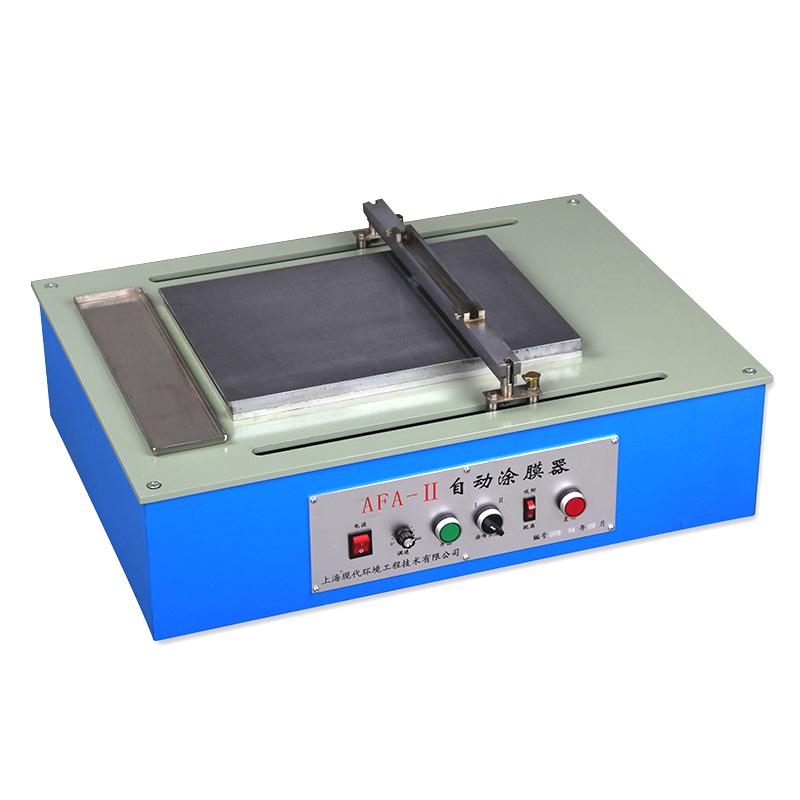

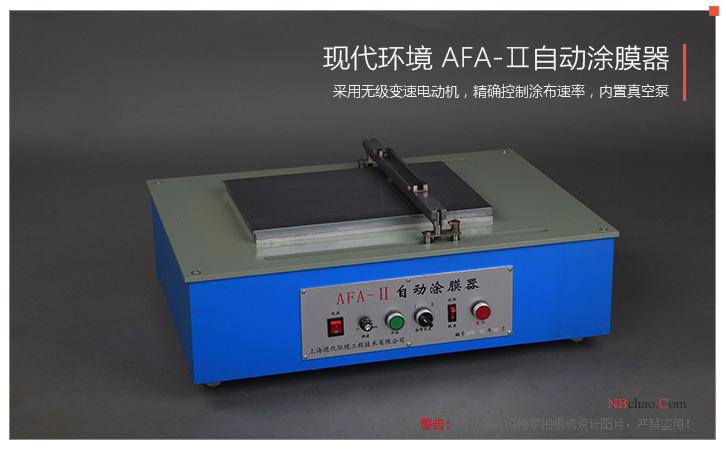

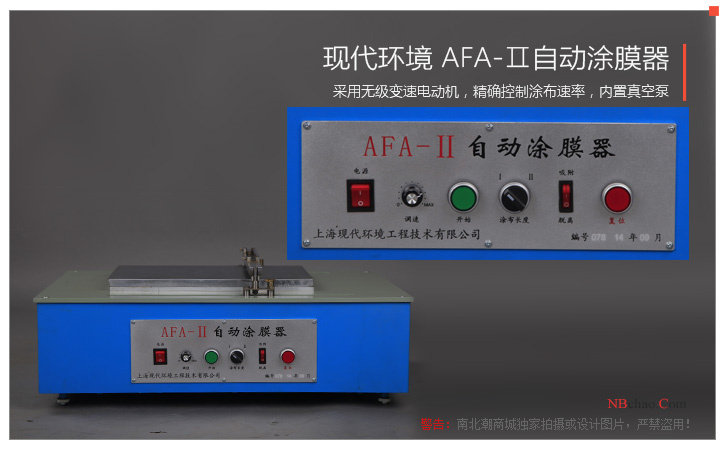

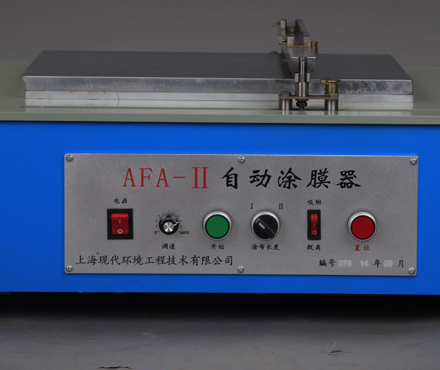

MODERNER AFA-II automatic Film Applicator

Moderner AFA-II Automatic Film ApplicatorSPEC

Moderner AFA-II Automatic Film ApplicatorDetails

Moderner AFA-II Automatic Film ApplicatorPacking list

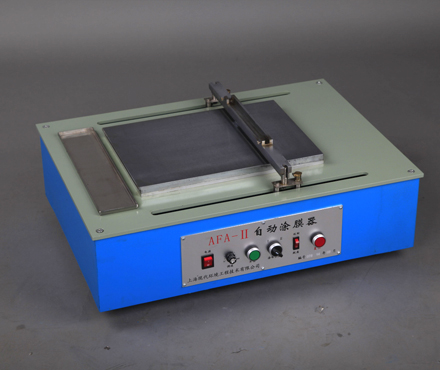

- SKU

- NB001018

- Coating method

- Wire rod/drawdown blade

- Coating size

- 400*280mm

- Application width

- 280mm

- Spreader trip

- 230mm/285mm

- Coating speed

- 0~100mm/s

- Total power consumption

- 350W

- Host Power

- 220V 50Hz

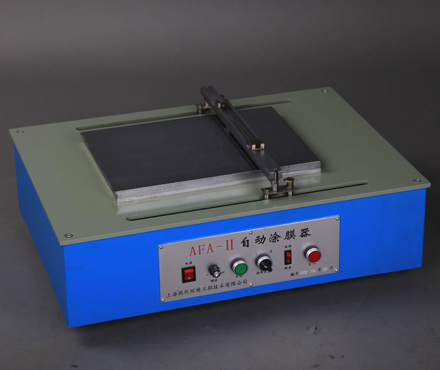

- Dimensions

- 705*505*270mm

- Machine Weight

- About 65Kg

- Vacuum Area

- 300*210mm

- speed control

- stepless speed regulation

Introduction

Low-cost manual coating is often affected by factors such as coating speed and uneven force. For high-precision and high-demand coating tests, it is obviously unable to meet the test requirements. MODERNER AFA-II automatic Film Applicator is an automatic coating machine carefully developed based on the problem of manual coating. It uses a continuously variable speed motor and a built-in Vacuum Pump. The vacuum size is 300mx210mm. There is no need for an external Vacuum Pump. It is easy to carry and carry, the coating film is uniform, the coating reproducibility is good, and it saves time and effort.

Actual pictures

Features

1) The AFA-II automatic Film Applicator uses a continuously variable speed motor to accurately control the coating rate.

2) The automatic Film Applicator uses a built-in Vacuum Pump and does not require an external Vacuum Pump, making it easy to carry and carry.

