Do plastic materials need to measure melt viscosity?

Melt viscosity measurements are used to measure the ease with which molten pellets of thermoplastic polymers flow. This process helps correlate the value of the melt index MFI with the grade of the polymer so that the user can select the correct quality polymer. Test results are expressed in grams per ten minutes. Instruments used to measure the viscosity of plastic melts analyze raw materials to ensure product quality. Melt flow rate is a measure of molecular weight measured with high flow melt rate and is also a measure of a material's ability to melt under pressure. Melt flow rate MFR is inversely proportional to melt viscosity .

The melt flow index of a good plastic material needs to be high enough to form a molten polymer and low enough to maintain mechanical strength. The physical and chemical properties of polymers ensure the quality, reliability and durability of the material.

Selecting the Right Polymer Quality with Melt Viscosity Measurement

Melt Index MFI helps determine the weight, structure and viscosity of plastics. The lower the melt flow rate MFR, the molecular structure is complex, and if the plastic has a high melt index MFI, the molecular structure is simple. Measurement plays an important role for manufacturers and suppliers in the plastics industry. Melt viscosity measurements accurately determine the mass and viscosity of plastics. The plastic, PET and preform industries recommend testing machines to check the quality of plastic raw materials.

The importance of testing procedures in assessing material consistency or determining the degree of degradation during plastic molding cannot be overemphasized. Due to the low molecular weight, the degraded material had a high flow rate, which also indicated lower physical properties. In short, we can say that melt viscosity measurement is to identify or compare good and bad parts of plastics in a high quality testing instrument that provides accurate results in digital or computer format.

- 1Application of Melt index meter on plastic

- 2Glossmeter detects gloss on the surface of plastic products

- 3How to detect the opacity of rigid plastics?

- 4High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 5Why the Plastics Industry Does Melt Flow Rate Testing

- 6Knowledge of Melt Flow Index Tester

- 7How to judge the mechanical properties of plastics with melt flow rate meter?

- 8How it works to measure the flow properties of plastics and resins

- 95 Simple Steps to Operate a Melt Flow Rate Meter

-

-

-

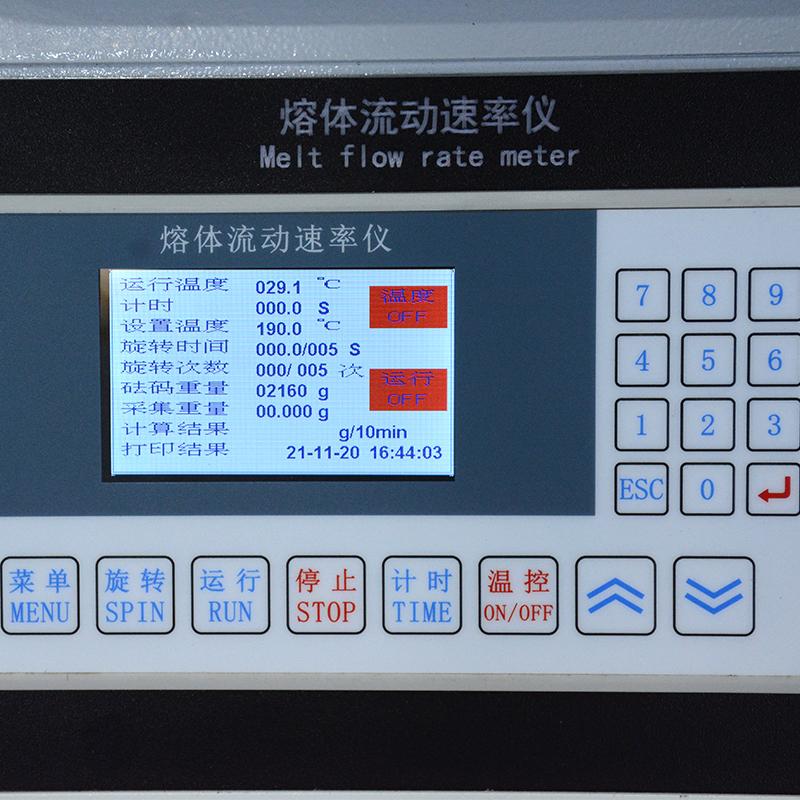

YOUKE YK3650 Melt Flow Indexer$ 964.00