Ultraviolet aging Test Chamber, aging test principle, application, operation and selection problems

concept

What is UV aging?

UV aging refers to the aging process of materials caused by ultraviolet radiation. It usually occurs when materials are exposed to UV radiation, such as sunlight and artificial UV rays. UV radiation can cause chemical reactions in materials, such as oxidation, fracture and crosslinking, causing changes in the physical and chemical properties of materials. These changes can lead to changes in color of the material, embrittlement, weakening and degradation, etc.

In nature, many substances, such as wood, plastic, rubber, paper and textiles, will age due to exposure to ultraviolet light. In industry and daily life, many products, such as automotive exteriors, building materials, outdoor furniture and textiles, etc., need to undergo UV aging tests to ensure that they can be used in the environment for a long time without failure.

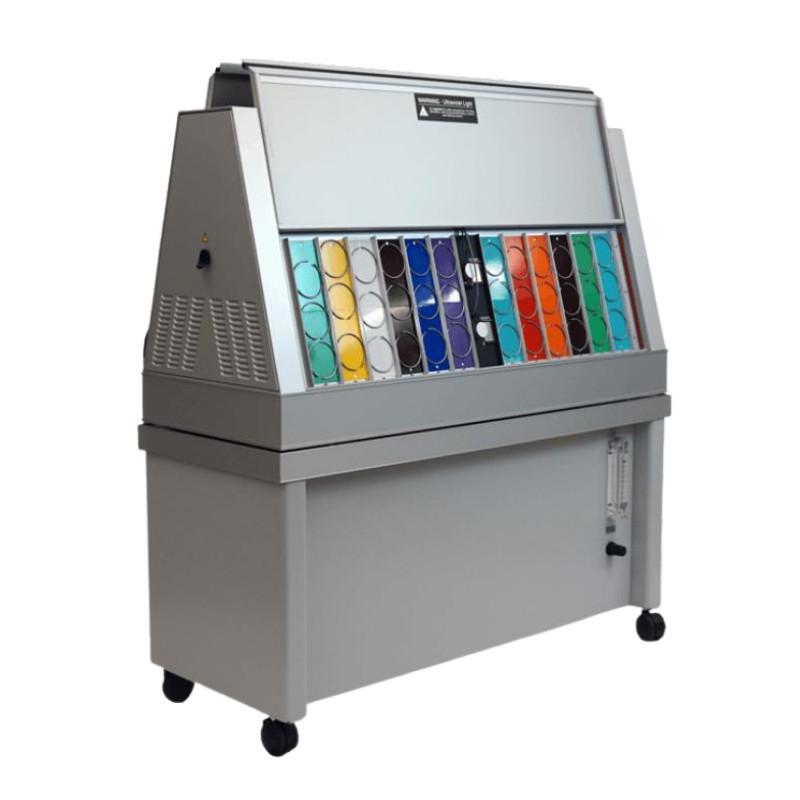

What is a UV aging Test Chamber?

The UV aging Test Chamber is an experimental equipment used to simulate the ultraviolet aging environment. It can simulate ultraviolet radiation under the sun, and conduct accelerated aging tests on materials by controlling parameters such as temperature, humidity, ultraviolet wavelength, irradiation intensity and irradiation time to evaluate the weather resistance and durability of materials.

working principle

The working principle of the UV aging Test Chamber is to simulate the ultraviolet radiation in the sun, and conduct accelerated aging tests on materials by controlling the wavelength, intensity, temperature, humidity and other parameters of the ultraviolet radiation.

Specifically, there are ultraviolet lamps inside the ultraviolet aging Test Chamber, and the ultraviolet spectrum produced by them is similar to the solar spectrum, which can simulate different wavelengths of ultraviolet radiation, such as UV-A, UV-B and UV-C. At the same time, the Test Chamber is also equipped with a temperature and humidity control system, which can control the temperature and humidity in the Test Chamber according to the test requirements. During the test, the material to be tested is placed in the test box, and after the test parameters are set, the aging test of ultraviolet radiation and constant temperature and humidity is carried out. The test time can generally be set from several hours to thousands of hours.

Through the test of the ultraviolet aging Test Chamber, the ultraviolet aging conditions in different environments can be simulated, and the rapid aging test can be carried out on the material to evaluate the durability and life of the material. Test results can guide product design and material selection, improve product quality and service life.

Application field

UV aging Test Chambers are used in many fields, some of the main applications include:

Material research and development: used to evaluate the durability and life of new materials, and guide the design and selection of materials.

Automotive industry: used to test the weather resistance of automotive exterior parts, such as body paint, tires, seals, etc.

