How does muffle furnace affect rubber properties?

How to calculate the percentage of ash content in rubber?

Calculating the percentage of ash content in rubber is an important procedure in the rubber industry to evaluate the quality of rubber materials. Quality analysis is something any manufacturer needs to do before production.

Effect of Temperature on Rubber Properties

In order to assess the quality of a material, it is important to know its properties. Temperature plays an important role in determining the properties of rubber. Rubber hardens in cold weather and becomes pliable in hot weather. And, if we talk about the properties of rubber, ash is an important factor. It is intentionally added to it during the manufacturing process. A certain amount of ash is required to make it suitable for application. On the other hand, too much ash may lead to the volatile behavior of the rubber. A manufacturer who purchases rubber as a raw material knows what percentage of the sample he wants. But he cannot blindly trust suppliers. Therefore, the rubber was burnt into smoke to check the residual ash content remaining after heat treatment. This is all done in a controlled environment using a muffle furnace.

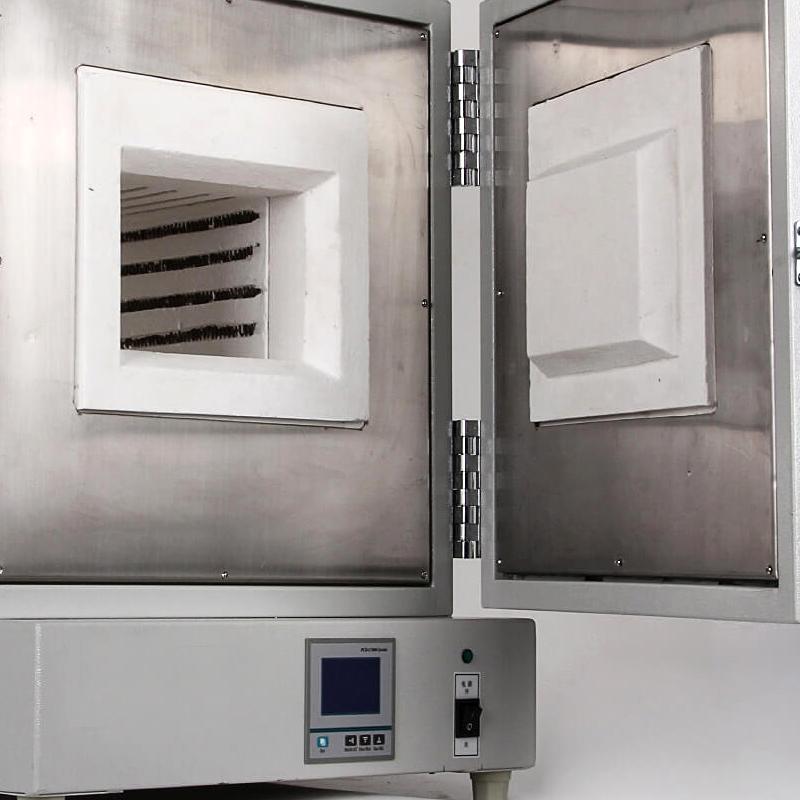

What is a muffle furnace?

It's more like an oven made of bricks, and the temperature range varies by model. Below this range, operators may see uneven test results. The machine has all protection features. It has double insulation to avoid any heat loss. It creates a nice and isolated environment for sample burning without any external disturbance . Muffle furnaces are suitable for different industries. The parts used in the manufacture are high quality parts which help to reduce the maintenance cost of the machine.

Steps

1. Connect the single-phase power supply to the muffle furnace.

2. Set the desired

3. Let the temperature rise to the set temperature and stabilize for a few minutes.

4. Heat the crucible at a specific temperature, such as 800°C, to remove moisture for 20-25 minutes, and then store the crucible in a cool place at room temperature.

5. Weigh the empty crucible on the balance. And measure the weight of the test sample. {Two weights (crucible and test sample) are measured separately}

6. Now weigh the test sample together with the crucible.

7. Put the crucible together with the sample into the muffle furnace. And set the desired temperature in the muffle for the specified time according to your sample specifications. After the contents have been ashed, allow the crucible to cool to room temperature. Reweigh the crucible with ashes from the scale to measure the weight.

- 1Principle and application of muffle furnace

- 2Introduction of working principle and application of muffle furnace

- 3Working principle and application analysis of muffle furnace

- 4Application of muffle furnace in Determination of Tobacco Ash

- 5How does a muffle furnace analyze the ash content in food?

- 6How to test the different properties of rubber?

- 7Determination of Ash and Pigment Base Ratio in Electrophoretic Coatings

- 84 factors to consider when choosing a furnace

- 9How does paper measure its ash content?