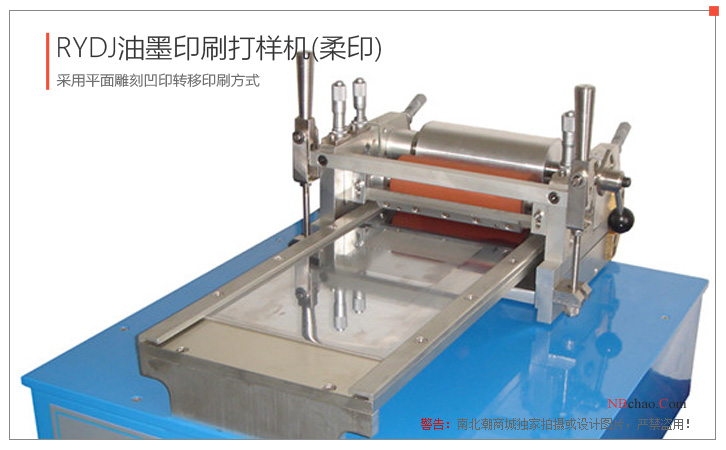

MODERNER RYDJ Ink Proofer (Flexographic Printing) Printability Tester

SEModerner RYDJ Proofer for flexographic ink printingSPEC

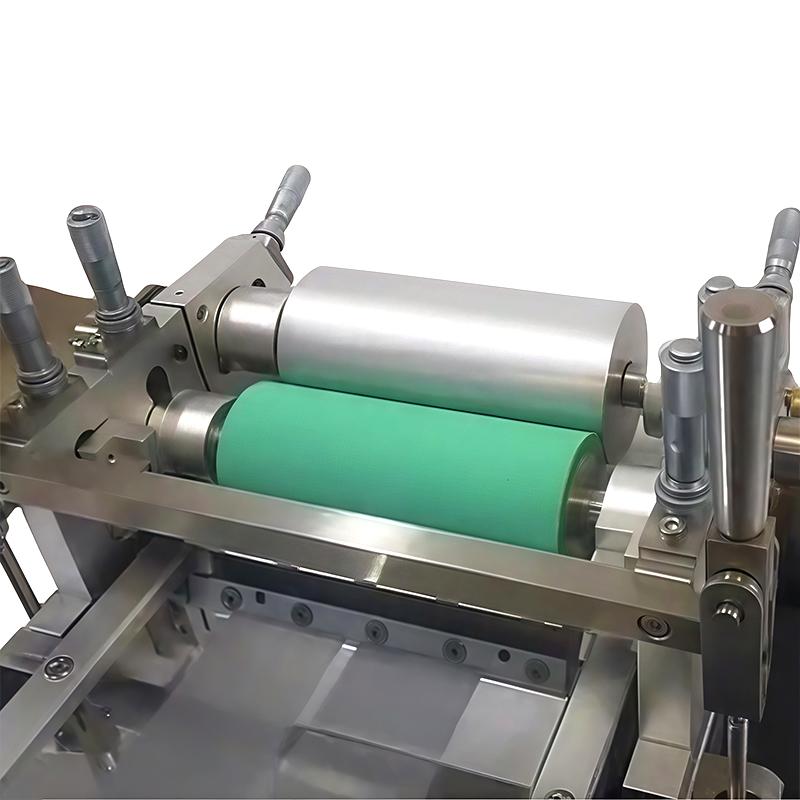

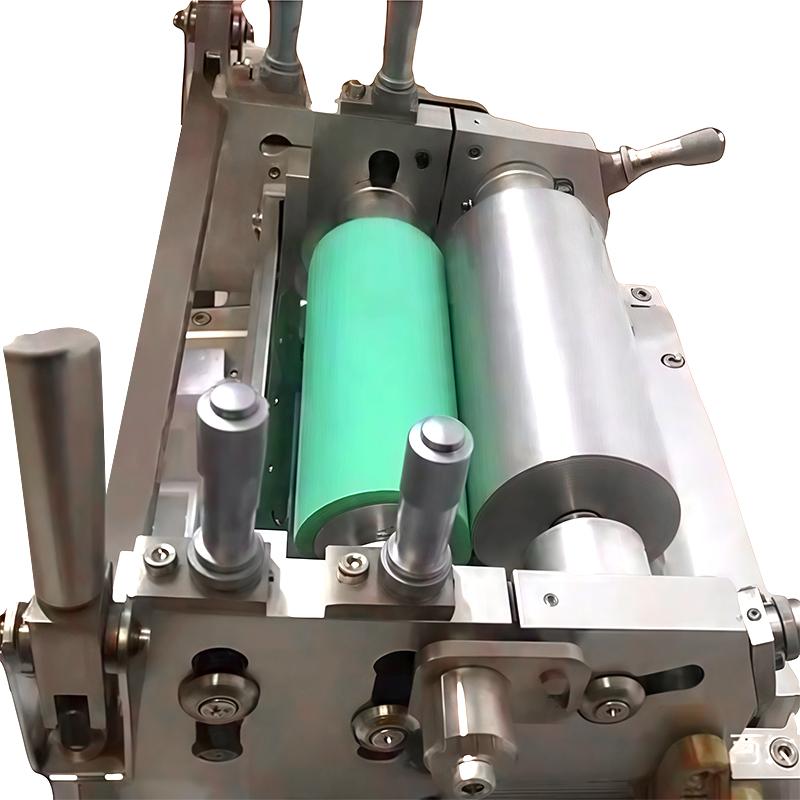

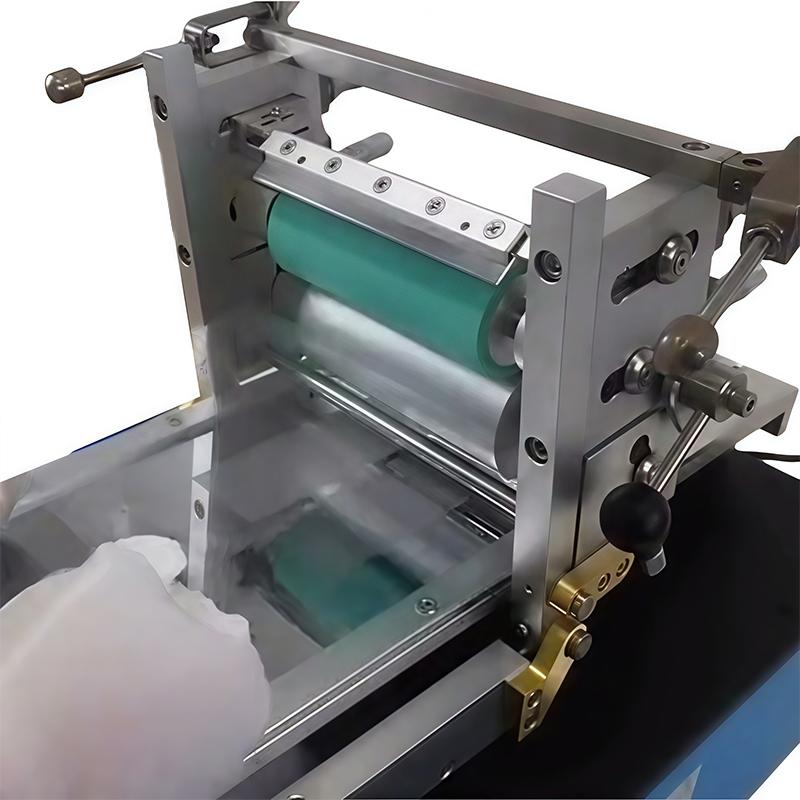

Moderner RYDJ Proofer for flexographic ink printingDetails

Moderner RYDJ Proofer for flexographic ink printingPacking list

- SKU

- NB001020

- Power

- 220V 50Hz

- Proofing speed

- 20/30/40/45M/min (four gears optional)

- Concave sample range

- 95×149mm

- Random gravure

- 150Lines/inch (available in A, B, C, D versions)

- Prooflet Specifications

- 120×240 mm

- Overall Dimensions

- 500*400*350mm

- Weight

- 27kg

Introduction

MODERNER RYDJ flexo ink printing proofing machine, that is, ink printing testing machine, is suitable for quickly producing flexo ink or water-based liquid ink printing proofs in the laboratory, which is convenient for the test of ink printing adaptability and the research and development of ink products. RYDJ flexo printing ink printing proofing machine adopts plane engraving gravure transfer printing method to work.

Applications

RYDJ flexo ink printing proofing machine is suitable for proofing flexible substrates such as paper, cardboard, and film.

Product operation process

1) Put the RYDJ flexo ink printing proofer on a stable and flat test bench, with the switch panel in front.

2) Install the gravure proofing plate first: place the printed side with specifications on the far end, align the non-printed side with the front end of the proofing plate installation table, and tighten the compression screws properly.

