Several Selection Factors of Dry Film Thickness Gauge

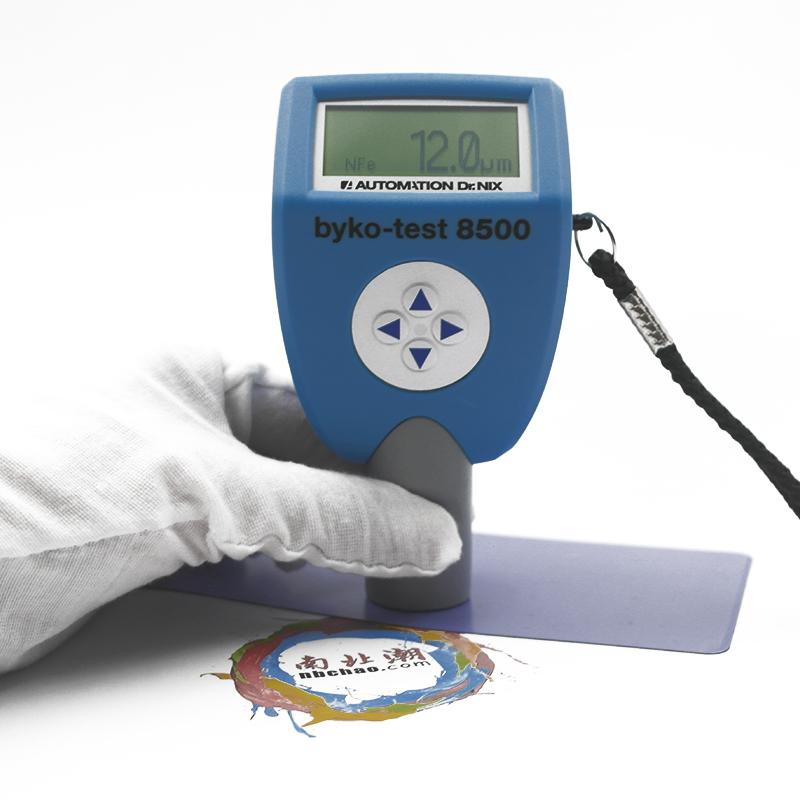

The dry Film Thickness Gauge is an instrument used to measure the dry film thickness of the coating or paint surface. The selection points and precautions are as follows:

select points

Measuring range: Choose a measuring range that can cover the range of dry film thickness that needs to be measured. Generally speaking, you should choose a measuring instrument that is wider than the thickness range that needs to be measured in order to better adapt to practical applications.

Measurement accuracy: Measurement accuracy is an important indicator for choosing a dry Film Thickness Gauge. An instrument with high precision and small error should be selected to ensure the accuracy and reliability of the measurement results.

Probe shape: Select different shapes of probes according to the shape and surface state of the coating to ensure the accuracy and precision of the measurement.

Display method: There are two methods of digital display and graphic display. The digital display method is usually more accurate than the graphic display method, but for non-professionals, the graphic display method is easier to understand.

Software function: Choose an instrument with data storage, export, analysis and other functions to manage and analyze measurement data more conveniently.

Precautions

Maintenance and calibration of the instrument: Regular maintenance and calibration of the dry Film Thickness Gauge to ensure the accuracy and stability of the measurement results.

When measuring, attention should be paid to the flatness, uniformity and cleanliness of the surface of the coating to be tested to avoid interference with the measurement results.

Pay attention to the measurement angle and position when measuring to ensure the accuracy and repeatability of the measurement results.

Select the appropriate measurement mode, such as single measurement, continuous measurement, etc., according to the actual application needs.

For different types of coatings and coatings, appropriate probes and measurement parameters should be selected to ensure the accuracy and reliability of measurement results.

After the measurement, the instrument should be cleaned in time and kept in a dry state to avoid damage to the instrument.

- 1Coating Thickness Gauge: How to measure the dry film thickness of non-metallic substrates?

- 2How to detect the thickness of dry film?

- 3Film Film thickness determination method

- 4Electroforming post-treatment - metal surface treatment

- 5A nondestructive measurement method of nonmagnetic coating thickness on magnetic metal substrate

姚广仁 - 《磁性金属基体上非磁性涂层厚度的无损检测方法》

- 6Determination method and step of coating thickness of dry film

- 7GB/T13452.2-2008 Determination of film thickness of Paints and varnishes [text version]

- 8Necessity and method of wet-film and powder thickness measurement and estimation of Dry-Film

- 9Film Film thickness determination