How to avoid or slow down the whitening and chalking of the paint film?

whitish

The phenomenon of dull turbidity or translucent milky white in the drying process of the paint film is called whitish or whitening. Whitening can be divided into wet whitening and resin whitening.

Wet whitening is more common in volatile coatings, mainly in construction in wet weather, that is, when the humidity is greater than 80%. As the solvent in the paint film absorbs heat when it volatilizes, the air temperature near the paint film interface suddenly drops below the "dew point". At this time, the water precipitated in the air condenses on the surface of the paint film, and a small amount of water dissolves in the paint film. As the solvent continues to volatilize, the water on the surface of the paint film continues to increase, forming a two-phase emulsion, and the light is refracted through the two phases, so it looks white. Therefore, in order to prevent the volatile paint from turning white during construction in a humid environment, a small amount of moisture-proofing agent or high-boiling solvent can be added to the paint before construction. After the paint film turns white, such as nitro paint, you can use a rag dipped in a little nitro thinner to wipe the surface of the paint film to eliminate the whitening phenomenon. The construction of nitro paint should keep the relative humidity below 75% and the temperature above 12°C.

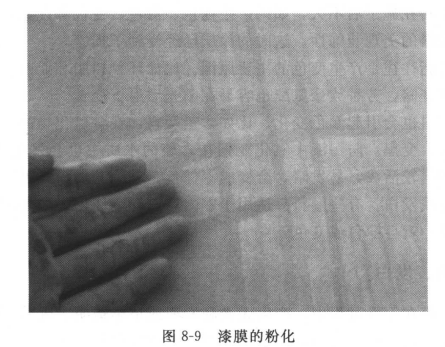

chalking

Chalking is strictly a surface phenomenon caused by solar UV rays (a small amount of chalking in shaded areas). However, all reactants in the air, such as moisture, oxidation, and air pollution, are part of the pulverization process. They cause the binders like resins in the paint to degrade, leaving just the pigment on the surface, like dust.

Epoxy coatings are typical coatings that chalk quickly. Alkyd paint is better. Other resins, such as acrylic resin paints, alkyd or epoxy modified acrylic paints, polyurethane (aliphatic) paints, silicone alkyd paints, silicone acrylic paints, especially fluorocarbon paints and polysiloxane paints, have excellent Excellent weather resistance, less affected by solar radiation, and has outstanding color and gloss retention properties.

Pigments also have an effect on chalking, such as titanium dioxide. The rutile-type titanium dioxide is very easy to crush in all resins, while the coating prepared by rutile-type dioxide has good weather resistance.

Aluminum powder, mica iron, etc., due to the layered structure in the coating, can reduce the sun's ultraviolet rays, thereby reducing chalking. Adding UV absorbers to the topcoat also works well.

- 1Is there any easy way to reduce the blushing phenomenon of shellac paint?

- 2Why do film blushing often occur when using nitro paint and shellac paint, what is the reason and how to prevent it?

- 3What is the chalking of the paint film and how is it determined?

- 4In a humid environment, which solvents can be used to prevent blushing?