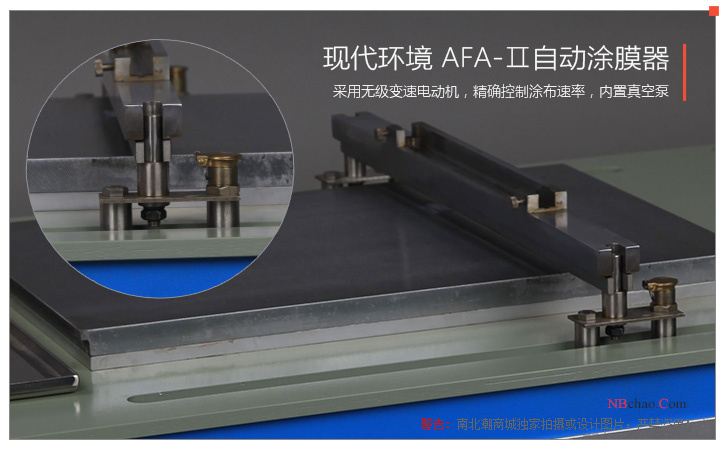

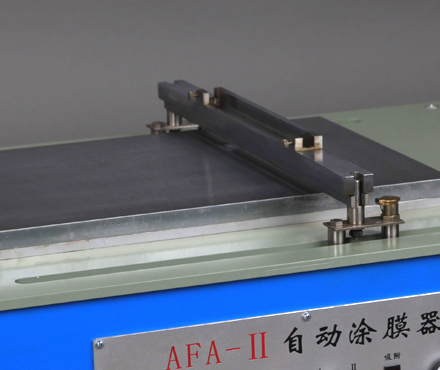

3) A horizontal bar is used to push the Wet Film Applicator, and there are no special requirements for the outer dimensions of the Wet Film Applicator.

4) There is a stainless steel waste collection tray on the left edge of the coating base, which can collect excess paint and ensure the cleanliness of the equipment's automatic Film Applicator and the surrounding environment.

Instructions

1) Turn on the power supply.

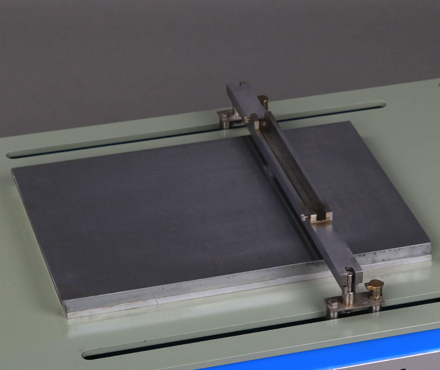

2) Place the substrate to be coated (such as hiding power paper) flatly on the coating base of the AFA-II automatic Film Applicator, turn on the Vacuum Pump switch to the "adsorption" position, and the coating substrate will be adsorbed to the coating at this moment on the base.

Note: When the size of the substrate to be coated is smaller than the vacuum-capable size, other paper or transparent tape should be used to cover the excess vacuum holes to prevent the substrate to be coated from being weakly adsorbed and causing coating failure.

3) Place the transverse push rod on the fixed rods on both sides of the coating base.

4) Select the appropriate coating length and press the "Reset" button to make the horizontal push rod reach the starting position of coating.

5) Place the Wet Film Applicator in front of the lateral pusher of the AFA-II automatic Film Applicator.

6) Choose the appropriate coating speed.

7) Place an appropriate amount of paint to be coated directly in front of the Wet Film Applicator.

8) Press the "Start" button and the Film Applicator starts coating.

9) After coating stops, scrape the remaining paint into the waste collection tray.

10) Turn off the Vacuum Pump and remove the prepared sample for the next operation.

Precautions for use

1) The coating base should be kept clean, and any debris stuck on it or paint that has accidentally fallen off should be cleaned up promptly to avoid affecting the flatness of the coating base.

2) Check the oil level in the oil cup regularly. If the oil level is found to be insufficient, add lubricating oil in time to lubricate the guide rail.

3) After each use of the AFA-II automatic Film Applicator , it should be covered with a dust cover to prevent dust from falling into the vacuum holes and being sucked into the Vacuum Pump, affecting its service life.

4) After each use of the AFA-II automatic Film Applicator , the waste collection tray should be cleaned in time.

AFA-II

AFA-II