The principle, application, operation and selection of wear-resistant testing and wear-resistant testing machines

concept

What is Abrasion Testing?

Abrasion testing is a common test method used to evaluate the abrasion resistance of a material, coating or surface. During this testing process, a specific device or instrument is usually used to simulate wear under actual conditions of use in order to determine the life, performance and quality of a material or surface.

Abrasion testing can be applied in various fields such as materials engineering, mechanical engineering, automotive engineering, construction engineering, electronics, etc. Commonly used wear test methods include: transverse friction test, reciprocating friction test, rotational friction test, etc.

Through wear-resistant testing, the wear-resistant performance of different materials or coatings can be evaluated, thereby optimizing product design and production, and improving product quality and life.

What is Abrasion Testing Machine?

Abrasion testing machine is a kind of testing equipment or instrument specially used for abrasion testing. It can perform wear resistance tests on various materials, coatings or surfaces to evaluate their wear resistance under actual use conditions.

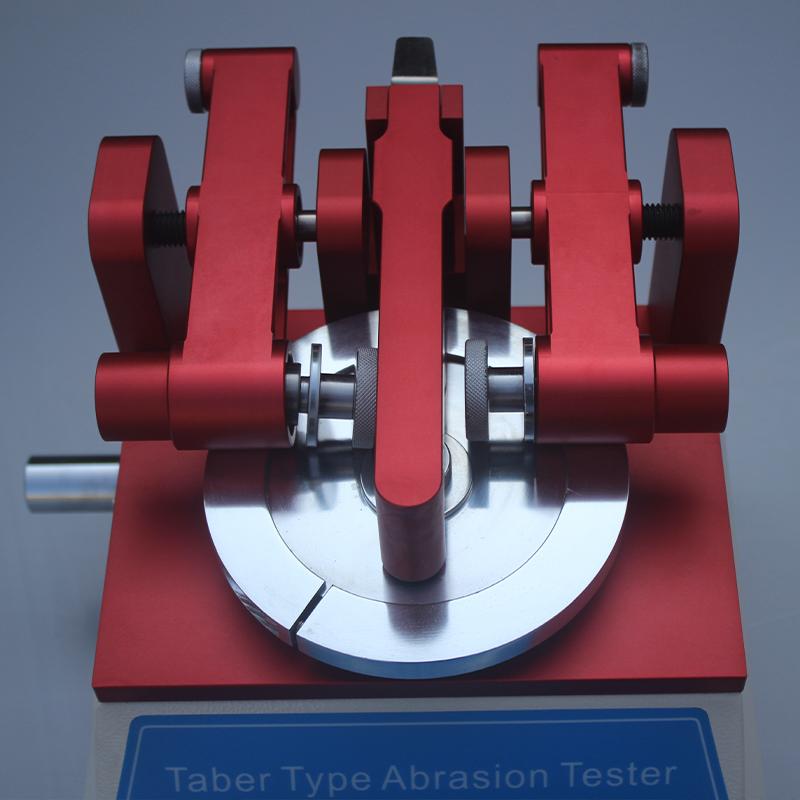

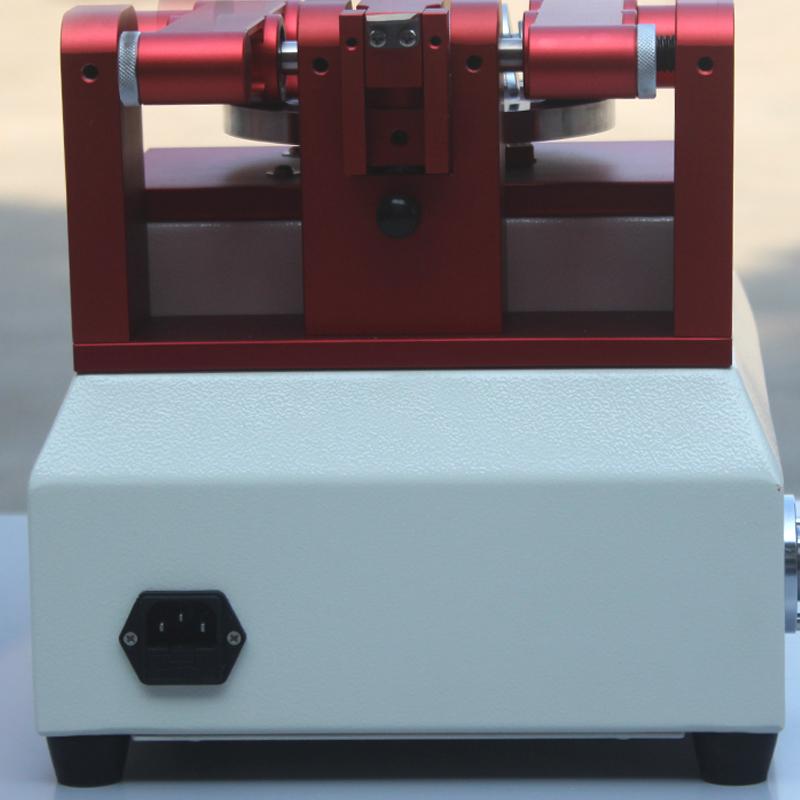

Abrasion testing machine is usually composed of test bench, sample clamping device, friction head, load system, motion control system, data acquisition system, etc. During the test, the sample is fixed on the test bench, and the friction head reciprocates or rotates on the surface of the sample through a predetermined load and speed, simulating the wear condition under actual use conditions, so as to measure the wear resistance of the sample.

Different types of wear Testers have different test parameters and test methods, such as: rubber wear Tester, wear fatigue Tester, grinding wheel wear Tester, roller wear Tester, etc. These testing machines can be widely used in materials engineering, mechanical engineering, automotive engineering, construction engineering, electronic products and other fields to evaluate the wear resistance of materials or products.

working principle

The working principle of the wear-resistant testing machine is to perform wear tests on the surface of the sample by simulating the wear process under actual use conditions to evaluate its wear resistance. The specific working principle is as follows:

Sample clamping and positioning: Fix the sample to be tested on the test bench, and clamp and position it correctly to ensure that the sample will not move or shake during the test.

Friction head load and motion: According to the test requirements, select the appropriate load and speed, and reciprocate or rotate the friction head on the surface of the sample through the predetermined load and speed.

Observation of the wear process: During the test, observe the change of the wear process through a microscope or video camera to understand the nature, rate and mode of wear.

Test data acquisition and processing: During the test, the test data is collected through load, displacement, time and other sensors, and the data is processed and analyzed by a computer or data acquisition system to obtain test results and curves.

Through these steps, the wear Tester can simulate various wear conditions to evaluate the wear resistance of materials or products. Test results can be used to guide product design and production, improve product quality and life.

Application field

Abrasion testing machine can be widely used in the following fields:

Material Engineering: It is used to test the wear resistance of different materials in order to select suitable materials and improve the quality and service life of materials.

Mechanical Engineering: It is used to test the wear resistance of various mechanical parts, transmission systems, bearings, etc., so as to select suitable parts and improve the reliability and durability of mechanical equipment.

Automotive engineering: used to test the wear resistance of auto parts, body coatings, tires, etc., in order to select suitable materials and coatings to improve the safety and life of the car.

Construction engineering: used to test the wear resistance of building materials, ground coatings, etc., in order to select suitable materials and improve the durability and aesthetics of buildings.

Electronic products: It is used to test the wear resistance of the surface coating of electronic products, keyboards, mice, etc., so as to select suitable materials and improve the reliability and service life of electronic products.

How to do it?

To operate an abrasion Tester, the following steps need to be followed:

Prepare samples: According to the test requirements, prepare the samples to be tested and ensure that the surface of the samples is clean, flat and free of obvious defects.

Mounting the sample: Mount the sample on the test bench and make sure the clamps are secure to avoid movement or falling off during the test.

Set test parameters: According to test requirements, set test parameters, including load, speed, test time, etc., and select test modes and methods.

Start test: Start the test program and start the test. During the test, the wear testing machine will automatically execute the test program and collect the test data.

Observe the test process: During the test, observe the wear changes on the surface of the sample to understand the wear resistance of the sample.

Stop the test: When the test time is over or the test requirements are met, the test program is stopped and the test data and results are recorded.

Data processing: Import the test data into the computer or data processing system, analyze and process the data, and obtain the test results and curves.

南北潮提醒您:操作耐磨试验机需要具备一定的专业知识和操作技能,对于不同的样品和测试要求,需要According to具体情况进行相应的调整和操作。另外,操作时安全问题不容忽视,遵守试验室安全规定,避免发生意外事故。

如何选型?

选型耐磨试验机需要考虑以下几个方面:

测试要求:首先需要According to测试要求确定测试对象,如测试材料、零部件、产品等,以及测试参数,如载荷、速度、测试时间等。不同的测试对象和要求可能需要不同的耐磨试验机类型和规格。

标准和规范:According to相关标准和规范,如ISO、ASTM、GB等,了解测试方法和要求,以便选择符合标准的耐磨试验机。同时需要注意不同标准和规范可能有不同的要求和限制。

精度和稳定性:考虑耐磨试验机的测试精度和稳定性,以确保测试数据准确可靠。通常需要选择具有高精度和稳定性的耐磨试验机。

功能和特性:According to不同的测试要求和应用场景,选择具有相应功能和特性的耐磨试验机,如不同的载荷范围、测试模式、控制系统、数据处理功能等。

品牌和服务:选择熟识品牌和有良好售后服务的耐磨试验机供应商,以确保设备的质量和售后支持。

成本和预算:According to预算和成本考虑选择适合的耐磨试验机,不过需要注意不能仅仅以价格为主要因素进行选择,而应考虑设备的性能和品质。

常见问题

以下是一些常见的耐磨试验机问题:

1、样品磨损过程中出现异常:

如样品偏移、脱落、磨损不均等现象。这可能与样品的安装、试验参数设置、试验方法等有关,需要检查和调整相关参数。

2、数据不准确或测试结果不一致:

可能与设备本身的精度、稳定性有关,或者与操作人员的技能和经验有关。需要进行设备校准和调试,并培训操作人员的技能和知识。

3、耐磨试验机出现故障或损坏:

This may be related to the quality, maintenance, etc. of the equipment. It is recommended to choose a high-quality wear-resistant testing machine and carry out regular maintenance and maintenance.

4. The sample does not meet the requirements or the test method is incorrect:

When selecting samples and testing methods, it is necessary to follow the relevant standards and specifications, and pay attention to the surface treatment and treatment of the samples.

5. Poor coordination between the wear-resistant testing machine and other equipment or systems:

Such as data transmission, control system, etc. It is necessary to select and cooperate according to actual needs and equipment characteristics.

Abrasion testing machines can be used in various fields to evaluate the wear resistance of materials or products, provide guidance for product design and production, and improve product quality and life.

- 1Introduction to common wear resistance test methods

- 2Principle, Application and Selection of Adhesive Tape Wear testing machine

- 3Briefly introduce the working principle, application and selection precautions of rubber Wear testing machine

- 4Basic Principle and Application Analysis of Asphalt Wear testing machine

- 5Basic Principle and Application of Lubricating Oil Wear Resistance Tester

- 6Demonstration of RCA wear-resistant tape machine

Air - 《南北潮》

- 7How to extend the service life of rubber?

- 8Briefly describe how different industries view product packaging

- 9DIN wear testing machine for rubber wear testing