RDS wire coating bar, the main precision Spreader, 3/8 hot-selling model coating bar summary

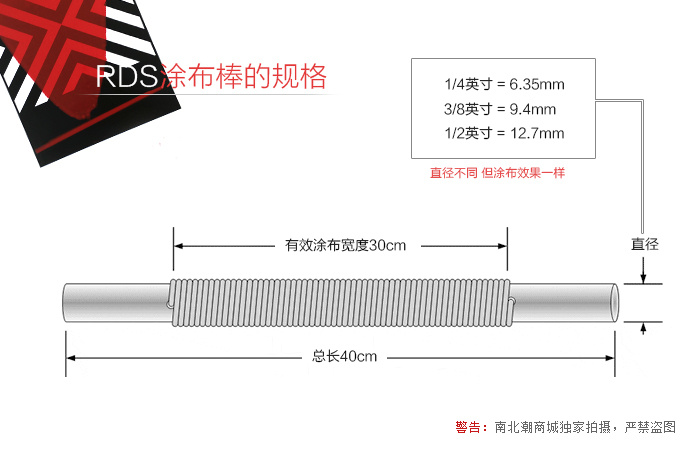

RDS SPEC

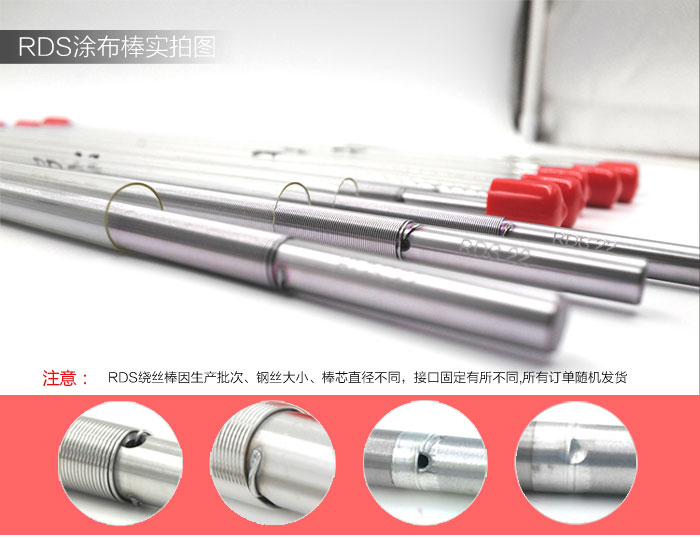

RDS Details

RDS Packing list

- SKU

- NB001032

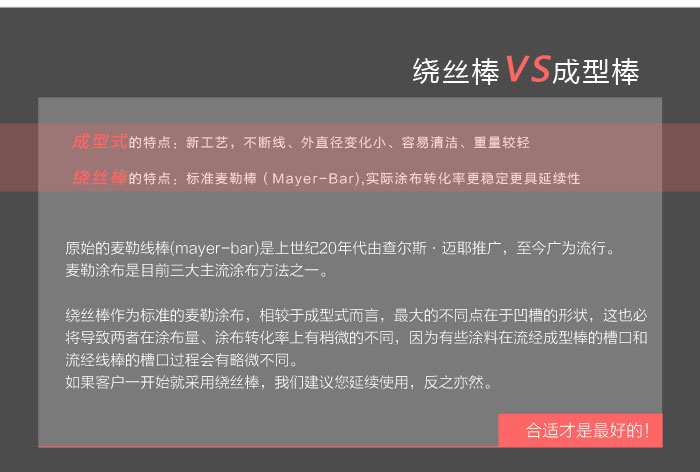

- Production process

- Wire-wound

- diameter

- 9.52mm

- Total length

- 400mm

- Application width

- 300mm

- grip width

- 50+50mm

- material

- stainless steel

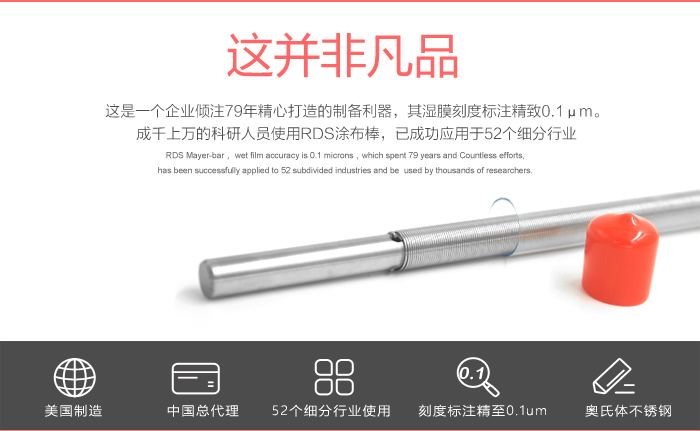

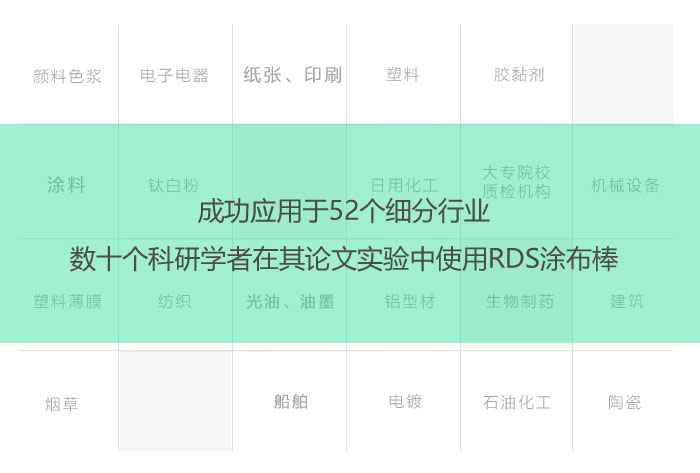

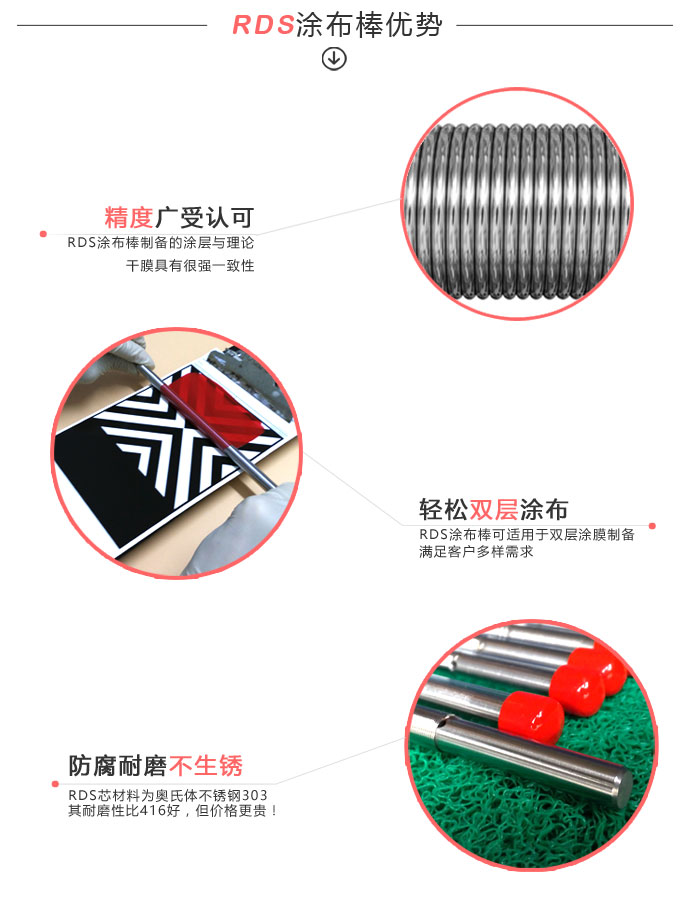

The Steel Wire Drawdown Rod produced by RDS adopts the Mayer-Bar principle, which controls the thickness of the wet film through the diameter of the steel wire, and is widely used in more than 50 subdivided industries in CHINA. Scraper rods are well used in coatings, inks, varnishes and various surface coating tests in the machinery manufacturing industry. In recent years, it has also been used as a common scraping instrument in **, biology, etc.

There are three main diameters of Steel Wire Drawdown Rods produced by RDS (including 1/4, 3/8/, 1/2 inches), and this product mainly aggregates the more mainstream 3/8 diameter Steel Wire Drawdown Rods in CHINA to facilitate users to place orders and purchases.

