Application of Coating Machine on Lithium Battery Coating Film

1. Concept

1. What is lithium battery coating

Lithium battery coating refers to the process of coating a protective coating on the surface of the positive and negative electrode materials of the battery through a coating process during the production of lithium-ion batteries. This coating is usually composed of a polymer material and some additives to improve the safety, stability and performance of the battery.

Lithium battery coating is a very important part in the production of lithium-ion batteries. It can effectively prevent the positive and negative materials of the battery from being in direct contact with the electrolyte, and avoid excessive heat and gas generated by the material due to electrochemical reactions, which will cause the battery to overheat, catch fire or The occurrence of dangerous situations such as explosions. In addition, the lithium battery coating can also improve the electrochemical performance of the battery, such as the cycle life of the battery, discharge capacity, charging speed, etc.

The film coating machine plays an important role in the lithium battery coating film. It can accurately and uniformly apply the coating to the surface of the positive and negative electrode materials of the battery, and control the coating thickness and coating speed to ensure the stability of the coating quality and performance . The application of coating machine in lithium battery coating makes the production process more effective, reliable and safe, and provides strong support for the production and development of lithium-ion batteries.

2. What is a coating machine?

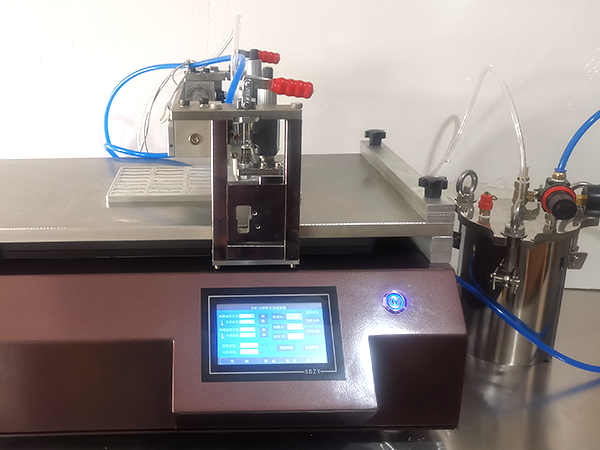

Coating machine is an instrument used to evenly coat coatings on flat materials. It can achieve an effective, accurate and repeatable coating process. It is widely used in various coatings, inks, glues, cosmetics, lithium battery coatings, etc. in the field.

A film coating machine usually consists of a flat plate, a coating template, a coating head, a coating speed controller and a coating thickness regulator. The user can select the appropriate coating template and coating parameters according to the coating requirements, such as coating speed, coating thickness, scraping head pressure, etc., and the coating machine will evenly coat the coating on the flat material according to the set parameters to obtain the desired coating effect.

The advantages of the film coating machine include effective, accurate, repeatable, saving paint and labor costs, etc., which can greatly improve the coating efficiency and coating quality. The application range of film coating machine is very wide, suitable for various materials and fields, such as electronics, automobile, construction, aerospace, chemical industry and so on.

Film coating machine is widely used in the fields of positive and negative electrode coating, diaphragm coating and battery casing coating in the lithium battery manufacturing process.

2. Application of coating machine on lithium battery coating

1. Positive and negative electrode coating

The coating machine can precisely control the thickness and uniformity of electrode coating to ensure the performance and consistency of the battery. When coating the positive electrode, a strip template is usually used to scrape the coating evenly on the conductive aluminum foil, and after drying and compression, a coating with uniform thickness and viscosity is formed; when coating the negative electrode, a roller template is usually used to uniformly coat the coating Coated on copper foil, dried and compressed to form a uniform coating.

2. Diaphragm coating

涂膜机可以实现隔膜的均匀涂布和厚度控制,保证隔膜的性能和一致性。在隔膜涂布时,通常使用条状模板,将涂料均匀刮在隔膜上,经过干燥后,形成均匀的涂层。

三、使用实例

以下是涂膜机在锂电涂膜中的一个操作流程:

准备工作:According to涂布对象和涂布涂料的要求选择合适的涂布模板和涂布参数,如涂布速度、涂布厚度、刮涂头压力等。对涂布器和模板进行清洗和校准,进而保证涂布的准确性和可重复性。

安装涂布模板:According to涂布对象的尺寸和形状选择合适的涂布模板,并将其安装到涂布机上。通常情况下,涂布模板会用夹具固定在涂布机上,进而保证涂布的精度和稳定性。

加入浆料:According to涂布模板的尺寸和涂布参数的要求,将浆料加入涂布机的涂料槽中,并保证浆料的质量和粘度符合要求。涂布机会According to设定的参数将涂料均匀地涂布到涂布模板上。

开始涂布:启动涂布机,调整涂布机的涂布参数,如涂布速度、涂布厚度、刮涂头压力等,进而保证涂布的精度和均匀度。将涂布对象放置在涂布模板下方,开启涂布机,涂布机会自动将涂料均匀地涂布到涂布对象上。

干燥和固化:在涂布完成后,将涂布对象移动到干燥室或者固化室中,进行干燥和固化。According to涂布涂料的要求和涂布参数的设置,确定干燥和固化的时间和温度,并保证涂布对象的温度和湿度符合要求。

检查和测试:在涂布对象干燥和固化后,对涂布质量进行检查和测试。According to涂布涂料的要求和涂布参数的设置,确定涂布质量的测试方法和标准,进而保证涂布质量符合要求。

When using a coating machine for lithium battery coating, it is necessary to select different coating templates and parameters according to the coating object and coating coating, such as coating speed, coating thickness, scraping head pressure, etc., to obtain better results. coating effect. At the same time, the applicator and template need to be cleaned and calibrated before coating to ensure the accuracy and repeatability of coating. The specific operation process of the film coating machine may vary due to different coating objects and coating materials, so it is necessary to understand the instruction manual of the coating machine in detail before operation, and make corresponding adjustments and operations according to the actual situation.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body