Definition of pigment PVC formula, use of pigment

What are pigments?

The "Pigment Handbook" (Pigment Handbook, 1987 edition) published in the United States is defined as "a granular substance that is not dissolved by the dispersion medium, nor does it physically or chemically react with the dispersion medium, and its particle size ranges from extremely fine colloidal particles (approx. 0.01 μm) to larger particles (about 100 μm)”.

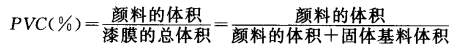

One of the most important factors in paint formulation design is the ratio of base material to pigment. Because the coating is expressed by thickness, that is, the volume-related quantity is used to reflect the performance of the coating. In the coating film, the solid-solid dispersion system between the film-forming material (substrate) and the pigment is distributed in the form of volume. After the film-forming material fills the gap between the pigments, the excess volume of the substrate is an important basis for judging the performance of the coating film. Generally, the volume concentration of the pigment in the dry film is called "pigment volume concentration", expressed in PVC:

The properties of many films change suddenly when PVC is added. The PVC at which this change occurs is called the critical pigment volume concentration (CPVC).

The main characteristic of the pigment volume concentration is that when the pigment particles are below the CPVC, there is little contact, while when the pigment particles are above the CPVC, the substrate is replaced by air. At the volume concentration of the unique pigments on both sides, the properties of the film change dramatically.

Gloss has a lot to do with PVC. In general, unpigmented films have high gloss. At first, a small amount of pigment has no effect on the gloss, but when the PVC is higher than 6%~9%, the gloss gradually decreases in the range of PVC and CPVC. Low gloss surfaces have better intercoat adhesion than smooth bright surfaces, so it is good to make the PVC of the primer larger than the CPVC.

According to the use of pigments in coatings, they can be divided into four categories: ① colored pigments; 2. body pigments; ③ anti-rust pigments; ④ special function pigments.

- 1Importance and determination method of paraffin resistance of pigments

- 2How to determine pigment lightfastness

- 3How to assess the dispersion of pigments?

- 4Pigment acid alkalinity test

- 5What are the four major categories of coatings?

- 6How are pigment flocculation and sedimentation formed?

- 7How to increase the redispersion effect of pigment surface area?

- 8Pigment related ASTM testing standards

- 9Difference between pigment and dyestuff