Selection skills of laboratory small automatic coating machine

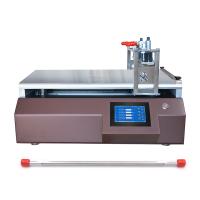

The laboratory small automatic coating machine is an instrument and equipment used to coat the surface of samples. It can perform various coating experiments in the laboratory, such as printing, spraying, coating, ink, etc. The following is a detailed introduction to the selection points and precautions:

select points

Coating width and length: It is necessary to select the appropriate coating width and length according to the experimental requirements, usually the coating width is between 10mm-300mm.

Coating speed: Different coating speeds can obtain different coating quality, and different coating speeds need to be selected according to experimental requirements.

Coating thickness adjustment: Some experiments need to obtain a specific coating thickness, and it is necessary to select an automatic coating machine that can adjust the coating thickness.

Control mode: There are two control modes of the coating machine, manual and automatic, and the appropriate control mode should be selected according to the experimental requirements.

Accuracy: The coating accuracy of the automatic coating machine is usually between 1-2 μm, and it is necessary to select an automatic coating machine with higher precision requirements according to the experimental requirements.

Equipment brand and after-sales service: Choosing equipment with a familiar brand can further guarantee the quality of the equipment and the reliability of after-sales service.

Precautions

Before use, it is necessary to check whether the equipment is normal, whether the coating blade is sharp, and whether the coating wheel is flat.

During operation, it is necessary to select the coating width, coating speed and coating thickness according to the experimental requirements, and adjust them as needed.

During operation, it is necessary to avoid splashing of the coating liquid to avoid pollution and damage to the equipment and experimental environment.

After the operation, the equipment needs to be cleaned in time to keep the equipment clean and dry to avoid the accumulation of dirt and rust.

Regular equipment maintenance and maintenance to avoid equipment failure and affect the progress of the experiment.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative