Application, Operation Points and Selection Considerations of Laboratory Coating Machine

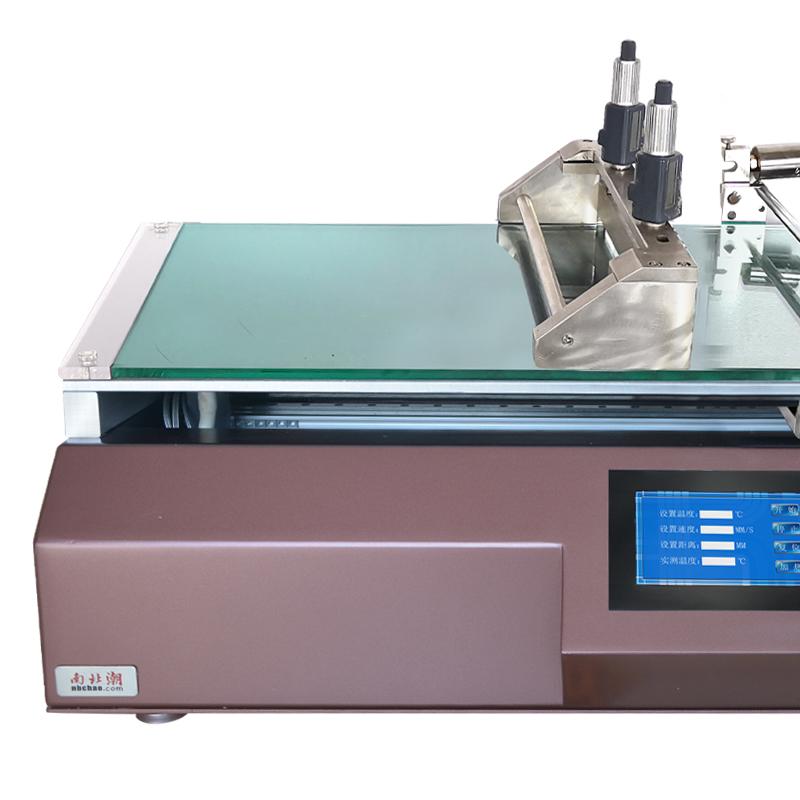

The experimental Film Applicator is a commonly used equipment in the laboratory, which is used to prepare a uniform thin film coating on the surface of the sample. The Film Applicator usually uses spin coating or blade coating to uniformly coat the solution or dispersion on the surface of the sample, and then forms a uniform film by drying or curing.

Application field

Experimental Film Applicators are usually used to prepare various functional films, such as photoelectric films, anti-corrosion films, antibacterial films, breathable films, etc. In the fields of material science, chemistry, biology and medicine, coating technology is widely used in various experiments and research projects.

Metal thin film: The coating machine can uniformly deposit metal materials on the surface of the substrate by techniques such as physical vapor deposition (PVD) or chemical vapor deposition (CVD).

Ceramic coating: Using techniques such as sol-gel method and radio frequency magnetron sputtering (RF sputtering), ceramic materials can be deposited on the surface of the substrate.

Polymer film: The polymer coating can be evenly coated on the surface of the substrate by using solution spin coating, blade coating, roller coating and other techniques.

Biomaterials: biomedical materials, such as implant materials and repair materials, can be prepared by coating films of biodegradable polymers, bioglass and other materials.

Graphene film: The film coating machine can use chemical vapor deposition to evenly deposit graphene on the surface of the substrate.

Optical thin films: Transparent or semi-transparent optical thin films, such as filter films and reflective films, can be prepared by using techniques such as physical vapor deposition or magnetron sputtering.

The coating machine can prepare various materials, including coating inks, ceramics, polymers, biomaterials, graphene, optical materials, etc. The exact coating technique used depends on the nature of the material and the needs of the application.

Operating points

1. Substrate surface treatment: Before coating the film, the substrate needs to be properly surface treated to ensure that the coating can be evenly attached to the substrate surface, and has good adhesion and durability. Surface treatment methods may include cleaning, decontamination, polishing, etching, and the like.

2. Coating selection: When selecting coatings, its physical and chemical properties, solubility, viscosity, solid content and other factors need to be considered, and appropriate coatings should be selected according to material requirements.

