Briefly describe how different industries view product packaging

Today, the packaging industry is booming, with new innovations in packaging materials making transportation safer. Whether in the B2B or B2C industry, everyone relies on these packers to successfully deliver their goods. On the other hand, the industry is under constant pressure to maintain its reputation and commitment. In order to meet the needs and expectations of customers, packagers are conducting various tests on packaging materials according to industry requirements. In this article, we will shed light on different industries and their packaging issues and how to deal with them.

Pharmaceutical Industry – Any product remotely related to healthcare will be considered a pharmaceutical product. The industry produces highly sensitive products that can sometimes be dangerous if consumed by unintended users . Therefore, the manufacturer hands over to the packager the responsibility that the product maintain its composition, shape, and reach the intended consumer.

A very simple example would be pushing down the lid for the syrup. They are specially designed so that children cannot open it. Syrups that were previously packaged in glass bottles are now in PET bottles to avoid any breakage during the transition. Strip packaging of tablets, previously done in paper packs, is now being replaced by foil and blister packs.

E-Commerce – Good packaging is one of the attractions of a great e-commerce brand. In fact, most of them are competing for it as a major aspect. The industry has gone one step further with lots of fancy flexible and corrugated packing. Big brands invest a lot of money in testing machines such as edge crush Testers, abrasion Testers, etc. to check whether their packaging has withstood the shipping conditions. Having attractive print and key information on the packaging impresses the buyers first.

Beverages – Sparkling, Still, Alcoholic, Energy Drinks have always been a consumer favourite. But with the entry of new brands, the mature market of some big brands began to shrink. So, to attract buyers and new markets, they are playing with packaging designs, styles and materials. The new attraction is the spout pouch, which claims to be eco-friendly and low-cost while keeping the contents fresh and hygienic. The colorful bottles with themed shapes definitely stand out. Earlier, beverages were packaged in glass bottles, but now cans, PET bottles, spout bags are replacing traditional bottles. In fact, crown caps are being replaced by ring-pull caps, eliminating the need for corkscrews. This is how beverage packaging is transforming.

Consumer Electronics – The demand for consumer electronics is growing exponentially. With the Internet invading our lives, everything has become smarter. From smartphones to TVs to watches and more, the Internet of Things is the new craze. These devices are smart, thin and delicate enough to be transported. Their packaging plays an important role in product safety. Flip to smart corrugated boxes, linear crates and more. Fillers also need to be tested to ensure product safety. Edge crush Tester, burst strength Tester, peel strength Tester are some of the commonly used machines used to check the soundness of packing.

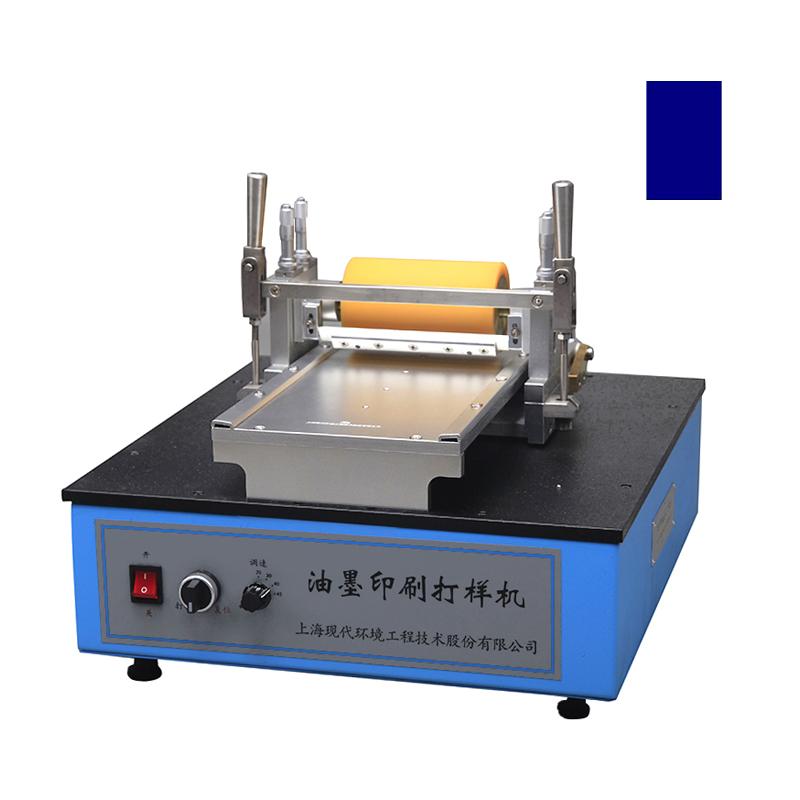

Food Industry - Something that tastes good should first look good. In addition to keeping food safe, hygienic and fresh, they should also represent food in good form. They need to be an attractive print that should not fade from rubbing against other surrounding materials. The seal should not leak, the package should not break, and if the item is packaged in the container, it should not swell or leak. When considering food packaging, there are many aspects to test.

Cosmetics industry – it's all about being attractive. Cosmetic packaging is usually transparent to judge the color of the contents inside. Different packaging styles, such as acrylic boxes, PET cans and bottles, glass bottles, metal tubes, etc. Following a different style while maintaining an aesthetic, they should make the product look good. They are usually impact tested. They should not be broken if dropped from a height . On the other hand, some products have built-in mirrors that shouldn't break on impact. When designing cosmetic packaging, there are many precautions.

-

-

-

-

HP-ZRD-1000 paper softness Tester$ 2515.00

-

-

-

-

-

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Demonstration of RCA wear-resistant tape machine

Air - 《南北潮》

- 7Printing Encasement gloss detection solution

- 8The principle, application, operation and selection of wear-resistant testing and wear-resistant testing machines

- 9How to extend the service life of rubber?