Single angle gloss meter selection method

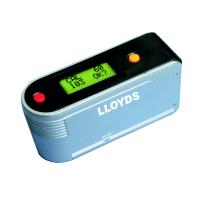

A single angle gloss meter is an instrument commonly used to measure the surface gloss of materials. It is suitable for surface quality control of various materials, such as coatings, plastics, ceramics, metals, paper, wood, etc. The following will introduce the selection points and precautions of single angle gloss meter.

select points

Measurement angle: Single-angle gloss meters can generally choose different measurement angles, such as 20 degrees, 45 degrees, 60 degrees, etc. The selection of measurement angles should be based on the material of the sample to be tested and the application scene.

Measuring range: Different single-angle Glossmeters have different measuring ranges, and the appropriate instrument should be selected according to actual needs.

Accuracy: Accuracy is an important index to evaluate the quality of single-angle gloss meter, and the appropriate accuracy should be selected according to the needs.

Repeatability: Repeatability is also an important indicator for evaluating the performance of single-angle Glossmeters. It refers to the consistency of measurement results when the same sample is measured multiple times under the same conditions. The better the repeatability, the more reliable the measurement results.

Other functions: such as data storage, data transmission, automatic calibration and other functions, choose whether you need it according to actual needs.

Precautions

The surface of the sample should be smooth and free of scratches, and the thickness of the sample should be consistent to ensure the accuracy of the measurement results.

Preheating should be carried out before use to ensure the stability of the instrument.

The instrument should be kept dry and clean to avoid the influence of dust and other impurities on the measurement results.

Zero calibration and standard calibration should be performed before measurement to ensure the accuracy of measurement results.

When measuring, the light source should be prevented from directly shining on the probe, so as not to affect the measurement results.

The measurement results should be averaged for multiple measurements to improve the reliability of the measurement results.

The instrument should be cleaned and maintained after use to prolong the life of the instrument.