Barrier film primer after UV bonding coating solution [Coating machine case]

foreword

The primer coating of the barrier film and then the UV adhesive coating film experiment is mainly used to prepare and research high-performance protective isolation films, such as display screen protection, UV ultraviolet isolation protective glasses film, gas isolation protection, and other isolation packaging protective films, etc. At present, this kind of research is still relatively extensive. According to the specific experimental needs, NBCHAO Technology recommends a wire rod scraper heating coating machine solution.

User needs

The needs of users are divided into two points:

1. Barrier film primer coating coating, to meet the dry thickness of 1um uniform coating.

2. The thickness of the scraper can be adjusted to carry out UV glue bonding, and the coating width is 300mm.

Selection Analysis

| Substrate | Barrier film (film) | sample | coating, glue |

| film thickness | Dry film 1μm | other requirements | heating |

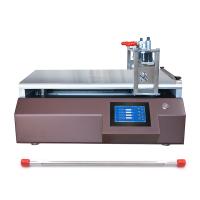

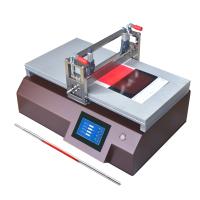

From the point of view of the user’s experimental needs, firstly, the barrier film needs to be scraped and coated with a layer of dry film thickness of 1 μm. On the one hand, the imported wire rod is more accurate for the film preparation below 10 μm. On the other hand, the barrier film As a soft substrate, the ordinary film coating machine cannot be fixed well, and the vacuum adsorption function is needed to maintain its stable flatness; moreover, after scraping the primer coating, it needs to be pasted with UV glue, as the glue , It needs to be kept in a molten state at a certain temperature, so it needs to be equipped with a heating function, and the UV adhesive has a high viscosity and an uncertain film thickness. It can be equipped with an adjustable scraper Applicator to freely adjust the film thickness. Therefore, Beichao Technology recommends wire rod + scraper + heating three-in-one functional coating machine.

Instrument parameters

Let's take a look at the specific parameters of the film coating machine for reference by industry users. Other specifications can be customized.

| Membrane Proofing- Membrane | |

| Domestic TBJ-B4-XB heating wire rod scraper integrated coating testing machine |

| Specification parameters: scraper coating accuracy ±0.003mm, coating thickness range 0.2-10mm, scraper can be raised and lowered, coating rate 2~180mm/s, coating width 300*400mm, coating time digital display, different speeds, time accuracy Control,, Coating rod specifications are equipped with 1 domestic wire rod + 1 imported wire rod with a precision up to 1μm, effective coating width 300mm (determine the coating thickness according to the wire rod model), heating temperature range RT+~200℃, scraper Length 400mm, material/stainless steel, host power supply voltage 220V 50HZ 1700W, external dimensions 626*410*520mm, temperature uniformity ±3°C, net weight 65KG, speed control infinitely variable, base plate made of aluminum alloy, optional accessories leakage tank, base Material fixing fixture, fine-tuning level height support leg device, glass plate, silicone pad and weight (for the application of uneven thickness of coating substrate), coating film width control baffle, customizable function air jet system device, UV solid-holding device , Automatic ink filling system, wire bar coating accuracy 1μm | |

The above is the selection plan of the film coating machine for the preparation of UV glue by the barrier film. I hope it will be helpful to you. For the specific coating effect, please consult Beichao Technology to watch the demonstration video.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body