8 corrosion tests

Corrosion testing is one of the important duties of a corrosion engineer. In fact, mitigating or eliminating corrosion in any industry is nearly impossible without a corrosion assessment.

Corrosion inspections are performed for several reasons. Sometimes, during the material selection process for industrial applications, it is necessary to evaluate different kinds of materials in a particular environment. Evaluating new alloys in different types of environments to compare with traditional commercial alloys; estimating the effectiveness of inhibitors in reducing the corrosion rate of metals; understanding corrosion mechanisms are other reasons.

Corrosion testing generally falls into two broad categories: laboratory testing and field testing, each of which has its advantages and disadvantages. For example, the environmental conditions in real applications are different from those in a laboratory environment. Therefore, it is difficult to extrapolate the results of laboratory tests to an industrial setting. On the other hand, in laboratory tests, the corrosiveness of the environment can be accelerated to obtain faster results, which is not possible in field tests.

Laboratory Corrosion Testing

immersion test

One of the common and simple methods in laboratory testing is the immersion test. In this test, the procedure of which is spelled out by ASTM and NACE, the weight of a dry specimen is measured by an analytical balance before and after exposure to a corrosive environment for a specified period of time. Before and after weighing the samples, specific preparations should be made to remove any corrosion products or organic contaminants. The corrosion resistance of a sample is usually calculated as the corrosion rate in terms of weight loss or thickness loss in mils per year (0.001 inch) or millimeters per year (mm/year). Results depend on the type of metal tested (specific gravity), exposed surface area and test duration factors.

Visual inspection

Some visual inspection is also recommended to assess localized corrosion such as pitting or spalling. In addition, optical or scanning electron microscopy; elemental and compositional analysis, such as energy-dispersive X-ray spectroscopy (EDX); X-ray diffraction; and energy-dispersive X-ray spectroscopy (XPS) are useful techniques to more accurately evaluate corroded surfaces and corrosion products.

There are several ways to evaluate the pitting of the sample under test. Determining the pit density (the number of pits within a given surface area) or the pitting coefficient (the ratio of the depth of the deepest pit divided by the value of thickness loss due to uniform corrosion) are two important methods for assessing pitting corrosion. There are different types of utilities to measure pit depth. When a pit Thickness Gauge cannot be used, a contour gauge can be used to profile the pit depth.

Salt Spray/Fog Test

Some test samples and procedures are designed to evaluate specific types of corrosion such as crevice corrosion, stress corrosion cracking and erosion corrosion. Atmospheric corrosion of coated samples can be checked by salt spray or fog testing. Here, a 5% NaCl solution is atomized in a chamber regulated at 95°F (35°C). The time a sample can resist corrosion is the criterion used to understand the durability of the test sample. Although the environment in the salt spray test was an accelerated marine atmosphere, it is believed that the salt spray results can be extrapolated to other atmospheric environments.

Aging test

In another atmospheric method called the weathering test, samples of organic paint coatings are checked for durability by exposing them to ultraviolet light and hydronic heating as well as corrosive environments.

Electrochemical test

Electrochemical testing is another type of laboratory test that can provide valuable information about the electrochemical reactions of corrosion and the mechanisms behind them. A potentiostat is commonly used to perform such tests. Typically a three-electrode setup is used, consisting of a working electrode, a reference electrode and a counter (auxiliary) electrode. Potential, current and time are three important parameters in electrochemical testing. In these tests, the applied potential is typically swept over a range and the current is measured.

There are various types of electrochemical corrosion tests. Each type serves a specific purpose.

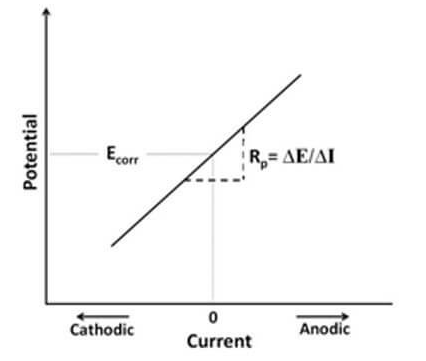

Linear Polarization Resistance: A simple electrochemical corrosion test is linear polarization resistance, where when the applied potential ranges from below the corrosion potential to above the corrosion potential (Ecole). The slope of the current vs. potential curve shows the polarization resistance, This is inversely proportional to the corrosion rate. This test is very quick and straightforward and is generally accepted as a non-destructive test. Furthermore, this method is very useful for measuring extremely low corrosion rates. This is important in some industrial systems, such as food processing, nuclear power, and pharmaceutical equipment.

