How to effectively control ink viscosity?

Ink viscosity control can be divided into two stages. The first stage is to accurately measure the ink viscosity and adjust the ink to the desired viscosity. The second stage is to maintain the ink viscosity at the desired level. Accurate measurement is only the beginning, what good is viscosity if it cannot be maintained in print production? Being able to maintain ink viscosity during production is the hard part. Effective print production can only be achieved if ink viscosity can be controlled. Otherwise, the desired print quality might not be achieved, or the quality might be inconsistent. lead to unnecessary waste.

So, how do we effectively control ink viscosity? There are three main types of measuring instruments that can help us, they are 1.Ford Viscosity Cup, Zahn cup. 2. Falling ball viscometer 3. Vibration viscometer.

Ford Viscosity Cup, Zahn cup

The most traditional measurement method. Fill the cup with ink, then use a stopwatch to measure the time (usually in seconds) it takes for the ink to drain. A longer time it takes for the ink to drain indicates a higher viscosity and vice versa. This method is considered an easy, inexpensive method of measurement.

Ford Viscosity Cups and Zahn cups are low tolerance instruments. The tolerance deviation is usually 5% to 10%, which means that for a 20 second measurement, it can be off by 1~2 seconds. Furthermore, this measurement method is overly dependent on humans. This results in high variability and limited accuracy. This type of measurement method is piecemeal. You measure the viscosity and come back after 30 minutes. During this lag, the ink viscosity may have changed and print quality may be affected.

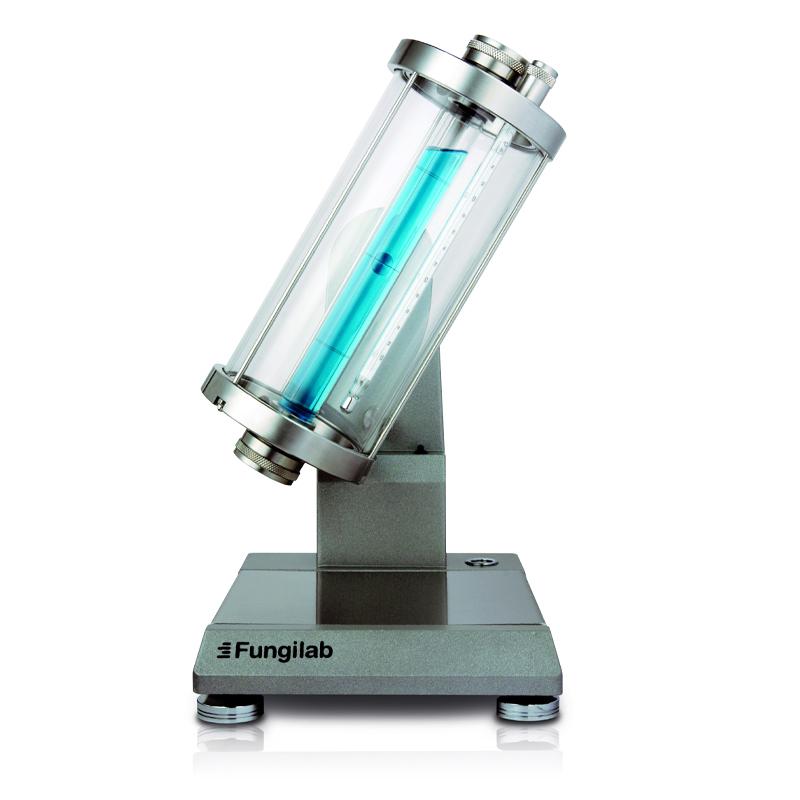

Falling Ball Viscometer

A falling ball viscometer drops a ball of known density and size into a fluid sample and measures the time it takes for the ball to fall to a specific point. The Falling Ball Viscometer uses the same measurement concept as the Ford Viscosity Cup or the Zahn Cup, i.e. measuring flow under gravity. The sensors used to measure the speed of the falling ball will digitize the collected information, thus improving measurement accuracy compared to manual measurements. However, the falling ball viscometer is still a fragmented measurement system, so there will be variance between measurements and between adjustments. Even with room for improvement. Many printers find that a falling ball viscometer is sufficient.

Vibration Viscometer

This is a relatively accurate ink viscosity measurement system currently on the market. To measure viscosity, a vibratory viscometer measures the damping of an oscillating resonator immersed in a sample fluid. Different types of vibrating resonators include quartz crystal resonators, surface acoustic wave resonators, vibrating metal rods, and torsional resonators. Through the damping effect of the ink on the resonator, the system calculates the viscosity value. This measurement method is a continuous measurement method, which means that measurements are made continuously. Unlike the fragmentation methods of Zahn cup and falling ball viscometers, there is no time lag between measurements. So how accurate is this type of system? For example, when we pour 20 grams of solvent into a 25 kg ink tank. Through the vibrating viscometer, it will detect the viscosity change of 0.1 mPa.s. If we convert this to Zahn cup units, it takes about 0.02 seconds. Therefore, such fine measurements are not possible on Zahn cups.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Coating viscosity determination - viscosity cup Yiwen

- 5Working Principle, Classification and Application of Capillary Viscometer

- 6Principle, application and selection of ZAHN5 viscosity cup

- 7Corrugated fibreboard starch viscosity cup its principle, application and selection introduction

- 8Decryption paints original juice viscosity cup, principle, application and selection

- 9Wood lacquer viscosity cup, principle, application and selection introduction