Why do researchers regularly change the wire rod when using the coating machine?

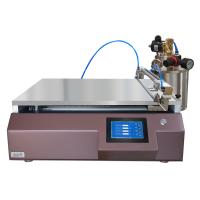

In the past, manual coating was mostly used in general coating experiments, and the coating was uneven and the overall effect was poor. In order to solve these problems, the laboratory coater was conceived and born. The function of the laboratory coater is to facilitate the accurate coating on different substrates by the experimenters, reduce and eliminate the errors caused by human factors such as different coating speeds and pressures. It is mainly used for production experiments of metal foil, glue, paper, and film, and can also be used for other related coating and coating industries.

The reason why the film coating machine needs to replace the wire rod regularly

It is to ensure the accuracy of the coating film.

Wire rods are used as consumables. The frequency of use, the influence of the substrate on the wear of the coating rod, and the maintenance method have a great impact on the replacement cycle. Taking the wire-wound rod as an example, the long-term scraping and proofing will make the wire-wound wire of the wire rod wear and age, resulting in the actual thickness of the coating film becoming smaller. If the cleaning is not clean, the coating film accuracy will be lower, and the extrusion rod is the same. In other words, the longer the use time and the more times of use, the greater the wear and tear caused, resulting in a decrease in the accuracy of the coating film. Therefore, when researchers use the film coating machine, they will regularly replace the wire rods to ensure the accuracy of the coating film. Do you understand?

- 1Advantages of Bar Spreader in corrosion coating prepative

- 2How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 3NVP anode film FAQ and solution

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research