Are hardness and wear resistance the same?

Abrasion resistance describes the ability of a material to resist loss of material through mechanical action. For example, the threads on a tire start to wear out after repeated prolonged use. Note that materials can be hard wearing and tough, but not inherently hard. Hard materials are also wear-resistant, but not particularly tough. Toughness, in this context, refers to the ability of a material to absorb energy or undergo deformation or mechanical stress without fracture or sustained deformation.

Tires, like ceramics, can be very wear resistant, but that doesn't make them hard. They are tough because even when the tire is permanently deformed, it rarely tears or breaks. Ceramics are also wear resistant, fine ceramics are more resistant to chemical and abrasive wear than other ceramics. The Abrasion Resistance Test for Ceramic Materials measures the abrasion resistance/resistance of ceramics.

Hardness generally refers to the ability of a material to withstand or resist permanent deformation. If a material is resistant to indentation, scratching, bending or cutting, we can say that it has good hardness qualities.

In general, the higher the yield stress of a ceramic, the more likely the material will crack under an indenter. Hardness is more or less a material's response to the conditions being tested. For example, a fine-grained material is generally harder than a coarse-grained material of the same composition. This is because coarse-grained varieties are more prone to partially broken kernels than fine-grained varieties.

- 1Working principle and application of UV coating Cupping testing device

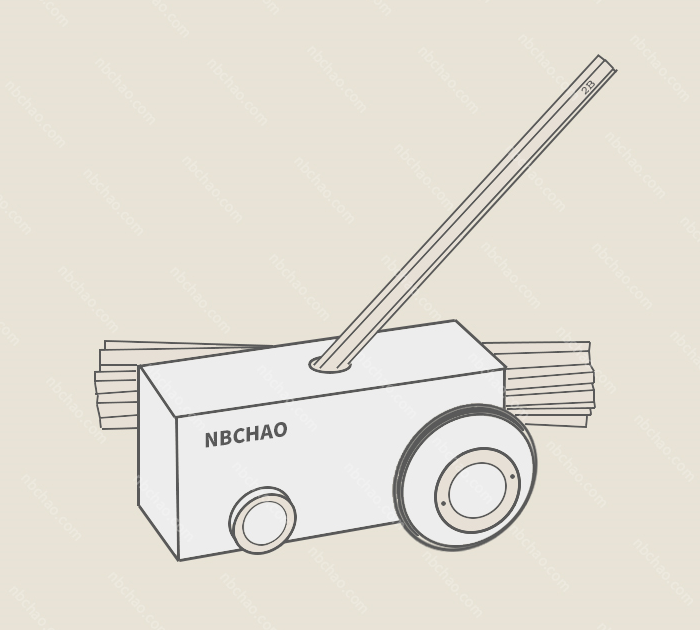

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings