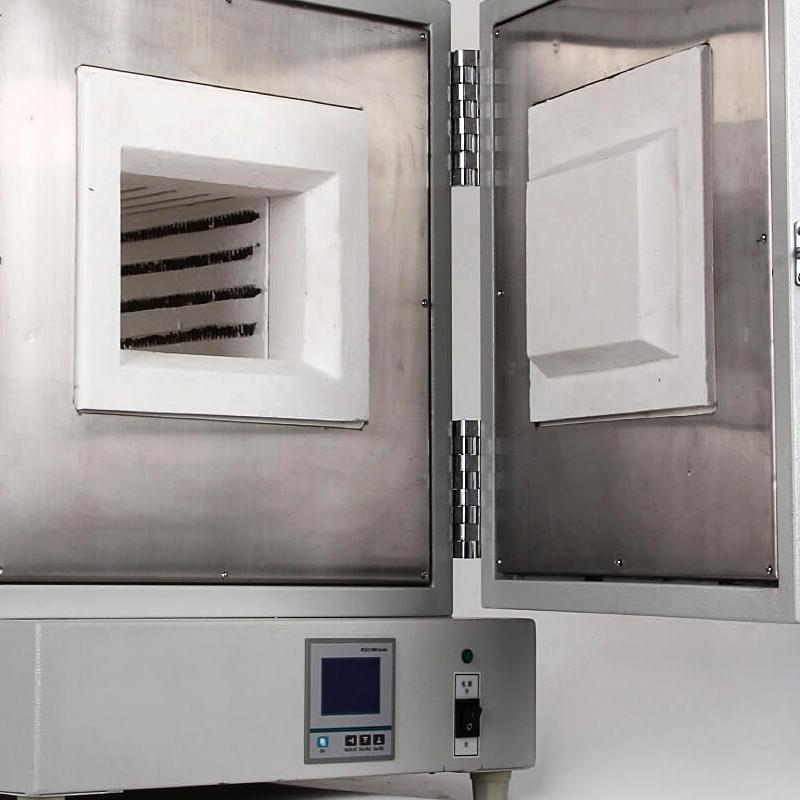

How does a muffle furnace analyze the ash content in food?

When the organic matter of the material is burned, what is left is ash. It is an inorganic substance present in any material. If any material is heated to the point of combustion in the presence of an oxidizing agent, only ash will remain. In order to assess the quality of a material, it is important to assess the presence of inorganic components . Different procedures are defined to measure the ash content in food products and they are:

wet ashing

dry ash

low temperature ashing

The test method is selected according to the application of the material, the requirements of the sample, and the specification of the sample. These testing procedures also help in the analysis of stored

minerals because they are easy to distinguish.

In the food industry, to determine the quality of food, different tests are performed. Ash testing is catching up with trends these days because it tells a lot about quality. Minerals present in the material can also be assessed by this test. According to the regulator , ash content up to 5% is acceptable and not only that, but also helps determine the age of the food.

How to prepare samples?

For ash testing, the importance of sample preparation cannot be overstated. Food samples need to be in powder form. Any moisture content dries out first, which causes watering during heating. Fatty food samples retain moisture as they dry, preventing splatter. Another major concern is sample contamination due to the surrounding environment or the container used to hold the sample. Samples need to weigh between 1 and 10 grams.

Different methods of testing with a muffle furnace

dry ashing

During this process, a muffle furnace is used to burn the sample. The chamber temperature was maintained at about 600°C. At this temperature, water evaporates from the sample and the remaining contents burn off. During this process, most minerals are converted to phosphates, sulfates and oxides. Due to the presence of some volatile substances in the sample, the test results may not be accurate. This is why other test methods are preferred when materials such as lead, mercury and iron are present in the sample. By taking advantage of technological advancements, smart analytical instruments have been introduced in the market that do not require sample handling prior to testing. They are equipped with decision-making circuits that first dry the moisture and then turn it into ash for analysis, using a very high temperature range.

wet ashing

This technique for determining the ash content in food samples is relatively quicker than other techniques. Time period may vary from 10 minutes

to several hours. During this process, the temperature range was set to 350°C.

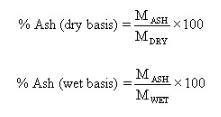

The weight difference before and after the test is the percentage of ash content:

MASH = mass of ash sample,

MDRY = Refers to the mass of the dry sample.

MWET = Refers to the mass of the wet sample.

- 1Principle and application of muffle furnace

- 2Introduction of working principle and application of muffle furnace

- 3Working principle and application analysis of muffle furnace

- 4Application of muffle furnace in Determination of Tobacco Ash

- 5Determination of viscosity of food by Rotational Viscometer

- 6How does muffle furnace affect rubber properties?

- 7How to test the different properties of rubber?

- 8Determination of Ash and Pigment Base Ratio in Electrophoretic Coatings

- 94 factors to consider when choosing a furnace