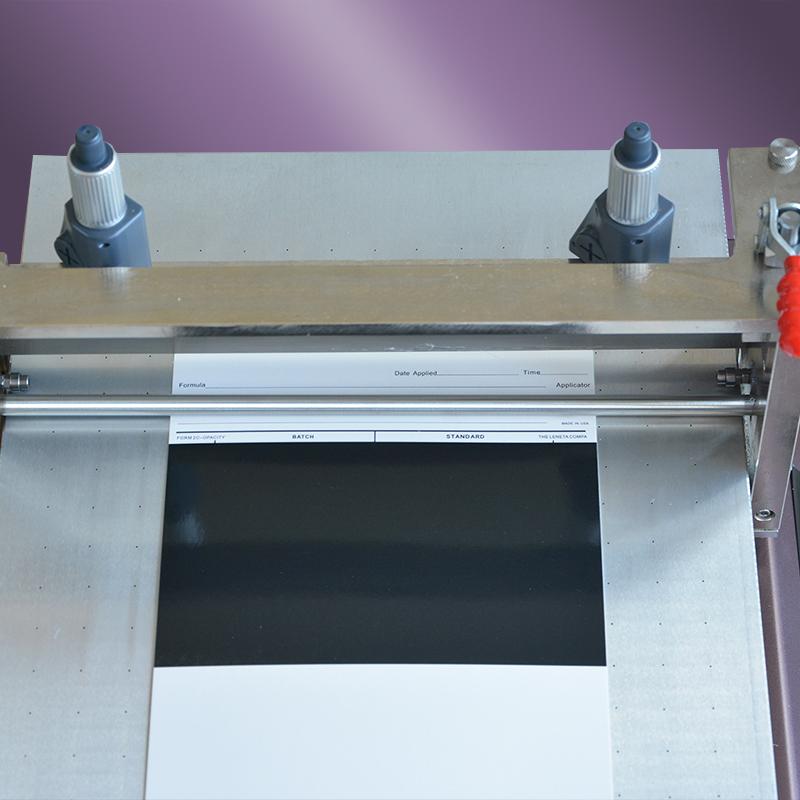

3. Coating thickness control: Coating thickness is one of the important factors affecting coating performance. During the coating process, the thickness of the coating needs to be controlled, which can usually be achieved by controlling the speed of the wire rod or scraper, the film thickness of the film maker, and the viscosity of the coating.

4. Coating uniformity control: Coating uniformity also has a great influence on coating performance. During the coating process, it is necessary to maintain the uniform distribution of the coating and ensure that there are no obvious defects and bubbles on the coating surface.

5. Coating machine parameter setting: The parameter setting of the coating machine is also very critical. It is necessary to reasonably set the temperature, speed, vacuum degree and other parameters of the coating machine according to different coatings and substrate types to ensure the quality and quality of the coating. performance.

6. Safe operation: Pay attention to safety issues during the operation of the film coating machine, especially some materials are toxic, such as wearing protective glasses, gloves and breathing masks, etc., to avoid harm to personnel and the environment.

Selection considerations

Application field: First of all, it is necessary to determine the application field of the laboratory film coating machine, such as cell culture in the biomedical field, or thin film preparation in the optical field. Different fields of application require different laboratory coaters.

Coating material: The choice of laboratory coating machine also needs to consider the coating material, such as organic matter, inorganic matter, metal, etc. Different coating materials require different coating machines.

Coating technology: The coating technology of the laboratory coating machine includes sputtering, ion beam sputtering, chemical vapor deposition, physical vapor deposition, etc. When selecting a laboratory Film Applicator, it is necessary to consider the film coating technology required and whether the Film Applicator supports that technology.

Coating film size: The coating film size of the laboratory film coating machine is also an important factor, and the appropriate film coating machine needs to be selected according to the experimental needs.

Operation and Maintenance: The difficulty of operation and maintenance, as well as the training and maintenance support required, also need to be considered when selecting a laboratory Film Applicator.

To sum up, the selection of a laboratory coating machine needs to comprehensively consider factors such as application field, coating material, coating technology, coating size, operation and maintenance, in order to select a coating machine suitable for the experimental needs.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research