CNSHP DC-2015 Digital Display Thermostatic Bath -20 ℃/15L

SEhengping DC2015 Thermostatic BathSPEC

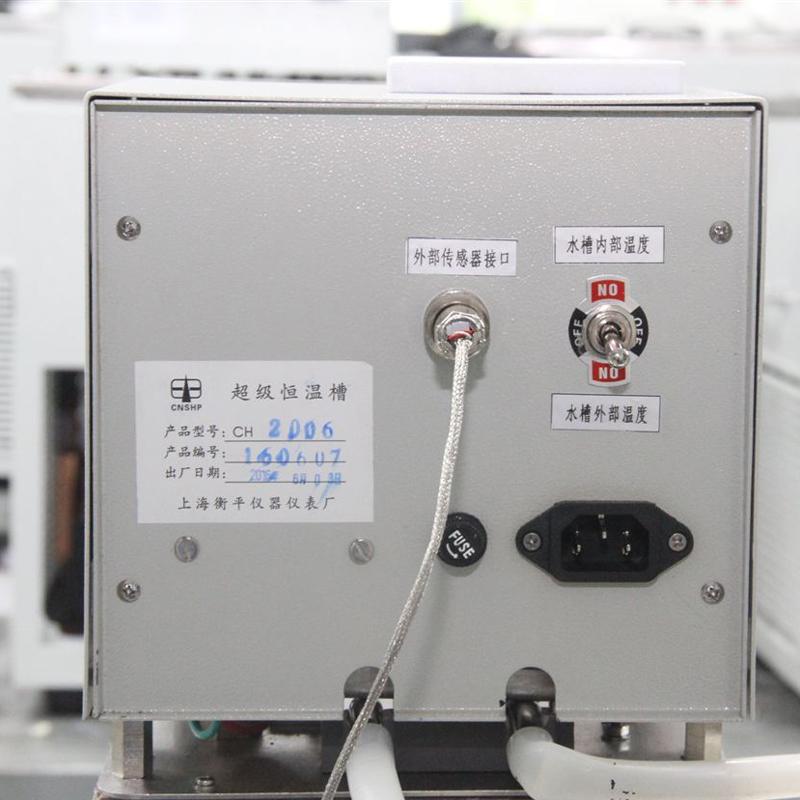

hengping DC2015 Thermostatic BathDetails

hengping DC2015 Thermostatic BathPacking list

- SKU

- NB010282

- Temperature range

- -20~100℃

- Temperature Fluctuation

- ±0.05℃

- Temperature Resolution

- 0.1℃

- Tank Volume

- 15L

- Tank opening Dimensions

- 215*175*200mm

- Temperature control mode

- Microcomputer temperature control, PID adjustment

- Circular mode

- Internal/external circulation

- Dimensions

- 375*455*740mm

- Flow rate of pump

- 10L/min

- refrigeration method

- Compressor refrigeration

The microcomputer temperature-controlled low-temperature constant temperature tank adopts single-chip micro-processing control, self-tuning PID adjustment, imported high-precision platinum resistance (Pt100) temperature measurement, high temperature control accuracy, and small fluctuations; the compressor with good fully enclosed technology (less than - The 40°C or 30L series adopts fully imported double compressor cascade refrigeration technology and heat exchange system), with high refrigeration efficiency and low noise. The instrument works stably and reliably, and is easy and safe to operate.

Humanized design: Foldable handles on both sides are convenient for carrying the instrument, 20L and above series and low-temperature constant temperature bath below -40℃ adopt heavy-duty self-locking casters for easy movement. The low-temperature constant temperature bath adopts a professional overall foaming process, which has good heat insulation performance and effectively reduces the loss of cooling capacity.

Professional circulation stirring design: ensure that the liquid in the tank is dispersed evenly and smoothly in the internal circulation, and the heat exchange is stable. The volume of the Low Temperature Circulating Bath above 20L is 10L/min, the flow rate of the stirring pump is 10L/min, the rest is 8L/min, the temperature fluctuation is ±0.05℃, and the display resolution is 0.1℃.

Suitable for internal/external temperature control applications: the sample can be directly placed in an open bath to keep the temperature constant, and it can also be connected externally to control the external measurement unit that needs constant temperature.

Features

Adopt microcomputer temperature control PID adjustment, self-tuning control technology, temperature control accuracy up to ± 0.05 ℃

Fully enclosed brand compressor refrigeration system, no CFC, fast cooling.

Temperature range: optional -50 ~ 100 ℃ (the medium can be pure water, ethylene glycol, alcohol, etc. according to the temperature range), and can also design and produce customized products according to the requirements of users

Capacity range: 6L, 10L, 15L, 20L, 30L, and customized products can also be designed and produced in full accordance with user requirements.

The shell of the fuselage adopts anti-aging electrostatic plastic spraying technology, and the stirring pump of the platform liner is all made of high-quality SUS304 stainless steel materials, with excellent workmanship;

The fine workmanship of the front panel and table top of the chassis, coupled with the unique humanized R rounded corner design structure, can prevent operators from being injured by edges and corners inadvertently.

Removable ventilation grille for easy cleaning of the cooling unit's condenser

Internal circulation function: Adopt a heatless centrifugal circulation pump to avoid the influence of the traditional water pump on the temperature field of the tank due to its own heat production.

External circulation function: the circulation pump can conduct external circulation of constant temperature liquid to establish a second temperature field.

Low temperature constant temperature bath safety protection device:

1) With power-off protection function

2) With upper and lower limit temperature setting function

3) Temperature runaway protection and alarm function

4) The heating device has low water level anti-dry and explosion-proof functions

5) Multiple protection functions for compressor overheating and overcurrent

6) There is a sensor open circuit display function;

Applications

DC series low-temperature constant temperature bath is widely used in bioengineering, medicine, food, chemical industry, metallurgy, chemical analysis, petroleum and other fields, providing users with a high-precision, controlled, and uniform temperature constant field source. Colleges, factories, laboratories, and quality inspection departments provide users with a liquid environment with controlled heat and cold and uniform temperature when they work, and directly conduct constant temperature tests or tests on test samples or produced products in the tank, which can be used for direct Heating or cooling, as a temperature source for auxiliary heating or cooling, such as temperature control for reactors, fully automatic synthesis instruments, extraction and condensation devices.

Application

Constant temperature field: sensor detection, constant temperature biochemical reaction, constant temperature material aging, etc.

Biochemical field: rotary evaporator, Abbe refractometer, viscometer, rheometer, polarimeter, atomic absorption, ICP-MS, ICP, nuclear magnetic resonance, CCD, biological fermentation tank, chemical reactor (synthesizer), etc.

Materials field: Electron microscope, X-ray diffraction, X-ray fluorescence, vacuum sputtering plating, vacuum coating machine, ICP etching, various semiconductor equipment, fatigue testing machine, chemical deposition system, atomic deposition system, etc.

Medical field: superconducting magnetic resonance, linear accelerator, CT, low magnetic field nuclear magnetic resonance, X-ray machine, microwave therapy machine, medical cold cap, cooling blanket, etc.

Physical and chemical fields: lasers, magnetic fields, various molecular pumps, diffusion pumps, ion pumps, and materials.

Series

| 6L series | DC-0506 | DC-1006 | DC-2006 | DC-3006 | DC-4006 | DC-6506 | DC-8006 | DC-0506W |

| temperature range | -5 ~ 100℃ | -10 ~ 100 ℃ | -20 ~ 100℃ | -30 ~ 100℃ | -40 ~ 100℃ | -65 ~ 100℃ | -80 ~ 100℃ | -5~100℃ |

| temperature fluctuation | ±0.02°C (25°C, medium is water or alcohol) | |||||||

| display resolution | 0.01°C | |||||||

| Liner size | 6L | |||||||

| Size of the opening | 150×150×150mm (length×width×depth) | or Φ 70mm | ||||||

| pump cycle | Internal and external circulation | |||||||

| pump flow | 8L/min | |||||||

| control method | Microcomputer temperature control, self-tuning PID adjustment | |||||||

| Temperature Sensor | Platinum resistance Pt100 | |||||||

| Cooling method | compressor | two stage compressor | compressor | |||||

| Operating Voltage | 220VAC±10% , 50Hz | |||||||

| Total power | 1.2kw | 2kw | 1.2kw | |||||

| Dimensions | 340 × 405 × 670mm | 510 × 510 × 1100mm | 430 × 400 × 400mm | |||||

| remark | Rectangular stainless steel liner, stainless steel platen, setting and measurement are displayed separately | |||||||

| 10L series | DC-0510 | DC-1010 | DC-2010 | DC-3010 | DC-4010 |

| temperature range | -5~100℃ | -10~100℃ | -20~100℃ | -30~100℃ | -40~100℃ |

| temperature fluctuation | ± 0.02°C | ||||

| Temperature control method | Microcomputer temperature control, PID adjustment | ||||

| display resolution | 0.01°C | ||||

| inner tank volume | 10L | ||||

| Size of the opening | 215×170×150mm (length×width×depth) | ||||

| pump cycle | inner/outer circulation | ||||

| pump flow | 8L/min | ||||

| Cooling method | compressor refrigeration | ||||

| Operating Voltage | 220VAC±10%, 50Hz | ||||

| power | 2kw | ||||

| Dimensions | 340×405×670mm | ||||

| Remark | Rectangular stainless steel liner, stainless steel platen, setting and measurement are displayed separately | ||||