This figure shows the LPR curve. The slope of the line shows the polarization resistance (Rp).

Potentiodynamic Polarization Test: The passivation behavior of active-passive metals such as stainless steel can be assessed by potentiodynamic polarization testing. In this method, the potential range of scanning is very wide. Critical current density, passive potential and passive current density can be extracted from this test.

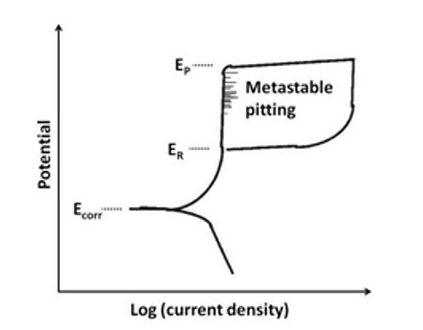

Circular Polarization: This is another test used to determine the tendency of active-passive metals to localized crevice or pitting. In this test, the sweep direction of the applied potential was reversed at certain potentials across the passive region. The intersection between forward and backward scans shows the trend and intensity of localized corrosion.

该图显示了用于评估点蚀的循环极化曲线。更少的ER和较大的亚稳点蚀回路显示出对点蚀的敏感性。

电化学电位动力学再激活 (EPR) 测试:这是另一种被建议用于预测不锈钢敏化或晶间腐蚀趋势的测试。与ASTM A-262建议的其他常规晶间腐蚀测试相比,电化学电位动力再活化非常简单快捷。

上述电化学测试是在直流条件下进行的。然而,了解亥姆霍兹双层(可以充当电容)或金属表面上抑制剂的吸附(可以充当电感)需要替代电流。这种类型的测试称为电化学阻抗谱(EIS),可以揭示有关腐蚀机制的宝贵信息。此外,当电化学系统中的整体电阻非常高时,例如当样品被厚有机涂层覆盖或浸入有机溶液中时,该技术非常有用。

现场腐蚀测试

腐蚀试样

安装腐蚀试样是监测管道、热交换器和储罐腐蚀的一种非常简单和常用的方法。优惠券插入带有优惠券持有人的工厂或设备一段时间。(有关优惠券持有人的更多信息,请参阅腐蚀优惠券持有人如何保护您的宝贵资产。尽管许多因素会影响试样安装的位置,但试样通常放置在预计会严重腐蚀的位置。取回优惠券后,将考虑重量和尺寸的变化或目视检查。这种方法的缺点是不可能加速环境条件以达到更快的结果。

超声波厚度监测

超声测厚仪(UT)是用于监测管道或储罐内部腐蚀的仪器之一。超声波由超声波换能器产生,穿过后壁并反射回源,因此可以通过测量反射时间和考虑被测材料中声波的速度来计算金属的厚度。当无法接触到试样的两侧时,UT量规测试很有用。(有关超声检测的更多信息,请参见 CUI 工艺管道检测技术(第2部分)。

电阻测试

电阻(ER)探头用于测量试样的腐蚀速率,特别是当需要在线腐蚀速率时。当金属在环境中腐蚀时,由于横截面的厚度或表面积减小,其电阻会增加。通过测量金属电阻随时间的变化,可以确定金属溶解速率,并以mpy或mm/yr计算腐蚀速率。ER探头可用于任何类型的环境,包括水溶液、油(碳氢化合物)、土壤、气体和大气。探头可以生产成各种几何形状,具体取决于金属的类型、系统和被测环境。

There are many other tests used to monitor structures protected from corrosion through cathodic protection. Most of these tests are based on the measurement of the electrochemical potential of the structure and the environment.