What are the ASTM D3359 Method B and ISO 2409 compliant paint film scribes?

Adhesion cross-hatch test standards mainly include ASTM D3359 Method B and ISO 2409. The test methods and descriptions of the two are basically the same, but the description order of the adhesion level is just opposite. ASTM D 3359 is 5B~0B (from good to bad), while ISO 2409 is 0~5 (from good to bad). Chinese national standard GB/T 9286-1998 is equivalent to ISO2409:1992. The following mainly introduces the test method of ISO 2409.

There are two types of knives used in the ISO 2409 cross-cut method: multi-edged and single-edged. Due to the dry film thickness > 120pm or the hard coating film, the multi-edged tool is not easy to cut smoothly, and it is recommended to use a single-edged tool. In order to avoid human errors, an electric cross-cut adhesion Tester has been developed, which can automatically cross-cut and the tool pressure can be adjusted in advance. The use of single-blade tools also requires instruments of different spacing. Transparent pressure-sensitive tape and X2 or X3 magnifying glass are also indispensable test materials.

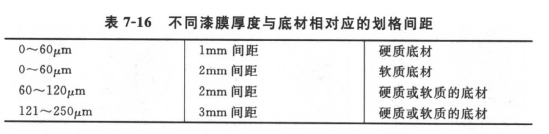

Different paint films determine different grid spacing, and the hardness of the substrate also has an impact.

The testing process is as follows:

1. Measure the paint film to determine the appropriate cutting distance;

2. The cutting speed of the paint film should be uniform, the pressure should be stable, the spacing should be appropriate, and the knife should see the iron (straight through the surface of the substrate);

3. Repeat the above operation to cut the paint film in parallel and equal numbers on 90 corners again to form a zigzag shape;

4. Sweep the surface with a soft brush, roll off the tape in a steady state, and cut out a length of 75mm;

5. Place the tape on the grid parallel to the score line from the middle of the tape, leaving at least 20mm of length outside the grid for easy grasping by hand, and smooth the tape with your fingers;

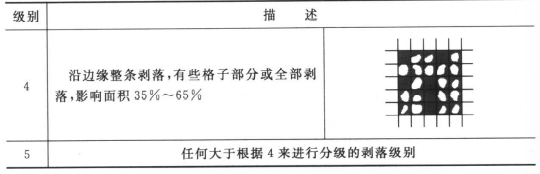

6. Grasp one end of the tape, tear the tape at an angle close to 60 degrees within 0.5~1.0 seconds, and check the state of the cut part with the tape as a reference. According to ISO 12944-46, a grade 0 or 1 is acceptable.

ISO12944 stipulates that the adhesion needs to reach grade 1 to be qualified; in GB/T 9286-1998, the first three grades are satisfactory, and the first three grades are also used when passing/failing.

- 1The principle, application, test procedure and result evaluation of cross-cut Tester

- 2Drawing adhesion test purpose, operation method and common problem

吉姆·布朗

- 3Two Methods of Adhesion Testing

- 4What are the characteristics of unsaturated polyester coatings?

- 5Drawing method test principle [with schematic diagram]

- 6Standard Test Method for Adhesion

- 7Paint Adhesion Test - Paint Film Scratch

- 8What performance subjects should be tested for amino alkyd resin coatings? How to judge the results?

- 9Adhesion Test of Coated Thermal Insulation Glass with Paint Film Scratch