Causes and Solutions of Coating Cracking, Pinholes and Leakage

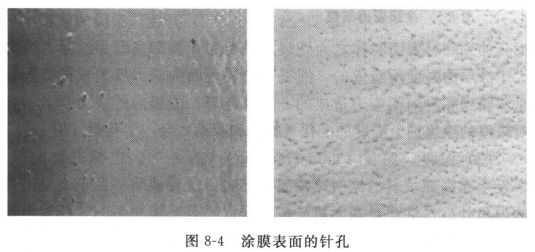

What are coating pinholes and leaks?

If the spraying technique is not good, such as too high air pressure, too thick paint film, excessive ventilation or strong wind, and too far away when spraying, pits, pinholes and leaks will appear.

Metal zinc / aluminum coatings and inorganic zinc-rich primers are prone to pinholes. The surface of these coatings is porous. When the backcoat is applied, the air in the pores of the surface can escape and leave pinholes.

The corrective measure is to spray a layer of closed connection paint, generally about 30 microns, which does not require good coverage. Instead, just mist spray coverage, followed by an all-over normal uniform spray. This is the so-called mist spray/system spray technology.

For pinhole repairs, sand them down and seal these imperfections with a paint containing aluminum powder or micaceous iron to achieve the correct film thickness. However, if pinholes are severe, it's often difficult to get rid of them. The air in between will escape in the new coating and new pinholes will appear. At this time, removing the coating and re-spraying is a method.

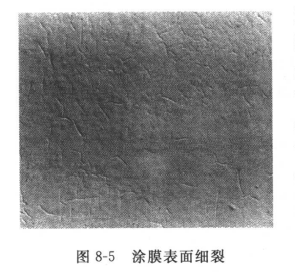

What is coating cracking?

In many cases, cracking is caused by the formulation of the coating itself, or by aging and weathering. There are three main phenomena of cracks: surface cracks, cracks and cracks.

(1) The surface is finely cracked. Cracks can be defined as small cracks in the surface of the coating. This is a surface phenomenon and will not penetrate deep into the coating. Some cracks are invisible to the naked eye and can only be seen with a magnifying glass. In most cases, tiny cracks are caused by a poor match of resin and pigment. Although fine cracks will not penetrate into the interior of the substrate, surface fine cracks will be further aggravated due to climate change, wind and rain, cold and heat, etc.

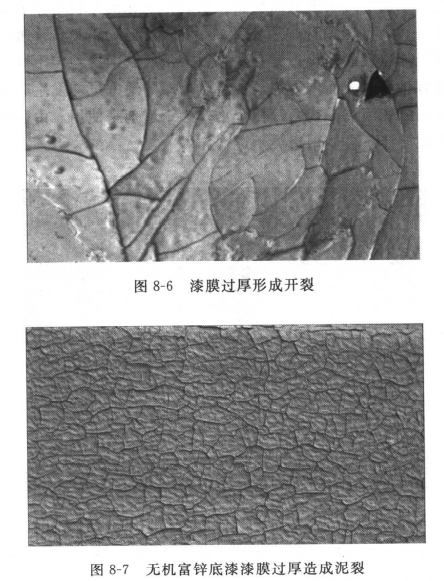

(2) cracking. When cracks in the coating extend from the surface to the surface of the substrate it is called cracking. Whether it is fine cracking or cracking, it is caused by the stress of the paint film greater than the strength of the coating. Fine cracking is caused by stress on the coating surface; cracking is caused by stress between the paint film and the substrate. The thicker the paint film, the greater the stress in the paint film. Relatively thick paint films can crack in combination with temperature changes (expansion and contraction).

(3) Mud cracks, also known as cracks, usually occur in the construction of thick paint films with high color matching fillers. This defect is more common in poorly ventilated interior corners. Water-based coatings and inorganic silicate zinc-rich coatings are high-filler types and are prone to cracking. Cracking is also an immediate reaction that occurs after the solvent or water has evaporated from the paint. This is because the color rendering ratio of zinc powder to the base color is high. When cracking occurs, the coating will lose adhesion and will need to be completely removed before recoating.

- 1What is pinholing?

- 2Why does the coating have orange peel defects? How to solve sagging and leakage?

- 3Coating Leakage and Pinholes

托马斯·贝利

- 4What is Holiday Detector?

- 5Analysis of cracking and peeling defects in Coated steel coating construction

- 6How to measure the heat resistance of paint film?

- 7Solutions to film defects caused by coating cracks and cracks

- 8Analysis and countermeasures of film defects caused by pinholing and bubble holes?