Germany HTechMT SP100 Pointer Roughness Gauge

SE

HTechMT SP100 Roughness GaugeSPEC

HTechMT SP100 Roughness GaugeDetails

HTechMT SP100 Roughness GaugePacking list

- SKU

- NB010215

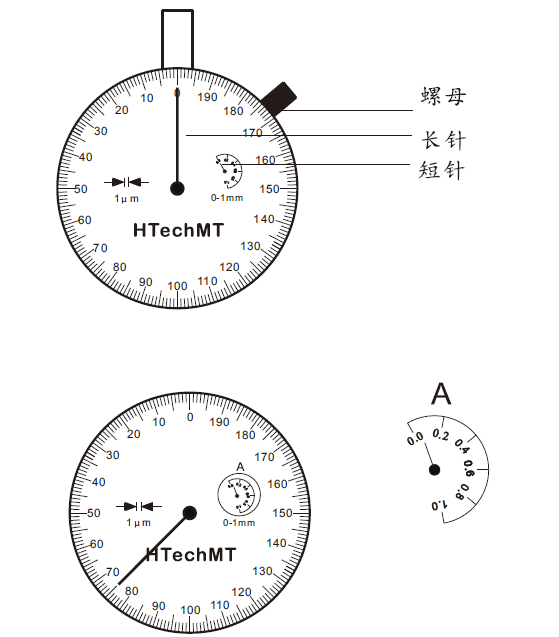

- Display mode

- Pointer

- Measurement parameters

- μm

- Measurement range

- 0~1000μm

- Resolution

- 1μm

- Dimensions

- 105*55*25mm

- Product Weight

- 400g

- Applicable standards

- ASTM D4417、SANS 5772

Introduction

Surface roughness meters are used to accurately measure the peak to surface roughness of sandblasted or shot blasted surfaces. The average value of a series of measurements is the surface roughness of the measured surface. Allows comparison of surfaces during spraying. In addition to roughness assessment of sandblasted or shot blasted surfaces, the instrument can also be used to measure the depth of pits caused by corrosion. The instrument has an accuracy of up to 1um. Implementation standards: ASTM D4417 and SANS 5772

Instructions

1. Place the surface roughness meter on the glass piece, press the base firmly, and adjust the reading of the meter to 0.

2. When reading data, place the instrument firmly on the surface of the object being measured. When measuring, do not drag the instrument on the surface under test. Doing so will cause the spring-supported measuring points to wear out, leading to data errors.

3. According to the description or opinions reached by the relevant parties, select enough points in each area that can represent the roughness of the measured surface for testing, and then select at least 10 points in the tested area for testing, and the average of the test values ââââof the 10 points The value is the surface roughness of that area.

- 1On surface roughness Measuring method Optical inspection, Mechanical, Atomic Force Microscope (AFM)

- 1JJF 1105-2018《Calibration Specification for Contact(Stylus)Instruments of Surface Roughness Measurement by Profile Method》

- 2JJG 2018-1989《Measuring Instruments for Surface Roughness》

- 3GB/T 28210-2024《Thermal-sensitive paper》

- 4HB 6172-1988《General surface roughness》

- 5GB/T 42671-2023《Test method for surface roughness of carbon materials》

- 6JJG (轻工) 52-2000《Verification Regulation of Roughness Tester for Paper and Board》

- 7QB/T 2693-2005《QB/T 2693-2005》

- 8GB/T 13288.2-2011《Preparation of steel substrates before application of paints and related products - Surface roughness characteristics of blast-cleaned substrates - Part 2: Method for the grading of surface profile of abrasive blast-cleaned steel - Comparator procedure》

- 9GB/T 6060.5-1988《Metal asperity comparison specimens, shot throwing (spraying), sand blasting machined surfaces (neq ISO 3632-II: 1985)》

SP100

SP100