Roughness and Surface Roughness

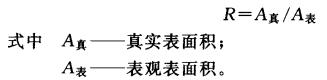

Roughness is a characteristic parameter of the surface, which reflects the roughness of the solid surface, represented by R

The test shows that only the R value of the newly melted glass surface and the newly torn mica surface is approximately equal to 1, the R value of the metal surface after careful mechanical polishing is still between 1.5 and 2, and the R value of the metal surface after sandblasting can be 6 ~8 between.

Appropriate surface roughness can improve the adhesion between the coating film and the substrate. The tests further showed that the adhesion strength is not only related to the surface roughness, but also closely related to the difference in surface geometry due to different methods of roughening the surface. Generally speaking, to ensure adhesion, it is necessary to ensure sufficient surface roughness, but the roughness should not be too large. If the surface is too rough, it will not be well saturated by the coating. Air and water trapped in recesses can have a negative effect on the adhesion of the coating film.

The rough surface can not only double the contact area to achieve the anchoring effect, but also the capillary-shaped voids can help the coating expand due to capillary action and improve the adhesion strength. At the same time, the surface treatment process of the substrate can also clean the surface of the substrate, activate the state of the metal surface, and further enhance the adhesion between the coating and the substrate.

- 1Influence of surface roughness of parts

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 4Evaluation of steel surface roughness

- 5The relationship between abrasive and surface roughness

- 6Which industries need to use surface roughness meters?

- 7Surface roughness measurement

- 8What are the application fields of surface roughness meter?

- 9What are the main manifestations of the influence of surface roughness on parts?

-

-

-

-

-

KAIRDA NDT151P Roughness Gauge$ 810.00

-