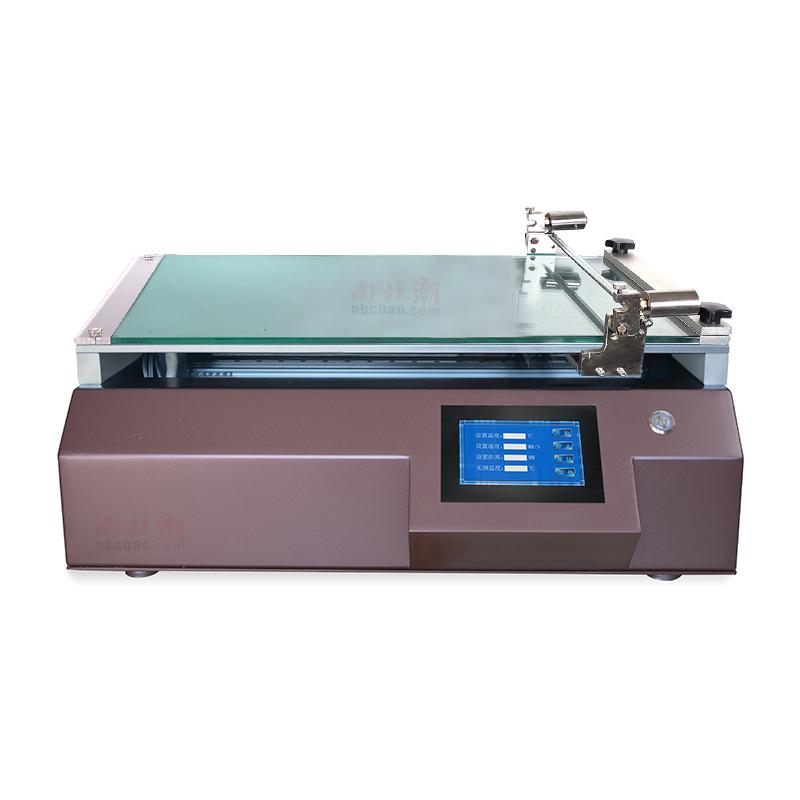

Laboratory automatic coating machine selection considerations

Laboratory automatic coating machine is an instrument used to automatically coat various coatings or samples on different substrates. It is widely used in scientific research, quality inspection, manufacturing and other fields. The following are the selection points and precautions for this device.

select points

Coating materials and substrates: It is necessary to select the corresponding automatic coating machine according to the actual needs. For example, the viscosity and fluidity of the coating materials should be considered when purchasing, as well as the size and surface characteristics of the substrate. .

Coating width: Coating width is an important factor in choosing an automatic coating machine, which needs to be selected according to actual needs.

Coating speed: Coating speed is an important parameter of automatic coating machine, which usually needs to be selected according to actual needs.

Operation mode: There are two operation modes of the automatic coating machine, manual and automatic, which need to be selected according to actual needs.

Accuracy and repeatability: When choosing an automatic coating machine, it is necessary to consider its coating accuracy and repeatability. Usually, it is necessary to choose a model with higher precision and better repeatability.

Precautions

The installation and commissioning of the equipment requires professionals to ensure the normal operation of the equipment.

When using an automatic coating machine, safety precautions need to be taken, such as avoiding the coating material from contacting the skin and eyes.

It is necessary to operate according to the operation manual to avoid equipment damage or accidents caused by improper operation.

Regularly maintain and maintain the equipment, such as cleaning equipment, replacing wearing parts, etc.

When choosing equipment, you need to consider the brand, after-sales service, price and other factors of the equipment in order to obtain a better experience and after-sales service.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative