CNSHP CH2015 Thermostatic Bath 200 ℃/15L

SEhengping CH2015 Thermostatic BathSPEC

hengping CH2015 Thermostatic BathDetails

hengping CH2015 Thermostatic BathPacking list

- SKU

- NB010333

- Temperature range

- 15~200℃

- Temperature Fluctuation

- ±0.05℃

- Temperature Resolution

- 0.1℃

- Tank Volume

- 15L

- Tank opening Dimensions

- 218*170*200mm

- Temperature control mode

- Microcomputer temperature control, PID adjustment

- Circular mode

- Domestic circulation

- Total Power

- 1800W

- Dimensions

- 370*340*480mm

- Flow rate of pump

- 10L/min

Introduction

CH series microcomputer temperature-controlled super constant temperature bath adopts single-chip microprocessor control, self-tuning PID adjustment, imported platinum (Pt100) temperature measurement, high temperature control accuracy and small fluctuation; the instrument is stable and reliable, and the operation is convenient and safe. With burnout protection and over-temperature alarm function, the temperature fluctuation is up to ±0.05°C, the display resolution is up to 0.1°C, the pump flow rate is 10L/min, and the inner tank and box are made of high-quality stainless steel. Equipped with a Circulating Chiller, the constant temperature liquid in the tank can be drawn out to establish a second constant temperature field.

Application

Widely used in bioengineering, medicine, food, chemical industry, metallurgy, petroleum and other fields. To provide users with high-precision, controlled, and uniform temperature constant constant place, it is a research institute, colleges and universities. The factory laboratory, the quality inspection department's favorite constant temperature bath.

This series has various specifications, and customers can choose according to temperature range (100, 150, 200, 300 ℃) and inner tank volume (6, 15 liters). Whether you need internal or external circulation, you can choose from a wide range of high temperature baths for efficient heating. This series is wear-resistant and corrosion-resistant, and the application temperature is as high as 300°C.

Environmental requirements

The constant temperature bath should be placed on a solid workbench;

No vibration, no harmful gas;

The room temperature should be relatively stable, not fluctuating, otherwise it will affect the temperature control accuracy; the room temperature should be around 25°C,

The constant temperature tank should be maintained regularly, especially after working for a period of time, the cooling speed will slow down, the plastic mesh plate of the constant temperature tank should be removed, and the dust on the compressor and cooling plate should be removed.

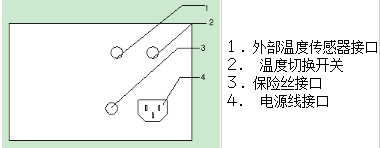

Instructions for optional thermostat internal/external temperature control function

The Water Tank has internal and external circulation functions (with an external lengthened PT100 temperature sensor), which can be used for constant temperature experiments in the tank, and can also be used to establish a closed second temperature field outside. When used as a second temperature field, the temperature of the second temperature field can be accurately measured and controlled by the internal and external temperature sensors behind the machine.

Instructions

When it is only necessary to do a constant temperature test in the Water Tank, turn the temperature switch to the internal temperature.

When it is necessary to establish a second temperature field for use, after connecting the external temperature sensor equipped with the machine to the machine, first turn the temperature switch to the internal temperature, set the temperature of the Water Tank to the required temperature, and wait for the meter to display a stable temperature of 10 After ~20 minutes, switch the temperature drop switch to the external temperature. At this time, the constant temperature tank can accurately control the temperature of the second temperature field through the internal PID temperature control instrument.

Note: Do not directly turn the temperature setting switch to the external temperature, so as to avoid accidents caused by excessive temperature in the constant temperature tank due to slow external temperature rise.

- 1JJF 2019-2022《Measurement Specification for Temperature Performance of Liquid Constant Temperature Testing Equipment》

- 2JJF 1030-2023《Measurement and Test Norm of Metrological Characteristics of Thermostatic Baths for Temperature Calibration》

- 3JG/T 25-2017《Test method for temperature change resistance of architectural coatings》

- 4GB/T 28853-2012《Thermostatic baths and circulators - Heated circulators》

- 5GB/T 32710.5-2016《Safety requirements for environmental testing and conditioning equipment—Part 5: Heating baths》

- 6JJF 1030-2010《Measurement and Test Norm of Thermostatic Bath's Metrological Characteristics》

- 7GB/T 26808-2011《Thermostatic baths and circulators - Refrigerated baths》

- 8GB/T 18856.4-2008《Test methods for coal water slurry, Part 4: Determination of apparent viscosity》

- 9HG/T 3323-1982《Rubber viscosity determination method (rotational viscometer method)》

- 10GB 9278-2008《Temperature and Humidity of Coating Specimen State Adjustment and Test》

CH2015

CH2015