Preparation of lithium battery slurry on aluminum foil and copper foil [Case of experimental coating machine]

foreword

Lithium battery is currently the key development direction of GJ. Therefore, in recent years, there has been an upsurge of research on high-performance lithium batteries. Many technical researchers are studying lithium batteries that are more environmentally friendly, safer, higher capacity, and longer life.

Potassium ion battery refers to a secondary battery system that uses two different potassium intercalation compounds that can reversibly insert and extract potassium ions as active materials for the positive and negative electrodes of the battery, respectively. The carp ion battery is composed of electrolyte, positive and negative electrodes, diaphragm and shell components. Among them, the electrode material is a key factor affecting the performance of potassium-ion batteries, and its physical and chemical properties directly affect the overall performance level of carp-ion batteries. Electrolyte is also an important factor in determining the electrochemical performance of potassium ion batteries.

Here are a few research papers on lithium batteries:

"Study on Preparation and Electrochemical Performance of Silver Nanowire-Silicon Carbon Composite Anode Material"

"Preparation and Electrochemical Properties of New Carbon Materials and Their Composite Materials"

"Preparation of carbon-based nanocomposites and their application in lithium-ion battery anodes"

"Basic Research on the Application of Graphene as Lithium-ion Battery Anode Materials"

"Research on Preparation of Lithium Battery Separator by Modification of Cellulose in Sodium Hydroxide-Urea System"

"Preparation and Properties of Phosphate Cathode Materials"

"Preparation of polymer-ceramic composite separator and its battery performance"

"Preparation and Electrochemical Properties of Nano-carbon Fiber Matrix Composites for Lithium-ion Battery Negative Electrode"

This issue is a case selection analysis of NBCHAO Technology's demand for a lithium battery coating film and the effect of a coating machine preparing slurry on aluminum foil.

User needs

User's needs: For lithium batteries, proofing is made on copper foil and aluminum foil, and the thickness of scraping is 2-100 microns.

| Substrate | copper foil, aluminum foil | sample | slurry |

| film thickness | 2~100 microns | other requirements | none |

How to choose a film coating machine?

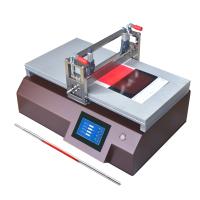

Technical analysis: The characteristics of aluminum foil and copper foil are soft, brittle and thin, similar to thin films, so vacuum adsorption must be used to keep them flat. In addition, if the thickness of the wet film is uncertain but wants to make an ultra-thin film, it is generally recommended to use a combination of wire rod + adjustable scraper to ensure the accuracy of the film and meet the preparation requirements of different film thicknesses. . Therefore, Beichao Technology recommends wire rod + scraper + vacuum adsorption three-in-one small coating machine.

Let's take a look at the specific parameters of the film coating machine for reference by industry users. Other specifications can be customized.

Experimental coating film effect video

The above is the application plan of the coating machine for preparing lithium battery slurry on aluminum foil and copper foil. I hope it will be helpful to you .

Lithium battery related standards

SJ/T 11483-2014 "Electrolytic Copper Foil for Lithium-ion Batteries"

GB/T 30836-2014 "Lithium titanate and its carbon composite anode materials for lithium ion batteries"

GB/Z 18333.1-2001 "Lithium-ion batteries for electric road vehicles"

GB/T 36363-2018 "Polyolefin Separators for Lithium-ion Batteries"

QC/T 743-2006 "Lithium-ion batteries for electric vehicles"

SJ 20941-2005 "General Specifications for Lithium-ion Batteries"

GB/T 30835-2014 "Carbon Composite Lithium Iron Phosphate Cathode Material for Lithium-ion Batteries"

For more battery standards, go to: www.nbchao.com/s/

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body

![Preparation of lithium battery slurry on aluminum foil and copper foil [Experimental coating machine case] with picture 1](http://img.nbchao.com/upload/editor/image/20230209/1675909631176042459.jpg)