What surface treatment should be done for aluminum before salt spray test?

degreasing

During the salt spray test, if the aluminum material is not degreased or not degreased, it will directly affect the progress of the next process, so that the test data cannot be truly reflected. As an amphoteric metal, in order to prevent chemical attack during the cleaning process, when degreasing with alkaline detergents, its alkalinity needs to be low and corrosion inhibiting.

1. In theory, what characteristics should a good cleaning agent have?

All salts should be easily soluble in water, and have a certain stability and good flushing performance.

In order to maintain the stability of the cleaning agent and reduce the erosion of the base metal . The buffer needs to be inThe pH value of the working solution should be added within the range of 9~11.

In order to achieve a good degreasing effect, an emulsifier with good diffusion, wetting, penetration and emulsification should be selected.

It has anti-flocculation effect on small particles of dirt, making them dispersed in the solution.

In order to prevent the appearance of salt deposits on the metal surface, a cleaning agent with a softening effect is required .

2. Characteristics of acid degreasing agent

In the treatment, the acid degreasing agent has the effect of removing grease and conditioning the surface, but it has high requirements for equipment anticorrosion. In the test, sodium polyphosphate should be selected as the main component, and the low alkalinity alkaline degreasing liquid is composed of surfactants , corrosion inhibitors, complexing agents, etc., which can achieve good degreasing and cleaning effects.

Alkali etching, surface adjustment (Idemitsu)

Cast aluminum contains more impurities and is easy to oxidize. It is easy to oxidize and form green or white corrosion before coating , which will seriously affect the next process. In order to provide a good surface state for the next process, the oxide and corrosion products on the metal surface can be converted into a black or gray-black loose layer, and then the acidic surface adjustment solution is used to emit light. After cleaning, a bright, clean and uniform metal surface can be obtained .

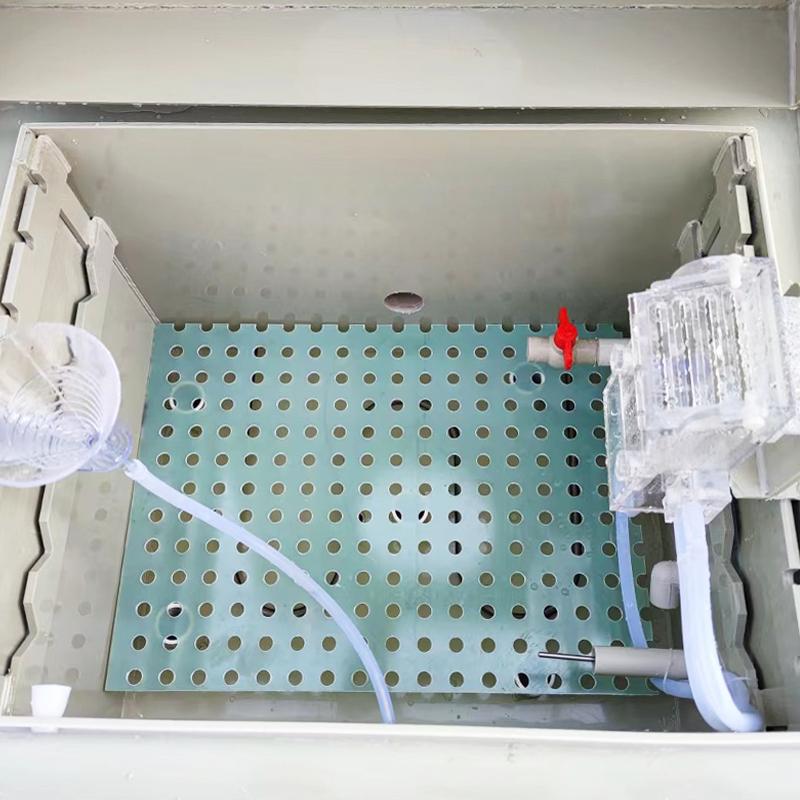

- 1Working Principle and Application Analysis of Ceiling Salt Spray Tester

- 2Principle, significance and method of salt spray test

- 3Salt spray test NSS, ACSS, CASS difference

- 4Different test methods and similarities and differences of salt spray test

- 5Salt Spray Tester in salt spray testing

- 6Hardware salt spray test method

- 7Cyclic corrosion test and its test procedures

- 8How Salt Spray Tests Improve the Quality of Metal Plating and Coatings

- 9How does the surface coating prevent corrosion?