Automatic Film Applicator Case | Coating Polymer Solutions on Silicon Wafers

Many application cases of nbchao Automatic Film Applicator are the application of film experiments on silicon wafers. In solar cells, transistors, semiconductors, photovoltaic power generation, integrated circuits, electronic components, LED lighting and other industries, silicon wafers are an important raw material, and the performance of silicon wafers has a great impact on the functionality of the final product. Usually a slice of monocrystalline silicon. The original performance of silicon wafers has a certain limit, but as an important raw material, many industry researchers use silicon wafers as substrate raw materials and conduct various modification studies on them to achieve better performance. For example, there are many research experiments on "Ultraamphiphilic Silicon Wafer Interface and Its Application in Polymer Film Preparation" by Jiang Lei, a researcher at the Institute of Physics and Chemistry of the Chinese Academy of Sciences, and a team of field associate researchers at the Institute of Chemistry of the Chinese Academy of Sciences.

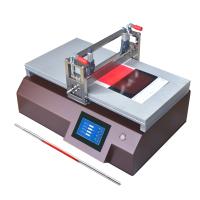

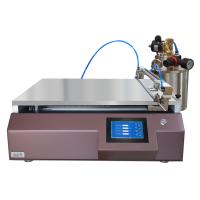

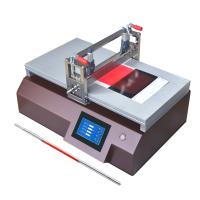

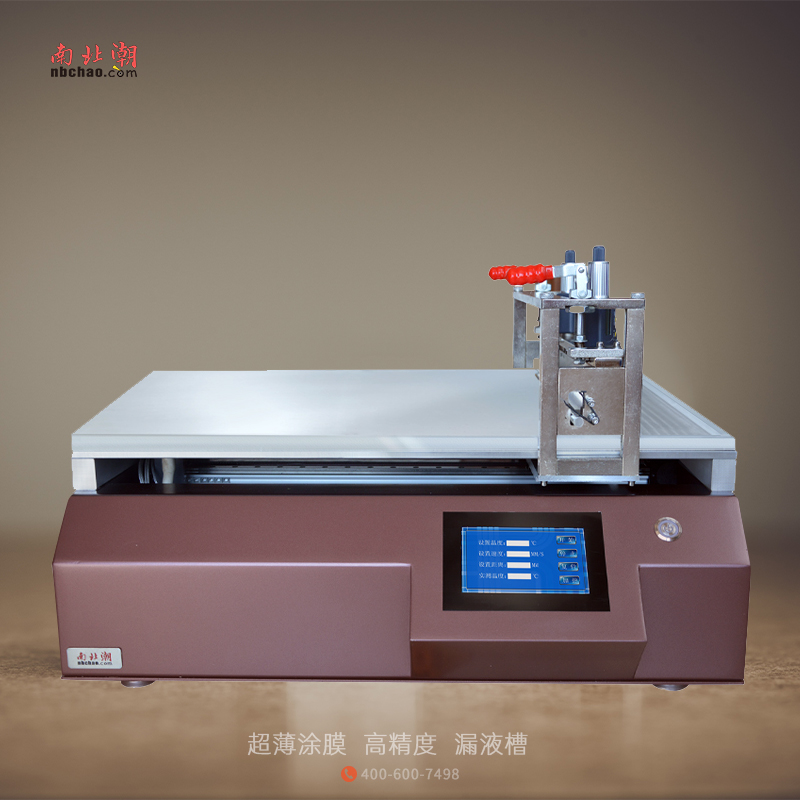

In this case, the user also makes a film on the silicon wafer to study its performance. Specifically, the polymer solution is applied on the silicon wafer. The film after drying is a few microns, that is, the wet film that is scraped is about ten microns. In addition, due to the small size of the silicon wafer itself in the experiment, the Film thickness is not thick, and some heating and drying is required, so the nbchao technology recommends the universal material Automatic Film Applicator, which has four functions of heating vacuum adsorption scraper rod. The wire rod can meet the high-precision film Spreader. For less than 40μm, use imported wire rod to scrape The accuracy of the coating is higher, and the scraper can meet the user's Miscellaneous experiment, especially for the uncertainty of Film thickness, the film thickness of the scraping can be adjusted freely. Vacuum adsorption can play a good role in fixing and maintaining the substrate, so the four-in-one laboratory Automatic Film Applicator is more in line with the user request of this case.

