How to choose the correct type of ink viscometer?

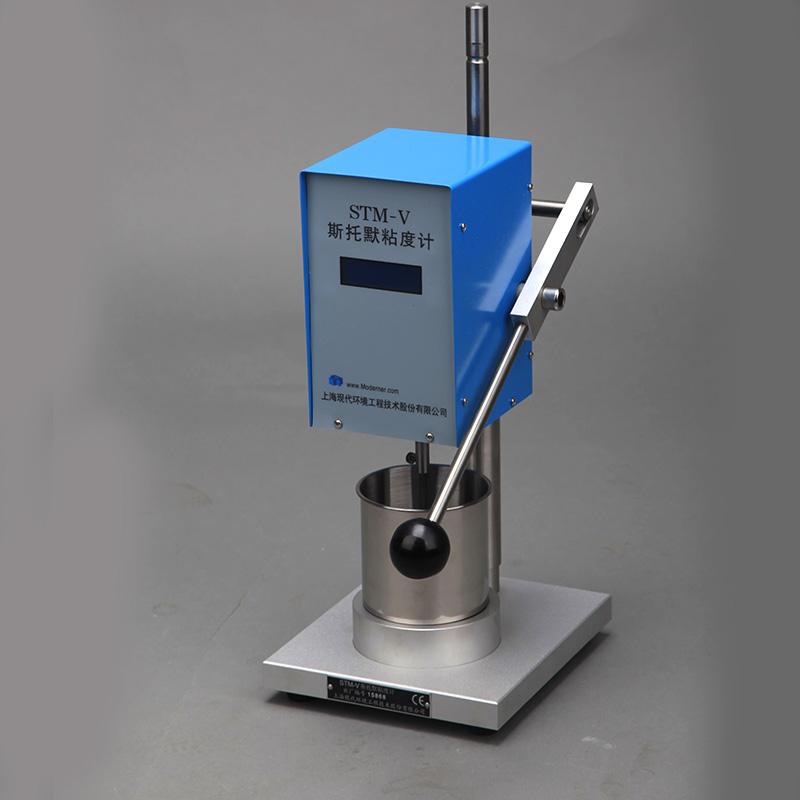

Ink viscometer is an instrument used to measure the viscosity of ink, paint, resin and other materials. In ink printing and coating production process, viscosity is a key parameter to control product quality. Choosing the right ink viscometer can help producers ensure the accuracy and quality of their products.

The following is a detailed introduction to the selection points and precautions of ink viscometer:

Measuring range: To choose an ink viscosity meter, you need to choose an appropriate measuring range according to actual needs. Generally speaking, the wider the measurement range, the more types of materials are applicable, but the price will rise accordingly.

Accuracy: The higher the accuracy of the ink viscometer, the more accurate the measurement results. In general, high-precision ink viscometers are suitable for applications that require extremely high precision, such as medicine and food.

Measuring method: The ink viscometer can adopt various measuring methods such as rotary type, titration type and compression type. Among them, the rotary measurement method is suitable for liquids with higher viscosity, while the titration and compression methods are suitable for liquids with lower viscosity.

Temperature control: temperature is an important factor affecting ink viscosity. Therefore, some ink viscometers are equipped with a temperature control device, which can heat the sample to a certain temperature before measurement to ensure the accuracy of the measurement results.

Reusability: When conducting a large number of tests, you can consider choosing a reusable ink viscometer to improve test efficiency and save costs.

Price: The price of ink viscometer varies with brand, model, accuracy, measurement range and other factors. When choosing, you need to weigh and choose according to your own needs and economic strength.

Precautions

Pay attention to safety in operation: when using the ink viscosity meter, it is necessary to pay attention to safe operation to prevent the sample from splashing or contacting the skin and eyes.

Maintenance: Regularly maintain the ink viscometer, clean the instrument, replace parts, etc., to ensure the normal use of the instrument and the accuracy of the test.

Calibration: Ink viscometers need to be calibrated periodically to ensure the accuracy and consistency of test results.

Applicable materials: different types of ink viscometers.

- 1Viscosity of polypropylene (PP) amide measured by NDJ Viscometer

- 2Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 3Application of Rotational Viscometer in juice viscosity test

- 4Working Principle, Classification and Application of Capillary Viscometer

- 5Principle, Characteristics and Application of Dial Viscometer

- 6Basic Principle and Application of Ceramic Viscometer

- 7Principle, Characteristics and Application of QND Viscometer

- 8Determination of epoxy resin viscosity by Rotational Viscometer

- 9Rotational viscometer selection suggestions