建筑行业:用于测试建筑材料的耐久性,如涂层、地板、窗户、门等。

电子行业:用于测试电子产品外壳和配件的耐候性,如手机外壳、电视机外壳、电线、插头等。

医疗行业:用于测试医疗设备和器具的耐候性,如手术器械、医用塑料制品等。

化妆品行业:用于测试化妆品在紫外线辐射下的稳定性,如防晒霜、口红、指甲油等。

如何操作?

操作紫外光老化试验箱需要以下几个步骤:

准备样品:According to测试需要,准备好需要测试的材料样品,例如塑料、涂料、橡胶、纺织品等。

设置测试参数:According to测试需要,设置测试参数,包括紫外线辐射波长、辐照强度、温度、湿度和测试时间等。

将样品放置在试验箱内:将准备好的样品放置在试验箱内,并According to需要设置样品的布局和摆放方式。

开始测试:启动紫外光老化试验箱,开始进行测试。测试过程中需要定期监测试验箱内的温度、湿度和紫外线辐射强度,并记录测试数据。

完成测试:测试完成后,停止试验箱的运行,取出样品,进行测试结果的分析和评估。

在操作紫外光老化试验箱时,需要注意下面这几点:

样品的摆放和布局应该合理,避免相互遮挡,影响测试结果。

样品的放置应该注意避免接触试验箱内的金属部件,以免产生干扰影响测试结果。

在测试过程中需要定期清洁试验箱内部的紫外线灯管和反射板,进而保证测试精度。

在测试前,需要校准紫外线灯管的辐照强度和波长,以确保测试结果的准确性。

如何选型?

选择合适的紫外光老化试验箱需要考虑以下几个方面:

测试需求:首先需要确定测试的材料种类、测试参数以及测试标准等,以确定所需的紫外光老化试验箱的型号和规格。

可靠性和精度:需要选择品质可靠、精度高的紫外光老化试验箱,以确保测试结果的准确性和稳定性。

功能配置:需要According to测试需求选择合适的功能配置,例如紫外线灯管数量、温度控制方式、湿度控制方式、自动液位补充装置等。

品牌和服务:选择熟识品牌的紫外光老化试验箱,可以获得更好的品质保证和售后服务。

价格和性价比:需要According to自身的预算和需求,选择价格合适、性价比高的紫外光老化试验箱。

在选型之前,可以先了解不同品牌和型号的紫外光老化试验箱的性能、规格和价格等信息,并参考用户评价和推荐,以帮助选择合适的产品。同时,可以与厂家或供应商进行沟通和咨询,以了解更多有关产品性能和技术支持方面的信息。

常见问题

在使用紫外光老化试验箱的过程中,常见的问题有以下几个:

1、测试结果不准确:

可能是因为紫外光灯管老化或者未定期校准造成的,可以定期更换灯管和进行校准进而保证测试结果的准确性。

2、试验箱内温度不稳定:

可能是因为试验箱内部温度控制系统故障或者试验箱的密封性不好所导致的,可以检查温度控制系统和密封性,并及时维护保养。

3、试验箱内部积水:

可能是由于试验箱内部的自动液位补充装置故障或者排水管道堵塞所导致的,可以清洁排水管道或者更换自动液位补充装置以解决问题。

4、试验箱的使用寿命较短:

可能是由于质量问题或者使用不当所导致的,可以选择品质可靠、厂家售后服务好的产品,并注意正确使用和定期维护保养。

5、使用不当导致的安全问题:

需要注意试验箱的电源安全、紫外线辐射的危害、试验箱内的化学品储存和处理等问题,以确保使用安全。

In the process of using the UV aging Test Chamber, it is necessary to pay attention to normal use and regular maintenance, and to deal with and solve problems in time to ensure the accuracy and safety of the test.

UV aging Test Chambers are commonly used to test the aging characteristics of various materials, such as plastics, coatings, rubber, textiles, coatings, and cosmetics. Test results can help R&D personnel determine the reliability and life of materials, guide product design and material selection, and improve product quality and service life.

- 1Application and test of UV aging Test Chamber in silicon oxidation

- 2Application of UV aging Test Chamber in sunscreen clothing

- 3Application and test method of UV aging Test Chamber in Aluminum profile

- 4Application and related standards of ultraviolet aging test box in ceramics

- 5Application of xenon lamp photoaging Test Chamber in industrial protective coatings

- 6Ultraviolet aging Test Chamber selection skills

- 7Five test methods for evaluating coating durability

- 8Test method for yellowing resistance of polyurethane synthetic leather

王学川;周志军;张哲;强涛涛 - 《皮革与化工》

- 9Detailed Explanation of Laboratory Conditioning Test Technology for Polymer Materials

颜景莲 - 《电子世界》