Simple Selection Method of Magnetic Induction Coating Thickness Gauge

The magnetic induction coating Thickness Gauge is an instrument for measuring the thickness of the coating, and the thickness of the coating is determined by measuring the magnetic induction intensity. The following are the selection points and precautions:

select points

Measuring range: The range of the required measuring task should be considered when choosing. Generally, the measuring range of the magnetic induction coating Thickness Gauge should be between 0-2000um.

Accuracy: Accuracy is an important indicator that affects the accuracy of measurement results. Therefore, when selecting a magnetic induction coating Thickness Gauge, an instrument with high precision should be selected.

Display mode: digital display mode is more common, and some advanced instruments also have LCD screen and backlight function.

Data storage: Some advanced magnetic induction coating Thickness Gauges can store multiple sets of data, and can transmit data to a computer or mobile device via USB or Bluetooth.

Operation mode: When choosing a magnetic induction coating Thickness Gauge, you should consider whether its operation mode is simple and easy to understand, and whether it needs special training to master it.

Probe type: The probe type of the magnetic induction coating Thickness Gauge is divided into two types: single-needle probe and double-needle probe. When selecting, the appropriate probe type should be selected according to the characteristics of the measurement object.

Standards: When selecting, you should consider whether the instrument complies with the corresponding standards and specifications to ensure the accuracy and reliability of the measurement results.

Precautions

Calibration: Calibration is required before using the magnetic induction coating Thickness Gauge. The purpose of calibration is to ensure the accuracy and reliability of the instrument.

Cleaning: Before measuring, the instrument should be cleaned to avoid contamination such as dust or grease from affecting the measurement results.

Measurement location: When measuring, a representative measurement location should be selected to ensure the accuracy of the measurement results.

Measurement angle: When measuring, the magnetic induction coating Thickness Gauge should be measured perpendicular to the surface of the measured object to avoid measurement errors caused by incorrect angles.

Maintenance: During use, attention should also be paid to the maintenance and maintenance of the magnetic induction coating Thickness Gauge, and the probe should be cleaned and replaced in time

- 1General guidelines for the use of platings

- 2Coating platings Thickness Gauge FAQ and its solution

- 3Tide Review: McCourt Coating Thickness Gauge MikroTest G 6

- 4Yuwen Automobile Coating Thickness Gauge Function Video Introduction

- 5Yuwen EC-777 Automobile Coating Thickness Gauge Beauty Appreciation

- 6QNIX Nix 4200 Magnetic Induction Coating Thickness Gauge Real Photo Appreciation

- 7QNIX 8500 Coating Thickness Gauge Real Photo Appreciation

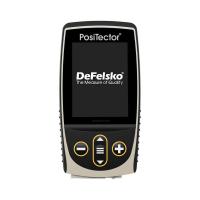

- 8Defelsko Positector 6000 NRS1 Coating Thickness Gauge Beauty Appreciation

- 9Defelsko PosiTest mechanical coating Thickness Gauge evaluation [with high definition real picture]