The relationship between abrasive and surface roughness

Abstract:

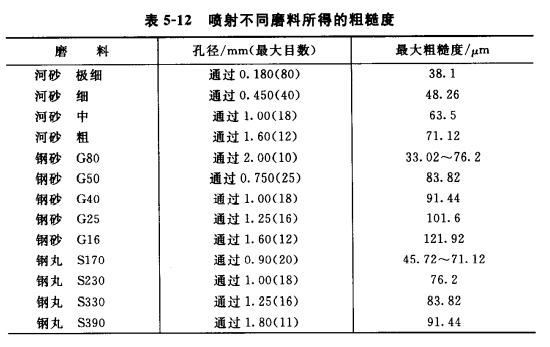

本文探讨了磨料与表面粗糙度之间的关系。表面粗糙度指的是加工表面的微观几何特征,包括最大粗糙度和平均粗糙度。最大粗糙度是指任意波峰与附近波谷之间的最大垂直距离,而平均粗糙度是指表面上每一点到中心线的平均垂直距离。工件表面的粗糙度受多种因素影响,包括磨料的粒度、形状、材质、喷涂角度、距离和作用时间,其中磨料的粒度对粗糙度有显著影响。

Surface roughness refers to the micro-geometric features formed by small distances and grooves on the machined surface. Roughness can be divided into maximum roughness and average roughness (also known as centerline average roughness). The maximum roughness refers to the maximum vertical distance between any peak and the trough near the straight line, and the average roughness refers to the average vertical distance from each point on the polished surface to the center line.

The roughness of the workpiece surface is related to the process parameters such as the particle size, shape, material, spraying angle, distance, and action time of the abrasive. Abrasive particle size has a great influence on roughness.

Products required

Relevant knowledge

- 1Influence of surface roughness of parts

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 4Evaluation of steel surface roughness

- 5Roughness and Surface Roughness

- 6Which industries need to use surface roughness meters?

- 7Surface roughness measurement

- 8What are the application fields of surface roughness meter?

- 9What are the main manifestations of the influence of surface roughness on parts?

Guess you like it

-

-

-

-

-

KAIRDA NDT151P Roughness Gauge$ 810.00

-