In order to further understand the detailed technical parameters of the four-in-one Automatic Film Applicator, the editor shares the detailed technical parameters below for user reference:

| 制膜打样 - 制膜 | |

| TBJ-GDHO-GCXB Vacuum adsorption wire rod scraper heating Spreader testing machine |

| Specifications: scraper Spreader accuracy ± 10μm, scraper Spreader Film thickness range 0~ 5000μm, Spreader rate 2~ 200mm/s, Coating size 300 * 400mm, vacuum adsorption size 300 * 400mm (customizable), vacuum aperture Φ1.2mm, vacuum aperture 20 * 20mm, scraper Spreader width 200mm (optional 300mm), Spreader stick Spreader width 300mm (determine Spreader Film thickness according to bar model), host power supply 220V 50HZ, external dimensions 630 * 410 * 520mm, weight 65KG, speed control stepless speed change, base plate material aluminum alloy, heating temperature range RT +~ 200 ℃, Temperature uniformity ± 3 ℃, power 1500W, Vacuumpump size 380 * 180 * 280mm, optional accessories liquid leakage tank, substrate fixing fixture, fine-tuning horizontal height support foot device, Glass plate, silicone pad and weight (for Spreader substrate Film thickness uneven application), film width control baffle, customizable function Jet system device, UV solid inclusion device, automatic inking system, scraper material Aluminum alloy, scraper size 214 * 76 * 100mm, scraper weight 500g, Spreader rod specification standard 1 domestic (CN) bar | |

| TBJ-X3 Vacuum adsorption wire rod scraper heating integrated Spreader testing machine |

| Specifications: Spreader accuracy ± 0.003mm, Spreader Film thickness range 0~ 10mm scraper can be lifted and lowered, Spreader rate 2~ 200mm/s, Coating size 300 * 400mm, Spreader speed digital display, different speeds, vacuum adsorption size 300 * 400mm (can be customized), vacuum aperture Φ1.2mm, vacuum aperture 20 * 20mm, scraper length, Spreader rod specification accuracy 0.001mm, effective Spreader width 300mm (determine Spreader Film thickness according to the bar model), host power supply 220V 50HZ, external size 630 * 410 * 520mm, weight net weight 65KG, speed control stepless speed change, base plate material aluminum alloy, heating temperature range RT +~ 200 ℃, Temperature uniformity ± 3 ℃, power 1500W, Vacuumpump size 380 * 180 * 280mm, optional accessories Leakage tank, substrate fixing fixture, fine-tuning horizontal height support foot device, Glass plate, silicone pad and weight (for Spreader substrate Film thickness uneven application), film width control baffle, Spreader accuracy 0.001mm, customizable functions Jet system device, UV solid inclusion device, automatic inking system | |

| TBJ-X3-XB Vacuum adsorption wire rod scraper heating integrated Spreader testing machine |

| Specifications: scraper Spreader accuracy ± 0.003mm, Spreader Film thickness range 0~ 10mm scraper can be lifted and lowered, Spreader rate 2~ 200mm/s, Coating size 300 * 400mm, Spreader speed digital display, different speeds, vacuum adsorption size 300 * 400mm (can be customized), vacuum aperture Φ1.2mm, vacuum aperture 20 * 20mm, scraper length, Spreader rod specification 1 domestic (CN) bar + 1 imported bar with a precision of up to 1μm, effective Spreader width 300mm (determined according to the bar model) Spreader Film thickness), host power supply 220V 50HZ, external size 630 * 410 * 520mm, weight net weight 65KG, speed control stepless speed change, bottom plate material aluminum alloy, heating temperature range RT +~ 200 ℃, Temperature uniformity ± 3 ℃, power 1500W, Vacuumpump size 380 * 180 * 280mm, optional accessories Leakage tank, substrate fixing fixture, fine-tuning horizontal height support foot device, Glass plate, silicone pad and weight (for Spreader substrate Film thickness uneven application) , film width control baffle, can be customized function jet system device, UV solid device, automatic ink system | |

If you have or do not understand the above parameters and want to know more, you can have in-depth communication with nbchao technical engineers to obtain a more comprehensive knowledge of Automatic Film Applicator.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research