How to Prepare Graphene Slurry on Aluminum Foil with Film Coater

Graphene paste

Graphene slurry refers to a stable liquid suspension formed by dispersing graphene, a two-dimensional carbon material, in a solvent or other carrier, and generally contains a certain concentration of graphene. Since graphene is a material with extremely high specific surface area and special electronic structure, it is prone to aggregation and accumulation during the preparation process, which will lead to changes in the properties of graphene, so it is important to prepare high-quality graphene slurry Needless to say. Graphene slurry has a wide range of applications, such as the preparation of graphene films, conductive coatings, composite materials, biomedical materials, etc.

Significance of graphene slurry film making

Study the properties of graphene materials: preparing graphene films can provide samples that are easier to measure and analyze, because graphene films are more orderly and regular, and have better surface flatness and thickness consistency. This helps to study the physical and chemical properties of graphene, such as electrical, optical, magnetic and other properties.

Development of new graphene material applications: The preparation of graphene films in the laboratory can provide viable samples for the development of new graphene material applications. For example, preparing graphene transparent electrodes, preparing graphene nanobelts, quantum dots, etc.

Lay the foundation for subsequent processing and preparation: prepare graphene films in the laboratory to lay the foundation for subsequent processing and preparation. For example, the preparation of graphene films can be used as electrodes in electronic devices, and can also be used in the preparation of other nanomaterials.

Therefore, preparing graphene thin films is a common step in laboratory research, which is helpful for studying the properties of graphene materials and developing new applications. In the laboratory, a film coating machine can usually be used to prepare a graphene slurry film layer.

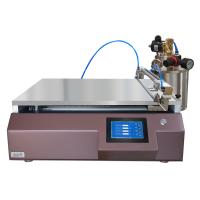

Coating machine

The coating machine is a laboratory equipment used to prepare thin film samples. It can quickly and accurately coat the coating or slurry on the surface of the substrate under certain conditions to form a film with a certain thickness and surface smoothness. film. Generally, a film coating machine is composed of a coating head, a coating speed adjustment device, a support, a controller and a power supply.

Steps of coating graphene on aluminum foil

The steps of coating graphene on aluminum foil using a coating machine are as follows:

Prepare aluminum foil and graphene coating: Cut the aluminum foil to be coated to an appropriate size and clean it. Prepare the graphene paint and dilute it to an appropriate concentration according to production requirements.

Adjust the parameters of the coating machine: According to the characteristics and requirements of the graphene coating, adjust the parameters of the coating machine, such as speed, coating thickness, etc.

Fix the aluminum foil on the Film Applicator: Use clamps to fix the aluminum foil on the table of the Film Applicator.

Load graphene paint: Inject the graphene paint into the coating head of the Film Applicator.

Start the film coating machine: start the film coating machine according to the operating instructions of the film coating machine, and start the film coating operation.

Control coating speed and thickness: By adjusting the parameters of the coating machine and the position of the coating head, the coating speed and thickness are controlled to ensure the stability of coating quality and performance.

Finished film application: When the film application is complete, turn off the Film Applicator and remove the aluminum foil.

Check the coating quality: check the thickness and uniformity of the coating, and carry out the necessary tests and analysis to ensure that the coating meets the production requirements.

The above are the basic steps of coating graphene on aluminum foil, and the specific operation can be adjusted according to the actual needs and the characteristics of the coating machine. The operation of the film coating machine requires certain professional knowledge and skills, and it is recommended to operate under the guidance of professionals.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body