Hot melt adhesive coating film selection plan [coating machine case]

Foreword

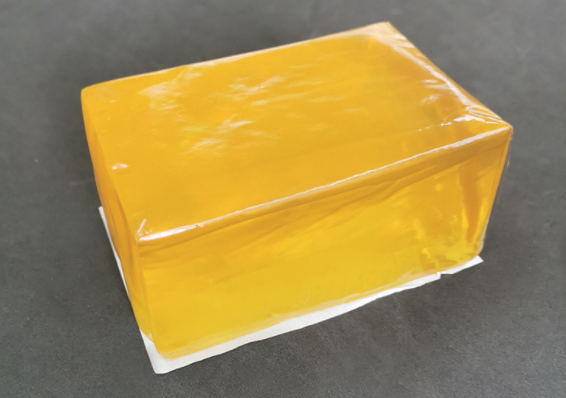

Hot melt adhesive is not only an adhesive, but also can be prepared on other substrates to make functional films or their protective effects, etc.

There are two situations for hot melt adhesive coating, one is to make films on films, paper, textile substrates, such as PET films; the other is to scratch coating on metal plates, etc. NBCHAO Technology recommends two solutions for the coating requirements of hot melt adhesives, one is a scraper heating vacuum adsorption coating machine, and the other is a scraper heating film coating machine.

Experimental requirements

The experimental requirements are relatively simple: hot melt adhesive coating; heating function is required.

Selection analysis

| substrate | Film or sheet metal | sample | Hot melt adhesive |

| film thickness | undecided | Other requirements | heating |

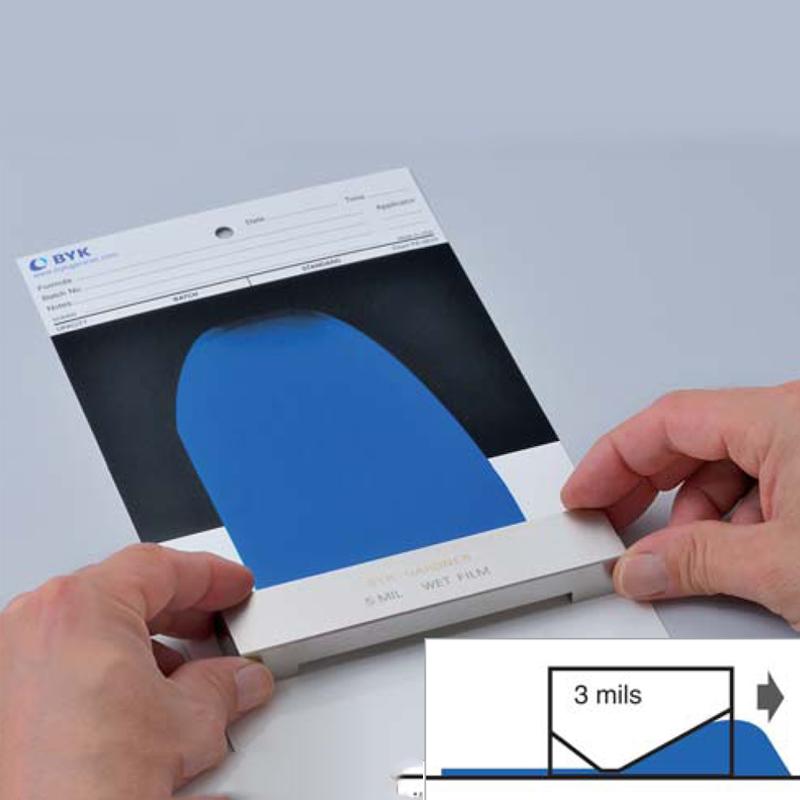

For samples such as hot melt adhesive, its more obvious property is that heating can maintain the molten state, and the cooling state is solid. If you want to apply and scrape the film, the sample must be liquid to operate normally, so the heating function is required, and the heating function of the general Film Applicator at 180 or 200 ℃ can basically meet the needs. In addition, hot melt adhesive is a kind of high-viscosity adhesive. If you use a wire rod, it is easy to cause scratches. You should choose a scraper Applicator, which can be a scraper Applicator with fixed film thickness, or an integrated scraper Film Applicator with adjustable film thickness (to meet more film thickness requirements).

