CS-810 Desktop Spectrophotometer Application Case Cleaner Color Detection

Detergent is a liquid cleaning product used to wash clothes, utensils or furniture. CHINA's detergent industry has become one of the pillar industries of CHINA's light industry. At present, there are 100 synthetic detergent manufacturers in CHINA's detergent industry, with an annual production capacity of 2.9 million tons. As daily necessities, with the improvement of people's requirements for the quality of life cleanliness, the demand is also increasing.

Some traditional companies are used to monitoring the quality of products by visually identifying the color difference of detergents. However, the naked eye is not accurate in identifying the color difference, and the visually detected color will vary from person to person, from place to place, and from time to time, and the efficiency is also very high. Low. Customers who have requirements will not recognize the product quality after visually identifying the color difference. Therefore, more and more companies are now using Spectrophotometer s for testing in order to produce high-quality cleaners and control product quality. This high-precision technology is introduced. The device performs color monitoring of cleaning agents.

So which Spectrophotometer can meet the needs? Today, take Caipu’s CS-810 desktop Spectrophotometer as an example. This transmission liquid Spectrophotometer can meet the testing requirements of cleaning agents. Let's see how to test?

CS-810 desktop Spectrophotometer /Colorimeter (as shown in the picture) is a high-performance spectrometer specially used to measure liquid transmittance, absorbance, concentration, chromaticity and other parameters. In addition to measuring liquid transmission, the instrument also includes APHA/PtCo (APHA/Platinum Cobalt) and Gardner (Gardner Index) Colorimeters; for products such as resins, solvents, acids, perfumes, varnishes; Saybolt colorimetry Scale for measuring gasoline, white oil, kerosene, lubricating oil and paraffin oil. The instrument can fully meet the requirements of detergent Lab value and color difference measurement.

To illustrate the difference between instrument recognition and visual recognition, a practical demonstration of overmeasurement is as follows:

step 1:

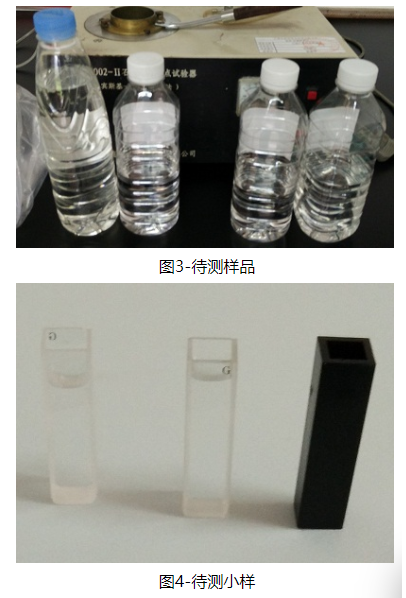

First prepare the detergent samples to be tested (as shown in Figure 3), the two sample chambers on the left are very different from the naked eye, and the two samples on the right are transparent reagents. Chromatic aberrations cannot be discerned with the naked eye. First, the transparent samples to be tested are respectively sampled for detection (as shown in Figure 4);

Step 2:

Install the instrument, connect the instrument to the computer, turn on the instrument for black and white calibration, and then open the sample chamber (as shown in Figure 5);

Step 3:

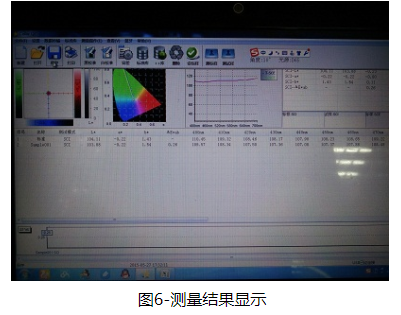

Put the standard sample to be tested and the sample to be tested into the sample chamber for measurement, and the measurement result can be obtained and displayed on the computer (as shown in Figure 6), the color difference value is 0.26;

Step 4:

Repeat the above steps to measure two samples that look very different to the naked eye, and the color difference of the measurement result is 0.59.

Specific data such as the laboratory value and color difference value of the standard sample of the detergent to be tested and the test sample can be visually seen through the results displayed by the computer. More information and cases about Spectrophotometer can be communicated with Beichao Technology.

- 1Colorimeter Selection Guide [NBchao Brief Version]

- 2What is the difference between tristimulus Colorimeter and Colorimeter?

- 3What is the difference between Color Reader and Colorimeter?

- 4How does Colorimeter detect particulate matter (PM) color differences?

- 5Application of Colorimeters in paint&Coating color difference detection

- 6Several selection points about food Colorimeters

- 7Selection points of portable Spectrophotometer

- 8Non-contact Colorimeter selection considerations

- 9Color Measurement Challenges Faced by Manufacturers in the Metals Industry

-

-

-

CHINA LS176 Colorimeter Colorimeter$ 632.00

-

-

CHNSPEC CRX-51 Non-Contact Colorimeter$ 11243.00

-