Evaluation of steel surface roughness

In order to obtain a coating with good performance, after the steel surface is sprayed, it must not only meet the cleanliness specified in the technical specification, but also have a certain surface roughness, so that the coating can have better adhesion on the steel surface.

The international standard ISO 8503 consists of four parts to evaluate the surface roughness characteristics of steel after blast cleaning.

1SO 8502-1 Technical requirements and definitions of ISO surface roughness comparison samples. ISO 8503-2 Classification of surface roughness of steel after blast cleaning - Comparative sample method.

ISO 8503—3 ISO reference block calibration and surface roughness measurement method - Microscope focusing method.

ISO 8503-4 Method for calibration of ISO reference blocks and determination of surface roughness - stylus method.

my country's national standard GB/T 13288 "Assessment of Surface Roughness Grade of Steel before Painting (Comparison Plate Method)" was formulated with reference to ISO 8503.

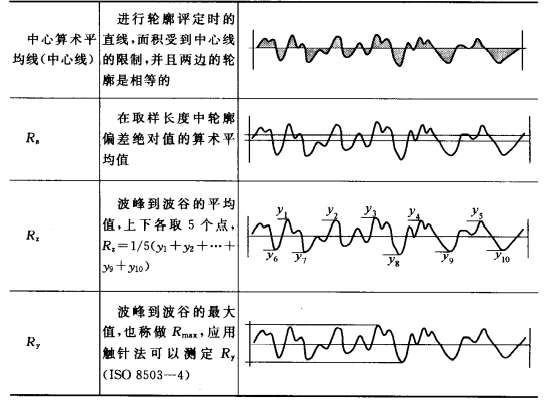

There are several definitions of surface roughness.

- 1Influence of surface roughness of parts

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 4The relationship between abrasive and surface roughness

- 5Roughness and Surface Roughness

- 6Which industries need to use surface roughness meters?

- 7Surface roughness measurement

- 8What are the application fields of surface roughness meter?

- 9What are the main manifestations of the influence of surface roughness on parts?

-

-

KAIRDA NDT151P Roughness Gauge$ 810.00

-

-

-

-