How to extend the service life of rubber?

For all manufacturers in the rubber manufacturing industry, it is necessary to maintain the quality and durability of products that can be stored for a long time. Rubber is used in the manufacture of many types of products for household applications as well as industrial applications. Most countries obtain rubber from natural sources (i.e. plants). But the rubber that the manufacturer gets from the factory cannot be used directly for manufacturing purposes as it is very soft in nature and not suitable for the production of any kind of goods. In order for a natural product to be strictly useful, it goes through a vulcanization process.

What is vulcanization?

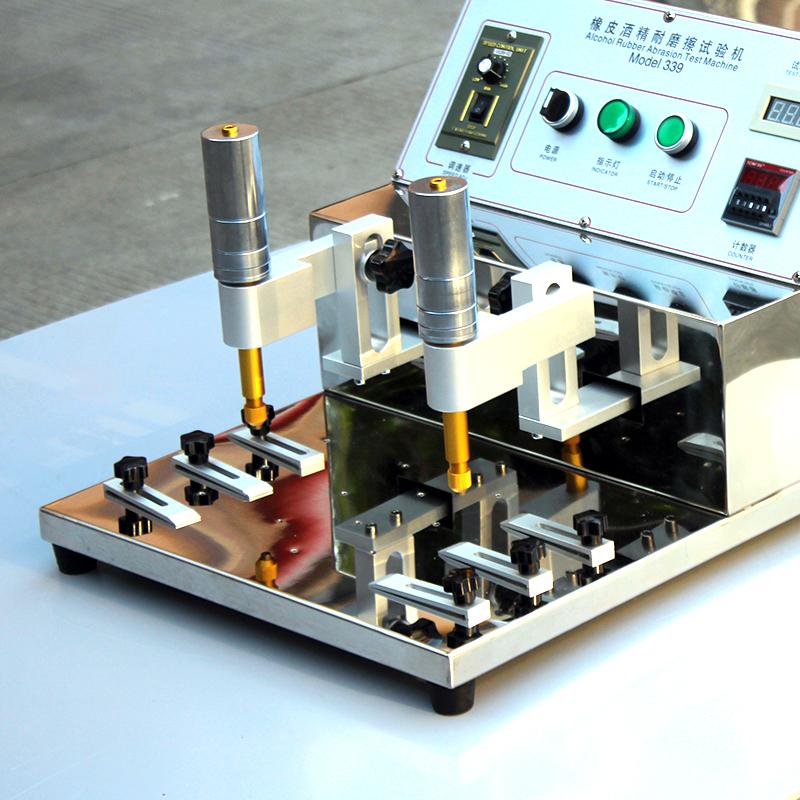

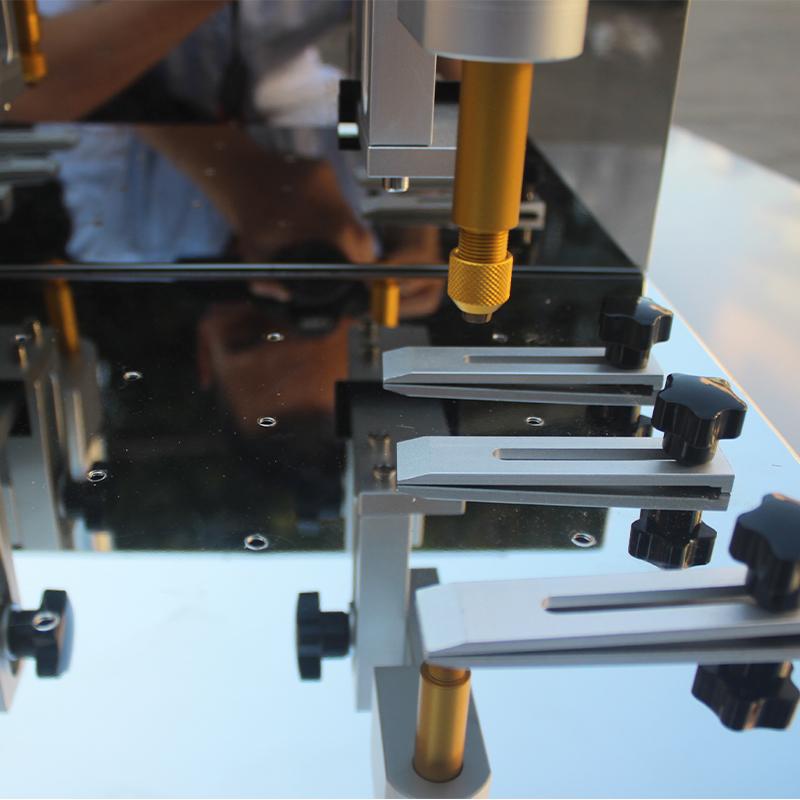

Vulcanization is the process of converting rubber into a solid form by changing its chemical composition and molecular structure. This is done by adding sufficient sulfur to the natural rubber during vulcanization . This process makes the rubber more difficult to use further. This thick rubber is used to make auto parts, tires, gaskets, other related components, etc. Since it is used in all critical applications, only good rubber needs to be used. A small defect in the quality of these products will directly harm people's lives and may cause fatal accidents. Rubber testing can be easily done with high-quality testing equipment.

The main factors that destroy the quality of rubber

The main factor that destroys the quality of rubber is wear. When rubbing rubber with abrasives during use, the quality of the rubber will be damaged, such as the quality of the sole, and the tire will be damaged during use. If the rubber is of good quality and wear-resistant, it can last longer. This can be effectively , which is used to test the quality of rubber.

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Demonstration of RCA wear-resistant tape machine

Air - 《南北潮》

- 7The principle, application, operation and selection of wear-resistant testing and wear-resistant testing machines

- 8What are the performance tests of vulcanized rubber?

- 9Briefly describe how different industries view product packaging