| 15L series | DC-0515 | DC-1015 | DC-2015 | DC-3015 | DC-4015 | DC-6515 |

| temperature range | -5 ~100℃ | -10 ~100℃ | -20 ~100℃ | -30 ~100℃ | -40~100℃ | -65~100℃ |

| temperature fluctuation | ± 0.02°C | |||||

| Temperature control method | Microcomputer temperature control, PID adjustment | |||||

| display resolution | 0.01°C | |||||

| inner tank volume | 15L | |||||

| Size of the opening | 215×175×200mm (length×width×depth) | |||||

| pump cycle | inner/outer circulation | |||||

| pump flow | 10L/min | |||||

| Cooling method | compressor refrigeration | two stage compressor | ||||

| Dimensions | 375 × 455 × 740mm | 450 ×550×900mm | 650 ×520×1000mm | |||

| 20L series | DC-0520 | DC-1020 | DC-2020 | DC-3020 | DC-4020 |

| temperature range | -5 ~ 100℃ | -10 ~ 100℃ | -20 ~ 100℃ | -30~100℃ | -40~100℃ |

| temperature fluctuation | ± 0.02°C ( at 25 °C, the medium is water or alcohol) | ||||

| Temperature control method | Microcomputer temperature control, PID adjustment | ||||

| display resolution | 0.01°C | ||||

| inner tank volume | 20L | ||||

| Size of the opening | 190×230×250mm ( L×W×D ) | ||||

| pump cycle | Internal and external circulation | ||||

| pump flow | 10L/min | ||||

| control method | Microcomputer temperature control, PID adjustment | ||||

| Temperature Sensor | Pt100 | ||||

| Operating Voltage | 220v±10% 50Hz | ||||

| Cooling method | compressor refrigeration | ||||

| Total power | 3KW | ||||

| Dimensions | 510 × 510 × 1100mm | ||||

| 30L series | DC-0530 | DC-1030 | DC-2030 | DC-3030 | DC-4030 |

| temperature range | -5~ 100℃ | -10 ~ 100℃ | -20 ~ 100℃ | -30 ~ 100℃ | -40 ~ 100℃ |

| temperature fluctuation | ± 0.02°C | ||||

| Temperature control method | Microcomputer temperature control, PID adjustment | ||||

| display accuracy | 0.01°C | ||||

| inner tank volume | 30L | ||||

| Size of the opening | 270 × 220 × 270mm (length × width × depth) | ||||

| pump cycle | inner/outer circulation | ||||

| pump flow | 10L/min | ||||

| Cooling method | compressor refrigeration | ||||

| Operating Voltage | 220V ± 10% 50HZ (AC) | ||||

| power | 3KW | ||||

| Dimensions | 444 × 600 × 1100mm | ||||

optional features

1. An external PT100 temperature sensor is optional, which can detect and control the temperature of the external system during external circulation in real time.

2. Optional built-in 1~30-stage temperature control program can be used for automatic program temperature control and real-time display of the set temperature-time program running status.

3. Optional RS232 or RS485 communication interface, easy to connect to the host computer, with ModbusRTU communication protocol.

4. Optionally design and install a magnetic stirring system, which can directly stir the liquid sample in the beaker in the working chamber of the constant temperature bath without an external vertical mixer, reducing redundant operations.

5. The built-in cooling coil in the tank is optional to cool down and control the exothermic reaction of the system.

6. An optional height-adjustable immersion loading platform can easily adjust the liquid level of the immersed sample.

7. Low water level protection and alarm function

8. Horizontal shape can be selected, which has the characteristics of compact structure, lower center of gravity, and stability.

- 1JJF 2019-2022《Measurement Specification for Temperature Performance of Liquid Constant Temperature Testing Equipment》

- 2JJF 1030-2023《Measurement and Test Norm of Metrological Characteristics of Thermostatic Baths for Temperature Calibration》

- 3GB/T 26809-2011《Thermostatic baths and circulators - Refrigerated circulators》

- 4GB/T 32710.3-2016《Safety requirements for environmental testing and conditioning equipment—Part 3: Refrigerated baths》

- 5JJF 1030-2010《Measurement and Test Norm of Thermostatic Bath's Metrological Characteristics》

- 6GB/T 26808-2011《Thermostatic baths and circulators - Refrigerated baths》

- 7GB/T 18856.4-2008《Test methods for coal water slurry, Part 4: Determination of apparent viscosity》

- 8FZ/T 50010.3-2011《Pulp for viscose fibres, determination of viscosity》

- 9GB/T 5209-1985《Paints and varnishes--Determination of resistance to water--Water immersion method》

- 10GB 9278-2008《Temperature and Humidity of Coating Specimen State Adjustment and Test》

DC2015

DC2015