of handling while in transit and in transit. You can also

Learn how a Drop Tester can help test the durability of cartons.

By checking the drop performance of these cartons, you can make your products more efficient to use. When you can assess the quality of your products, you can rest easy and satisfy your customers with ease. Therefore, you can use this laboratory testing instrument to test the value of the packaging from various drop point angles.

The main purpose of using a Drop Tester

The main purpose of using this laboratory test equipment is to check the drop tolerance of the package. When these packages are dropped from a height, you can easily determine the effect . By testing the drop strength of your packaging materials, you can resolve any product damage issues and deliver high-quality products to your customers. You can also learn how a Drop Tester can help visualize the effects of free fall on your packaging.

-

CHINA BLD-613D Single Wing Drop Machine$ 1830.00

-

-

-

-

-

-

-