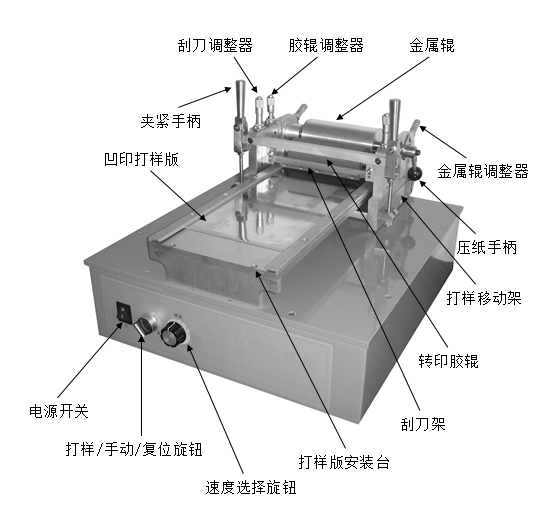

3) Loosen the clamping handle and lift up the proofing mobile frame. Install the squeegee on the scraper frame, and fasten the screw after leaning against the positioning pin. Tilt the scraper frame back about 45 degrees, and properly tighten the compression screw of the scraper frame. (Note: The squeegee is attached in the instruction manual packaging bag)

4) Push the proofing mobile frame back to the end. Loosen the locking ring at the bottom, and adjust the metal roller adjuster backward properly so that the metal roller does not contact the rubber roller. Also adjust the scraper adjuster and rubber roller adjuster upward properly, and confirm that the scraper and rubber roller will not contact the proofing plate when the proofing mobile frame is lowered and the clamping handle is locked.

5) Put down the proofing mobile frame of the RYDJ flexo ink printing proofing machine , and lock the clamping handle. First loosen the locking ring at the bottom, then adjust the rubber roller adjuster downwards, and finally lock the locking ring at the bottom, so that there will be a proper pressure between the rubber roller and the proofing plate, so as to ensure that the pressed film will not be pulled out easily That's it. Usually, at the beginning, touch the rubber roller parallel to the proofing plate, and then increase the scale of the spiral micrometer clockwise by about 1 to 2 turns, and make appropriate adjustments after trial printing depending on the leveling situation.

6) Loosen the locking ring at the bottom, adjust the scraper adjuster downward, lock and loosen the locking ring at the bottom, so that there is a suitable pressure between the scraping blade and the proofing plate, and the rest of the non-concave part can be scraped. ink. Usually, at the beginning, touch the ink scraper in parallel with the proofing plate, and then increase the scale of the spiral micrometer clockwise by about 1 to 2 circles. After the trial printing, make appropriate adjustments depending on the ink scraping situation.

7) Loosen the clamping handle and tighten the paper pressing handle. Loosen the locking ring at the bottom, adjust the metal roller adjuster forward, and then lock it after adjustment), so that there is an appropriate pressure between the metal roller and the rubber roller (it can’t be easily pulled out after pressing the sample sheet). Usually, at the beginning, touch the metal roller and the rubber roller in parallel, and then increase the scale of the spiral micrometer clockwise by about 1 to 2 circles. After the trial printing, make appropriate adjustments depending on the transfer situation.

8) Loosen the clamping handle and paper pressing handle, and confirm that the proofing mobile frame has moved back enough, and the "proofing/manual/reset" knob is in the "manual" position (middle position). Connect the power and turn on the power switch. First select the "1" gear speed (20 m/min), turn the "proofing/manual/reset" knob to the "proofing" gear, and confirm that the proofing mobile frame slides smoothly. After reset, select the appropriate proofing speed (usually you can choose "3" gear at the beginning, 40m/min), if the leveling is not satisfactory after trial printing, you can properly reduce the proofing speed.

