Coated steel coating mass testing standards

The quality inspection of color-coated plates is mainly the inspection of coating pretreatment and coating performance. The pretreatment inspection of coating includes two aspects of degreasing degree and chemical conversion coating. The detection of the coating includes two aspects: the mechanical properties of the coating (such as adhesion, flexibility, impact strength, hardness, gloss, etc.) and the special properties with protective functions (such as weather resistance, acid and alkali resistance and oil resistance). Among them, mechanical properties are the basic routine properties that need to be tested in the quality inspection of coatings. The properties of special beads with protective functions can be selectively tested according to different use requirements. The country has relevant testing standards for the testing of the above commercial properties :

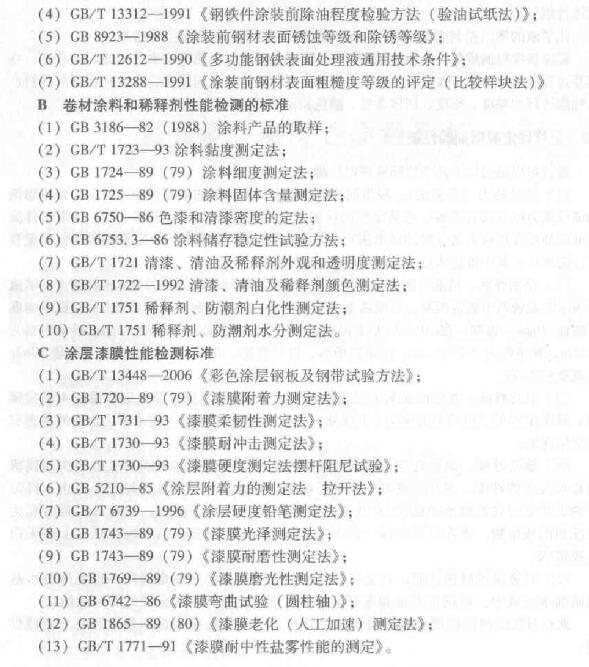

A Coating pretreatment performance testing standard

(1) GB/T 11376—1997 "Phosphate conversion coating of metals";

(2) CB/T 17460-1998 "Chemical Conversion Coatings Rinse and Non-Rinse Fryate Conversion Coatings on Aluminum and Molybdenum Alloys";

(3) GB/T9792-l983 "Gravimetric method for measuring the mass of upper and lower film layers per unit area of conversion film on metal materials";

In addition there are such as: GB/T 13312-1991, GB 8923-1988, GB/T 12612-1990, GB/T 13288-1991

B Standards for Coil Coating and Thinner Performance Checks

Such as paint viscosity measurement, fineness measurement, solid content measurement, density, stability, etc. (related instruments: specific gravity cup, Fineness Meter, etc.)

C Coating film performance standard

Such as impact resistance, flexibility, pencil hardness, etc. of color-coated plates. (Related instruments: such as impact Tester)

Please refer to the figure below for these standards:

- 1Key performance of coil coatings and detection method

- 2Coil coatings aging test

- 3Coating appearance quality and coating inspection

- 4Standards for quality inspection of color-coated boards

- 5Color coated board back paint

- 6Coated steel coatings adhesion performance

范纯, 张家琪, 姜宝宇 宝钢股份公司 制造管理部 - 《钢铁研究》

- 7Coiling performance testing How is the current sampling?

- 8Coated steel coating mass control and use equipment

- 9Coated steel film thickness control