Application of Coating Machine in Perovskite Coating

overview

Perovskite coating is a technique for applying perovskite materials to solar cells. Perovskite is a mineral with crystal structure ABX3, where A, B, and X represent different atoms. In perovskite solar cells, perovskite materials are used to absorb light and convert it into electricity.

Coating is the application of the perovskite material in the form of a solution on the surface of the solar cell. This method is simpler and more economical than other methods for preparing perovskite solar cells, because the coating can be performed at lower temperatures and does not require high-temperature treatment.

The coating process includes the steps of preparing perovskite solution, coating the solution on the electrode, drying and annealing. During the coating process, some adjustments can be made to the solution to improve the performance of the solar cell, such as adding different additives, adjusting the coating speed, etc.

The advantages of perovskite coating technology include simple preparation process, low production cost, and large amount of prepared materials. Therefore, it has become one of the important technologies for preparing efficient solar cells.

Steps

The steps for coating perovskite using a laboratory coater are as follows:

Prepare the substrate: First, prepare the substrate to be coated with perovskite. The substrate should be flat, clean and dust-free, and the surface should be treated to enhance the adhesion of the perovskite to the substrate.

Preparation of perovskite solution: To prepare perovskite solution, a mixed solution of lead orthonitrate and lead methylamine solution is usually used. According to specific experimental requirements, some other additives can also be added, such as surfactants, solvents, stabilizers, etc.

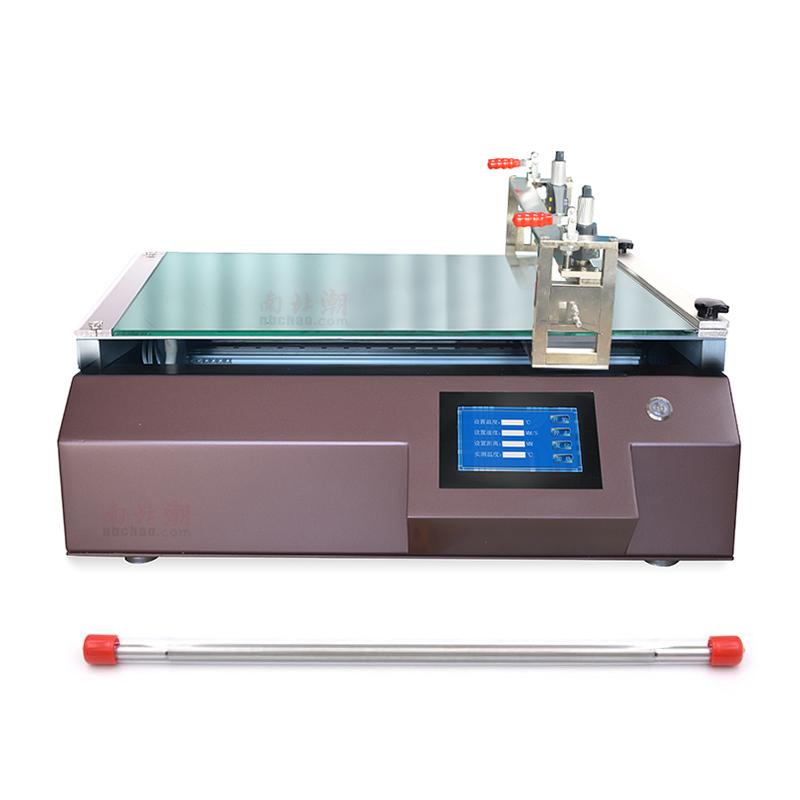

Adjust the coating parameters: before coating the coating machine, it is necessary to adjust the coating parameters, including coating speed, rotation speed, interval time and other parameters, in order to obtain better coating effect.

Coating: Place the substrate on the clamping device of the coating machine, pour the perovskite solution into the coater, and start the coater for coating. When coating, uniform coating thickness should be maintained.

Drying: After the coating is completed, put the substrate into an oven for drying. The drying temperature and time need to be adjusted according to specific experimental needs.

Annealing: After drying, the substrate is placed in a furnace for annealing. The annealing temperature and time also need to be adjusted according to specific experimental requirements.

Test: After the annealing process is completed, the substrate is taken out for testing, including measuring parameters such as current, voltage, and efficiency of the perovskite solar cell.

NBCHAO reminds you: Coating perovskite with a film coating machine requires certain operating skills and experimental experience, especially in the process of adjusting coating parameters and processing the substrate surface to avoid affecting the performance of perovskite solar cells .

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body