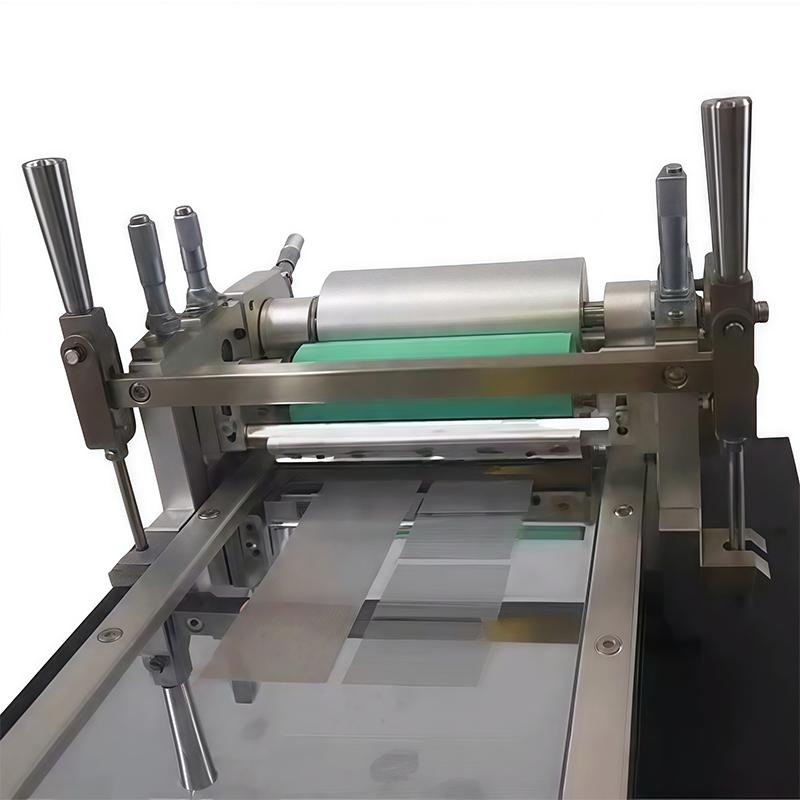

9) Proofing operation: Paste a flexible substrate sample of appropriate width and length (cardboard, film, etc., 120×240 mm size is recommended) on the metal roller with transparent tape (just paste the end that enters in the direction). Turn the paste end to the appropriate starting position (approximately near the connecting rod on the rear side of the proofing mobile frame), tighten the paper pressing handle, lock the clamping handle, and put an appropriate amount of ink on the proofing plate near the scraper (concave sample At the beginning, it is advisable to be close to the width of the concave sample and not exceed it). Turn the "proofing/manual/reset" knob of the RYDJ flexo ink printing and proofing machine to the "proofing" position, and the proofing moving frame quickly completes the proofing movement from back to front at the selected speed.

10) Loosen the clamping handle and paper pressing handle, and remove the sample. Lift the proofing mobile rack and select the "reset" file to make it back to the end (the reset speed has been adjusted before leaving the factory).

12) Use a soft cloth with an appropriate solvent or cleaning agent to quickly wipe off the residual ink on the scraper, proofing plate, rubber roller and metal roller, so as not to dry the ink for a long time and make it difficult to wash for the next proofing operation . During the scrubbing process, the "proofing/manual/reset" knob can be placed in the "manual" position (middle position), so that the proofing mobile frame can be moved back and forth at will, which is convenient for scrubbing operations. After scrubbing, reset the proofing mobile frame.

13) Observe the printing effect of the sample sheet, and make appropriate adjustments to the ink or RYDJ flexo ink printing proofer according to the proofing situation .

Pictures

Precautions for use

1) When using it for the first time, remove the protective paper (if any) on the proofing plate of the RYDJ flexo ink printing proofing machine .

2) When moving the proofing mobile frame forward with no load, be careful not to select the "45" gear (45 m/s) for proofing speed.

3) Lubricate the sliding guide rail at the lower part of the proofing plate mounting table in due course.

4) After each proofing is completed, the residual ink on the proofing plate and the rubber roller should be cleaned immediately and effectively to avoid "paste board".

5) Before proofing, confirm that there is no residue on the rubber roller and the concave part.

6) The proofing plate, squeegee, rubber roller and metal roller of RYDJ flexo printing ink proofing machine play a very important role in the proofing effect. Do not bump or scratch during use, and clean them in time after use.

7) If you want to manually move the proofing mobile rack during use, please set the "proofing/manual/reset" knob to the center. If the "proofing" file is selected, the proofing mobile frame will move forward rapidly at the selected speed. If the "reset" file is selected, the proofing mobile frame will fall backward at a preset speed.

Note: The return speed of RYDJ flexo ink printing proofing machine has been preset before leaving the factory, and usually does not need to be adjusted (it can be adjusted through the small opening at the bottom of the machine).

Product outline drawing

- 1GB/T 17001.2-2025《Anti-counterfeiting printing ink—Part 2:Magnetic anti-counterfeiting printing ink》

- 2GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 3TAPPI TIP 0304《Proofing of a Flexo Printing Ink》

- 4GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6GB/T 22365-2008《Paper and board - Determination of printing surface strength - Accelerating speed method》

- 7ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

RYDJ

RYDJ