Matters needing attention in the test of melt flow index Tester

The melt flow index Tester is the mainstay of manufacturers in the plastics industry as it is the basic machine used to test the quality of plastic pellets, defining the quality of the material. Before starting a test procedure with a melt flow index Tester, certain things need to be considered so that the user can obtain accurate test results.

Machine leveling before testing

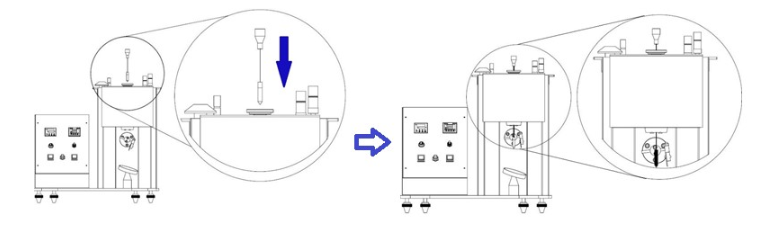

The machine should be leveled before starting the test procedure so that the user can obtain accurate test results.

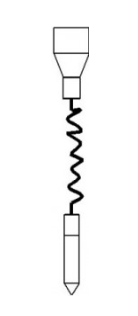

To check the leveling of the machine, use the plumb line supplied with the machine

Remove the orifice die from the machine and insert the plumb wire into the barrel.

Now check the verticality of the plumb line in relation to the ground.

If the plumb line is perfectly perpendicular to the ground, the machine is fully leveled.

If the plumb line deviates slightly from vertical, it means the machine needs to be leveled.

Level the machine by aligning the foot pedals.

This procedure can help you perform melt flow testing. After performing a test, it is necessary to clean the bucket firmly so that the next test can be performed with a different type of pellet to

Get accurate results. This will also help you maintain your equipment efficiently over the long term.

Clean bucket after test

After you have finished testing one material and have another to test, the barrel and orifice need to be properly cleaned for accurate test results.

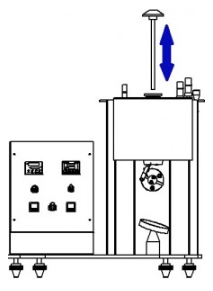

For barrel and bore cleaning, the temperature is raised above the melting point of the material being tested. The temperature should be raised by at least 10 C to 15 C. This will help loosen material stuck to the barrel walls or mold holes.

After raising the temperature, wait three to five minutes.

Now use the flat and threaded cleaning tool that came with your machine to clean the barrel and cavity of the cartridge.

Afterwards, the mold or orifice should be cleaned from the bottom of the bucket with an orifice cleaning tool.

After cleaning is complete, another material can be tested.

This process will help you maintain your instrument over time and help you test different types of particles time and time again with accurate results. have