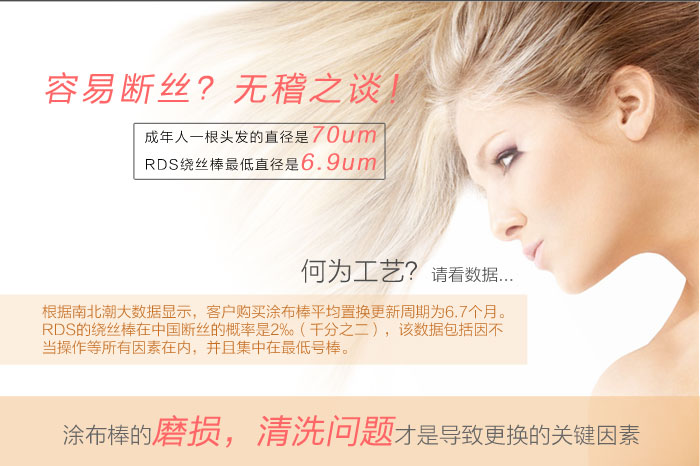

It is worth mentioning that some extrusion manufacturers advertise that the winding type is easy to break the wire, but this is actually a fallacy. Taking the coating rod sold in Nanbeichao Mall as an example, in the past 4 years, the breakage rate of RDS wire winding rod is 2‰ (2 thousandths), and it is concentrated in the lowest rod number. Moreover, the statistics include the improper use by the customer (including but not limited to bumps, deliberate, and the period of use far exceeds the period of industry users), because it is true that we cannot accurately determine what the customer is caused by far away. On the other side of big data, the replacement frequency of RDS scrapers in many industries in CHINA is 6.7 months (the data is obtained from the survey data in 2015), so whether the scraper is wound or extruded, it is actually the wear and tear that needs to be replaced. Just ask, a steel wire that can't even hit the diameter of a human hair, after thousands of times of wear, the accuracy must be problematic. However, some manufacturers generalize partially, and it is inevitable to mislead. Users are welcome to screen.