固定膜厚的刮刀制备器

可调膜厚的一体式刮刀

Instrument parameters

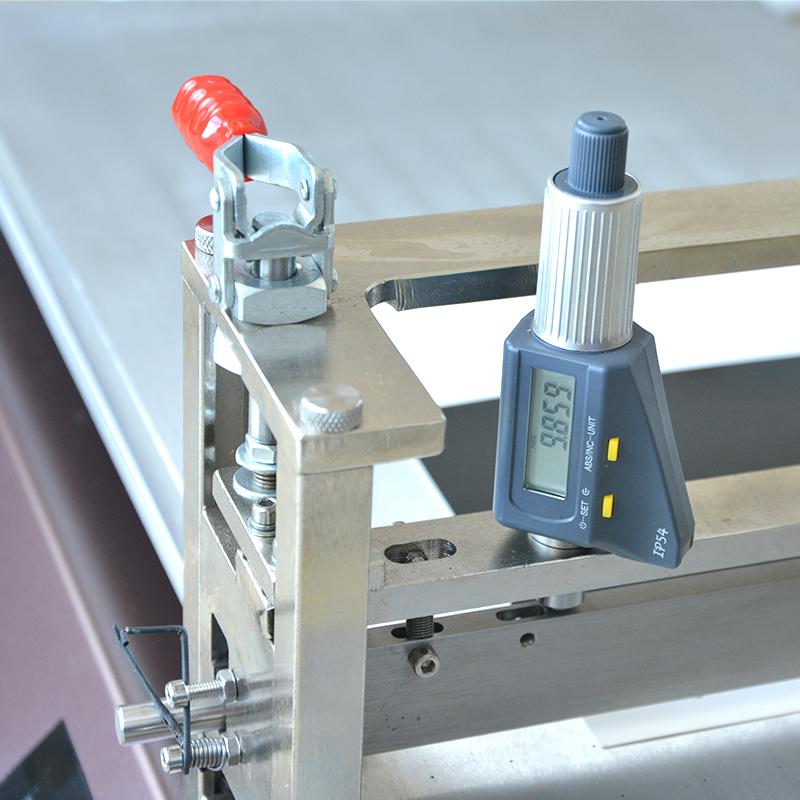

Let's take a look at the specific parameters of the two different coating machines for industry users to refer to and understand. Other specifications can be customized.

| TBJ-X5 Vacuum Adsorption Scraper Heating Coating Testing Machine |

| Specifications: coating accuracy ± 0.003MM, coating thickness range 0-10MM scraper can be lifted and lowered, coating rate 2~ 200mm/s, coating format 300 * 400mm, coating speed digital display, different speeds, vacuum adsorption size 300 * 400mm (can be customized), heating temperature range RT +~ 180 ℃, temperature accuracy ± 3 ℃, vacuum aperture Φ1.2mm, vacuum aperture 15 * 15mm, Vacuum Pump size 380 * 180 * 280mm, host power supply voltage 220V 50HZ, external size 630 * 410 * 520mm, net weight 65KG, Speed control stepless speed change, base plate material aluminum alloy, optional accessories liquid leakage tank, substrate fixing fixture, fine-tuning horizontal height support foot device, glass plate, silicone pad and weight (for applications with uneven thickness of coated substrates), Coating film width control baffle, customizable functional jet system device, UV solid inclusion device, automatic inking system | |

| TBJ-B3 Heating Scraper Coating Testing Machine |

| Specifications: coating accuracy ± 0.003mm, coating thickness range 0.2~ 10mm, coating rate 2~ 200mm/s, coating format 300 * 400mm, coating time digital display, different speeds, time accuracy control, heating temperature range RT +~ 200 ℃, temperature uniformity ± 3 ℃, scraper length 400MM material/stainless steel, host power supply 220V 50HZ 1700W, external size 690 * 410 * 520mm, net weight 65KG, speed control stepless speed change, bottom plate material aluminum alloy, optional accessories liquid leakage tank, substrate fixing Fixtures, trimming horizontal height support foot devices, glass plates, silicone pads and weights (for applications with uneven thickness of coated substrates), film width control baffles, customizable functional jet system devices, UV solid inclusion devices, automatic Inking system |

Coating effect

The following video is the experimental operation and effect of preparing hot melt adhesive on PET film.

The above is the selection plan of the laboratory coating machine for hot melt adhesives. I hope it will be helpful to you. Consult NBCHAO Technology for specific coating problems.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body