INGERSOLL RAND v22-8 Air Compressor Displacement 3500L/min Motor Power 22KW

Ingersoll Rand v22-8 Air CompressorSPEC

Ingersoll Rand v22-8 Air CompressorDetails

Ingersoll Rand v22-8 Air CompressorPacking list

- SKU

- NB010414

- type

- fuel injection

- compression method

- screw type

- exhaust pressure

- 800kpa

- Displacement

- 3500L/min

- output power

- 22KW

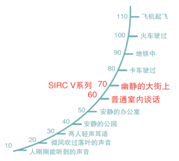

- noise value

- 66±3dB(A)

- Dimension

- 1295*870*1125mm

- Weight

- 640Kg

Innovative modular design, high integration and high reliability

| Host driver module — Durable Ingersoll Rand main engine: effective and stable, its performance has been verified and recognized by millions of Air Compressor customers equipped with modified main engine in Chinese market — Precise transmission system: A single Poly-V wide belt is used for transmission, which is more stress-dispersed and more stable than multiple thin belts — Effective motor: Class F insulation, Class B temperature rise, protection level up to IP55, effectively prevent dust and moisture from entering the motor, prolong the service life of the motor |

|

Cooling module — Integrated cooling module, designed cooling fan with specially designed air deflector, effectively reducing the noise of the unit and improving the operating efficiency of the unit — The unit uses centrifugal fans |

|

Control module — The design of the hot and cold chamber structure places the independent control module in the cold chamber to avoid premature aging of electrical components caused by high temperatures — Compact design saves more space in the unit |

|

Oil filtration and separation module — 15% fewer connection points than similar products, greatly reducing the incidence of leakage — Greatly reduce the oil content of the air, and can reach the industry professional level below 3ppm — Sealed with "O" rings, which radically improves the level of leakage resistance |

Silent design

| — Centrifugal cooling fan and integral cooling module are used to avoid errors when adjusting the coaxiality and clearance, and at the same time effectively reduce noise and vibration and improve cooling efficiency — Adopt closed silent box design, the inner side of the box is all pasted with sound-absorbing materials, which can effectively absorb noise, which is 3-5dB (A) lower than that of general Air Compressors. |

Humanized intelligent control system

| — User-friendly operation interface: the panel 450 is designed obliquely upward, LCD is displayed in Chinese and English, the interface is friendly and intuitive, and the parameters of the unit can be adjusted quickly and conveniently — Powerful comprehensive protection function: prevent damage caused by short circuit, stalled rotor, phase loss, overload, unbalance, etc. as much as possible, anti-reversal protection, and detection and control of temperature — Very good communication and joint control function: remote/local control selection, joint control operation selection, RS-485 communication function, remote monitoring with SMS function can be selected |

Independent system of hot and cold chambers and unique air duct design

| — Unique independent system design of cold and hot chambers, the internal layout of the unit is more reasonable — Placing electrical components and oil separation and filtration modules, which are susceptible to damage from high temperatures, in a cold chamber increases the service life of the unit — Professional air duct design keeps the compressor inlet air temperature and internal temperature relatively low: provide a separate cold air inlet channel for the Air Compressor intake to improve stability and efficiency, provide a separate air intake channel for the cooling of the motor and electrical components, ensure reliability, top exhaust air, easy for users to install a hot exhaust air system and heat recovery system |

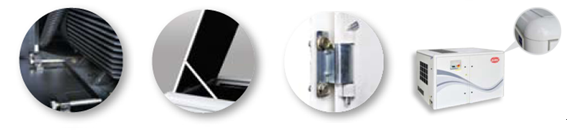

User-friendly design, fast self-service

— Easy to adjust the structure of the motor and main engine, simplifying the structure and increasing the operability

— Good motor design satisfies the ability to add grease without stopping the machine

— Large maintenance space and reasonable arrangement of spare parts

— Independent roof support structure, effectively reducing downtime and improving productivity

— Special hinged detachable door panel design for easy maintenance and maintenance

— All corners are rounded for stronger and safer

Air Compressor performance parameters

Models | pressure | Motor power | Exhaust volume | noises | Dimensions(mm) | weight | ||

barg | kW | m3/min | dB(A) | long | wide | high | Kg | |

V15-7 | 7 | 15 | 2.5 | 66±3 | 1295 | 870 | 1125 | 580 |

V15-8 | 8 | 15 | 2.4 | 66±3 | 1295 | 870 | 1125 | 580 |

V15-10 | 10 | 15 | 2.1 | 66±3 | 1295 | 870 | 1125 | 580 |

V15-12 | 12 | 15 | 1.7 | 66±3 | 1295 | 870 | 1125 | 580 |

V18-7 | 7 | 18.5 | 3.1 | 66±3 | 1295 | 870 | 1125 | 625 |

V18-8 | 8 | 18.5 | 3.0 | 66±3 | 1295 | 870 | 1125 | 625 |

V18-10 | 10 | 18.5 | 2.6 | 66±3 | 1295 | 870 | 1125 | 625 |

V18-12 | 12 | 18.5 | 2.2 | 66±3 | 1295 | 870 | 1125 | 625 |

V22-7 | 7 | 22 | 3.7 | 66±3 | 1295 | 870 | 1125 | 640 |

V22-8 | 8 | 22 | 3.5 | 66±3 | 1295 | 870 | 1125 | 640 |

V22-10 | 10 | 22 | 3.1 | 66±3 | 1295 | 870 | 1125 | 640 |

V22-12 | 12 | 22 | 2.5 | 66±3 | 1295 | 870 | 1125 | 640 |

V30-7 | 7 | 30 | 5.5 | 68±3 | 1654 | 1277 | 1232 | 982 |

V30-8 V30-10 | 8 10 | 30 30 | 5.2 4.8 | 68±3 68±3 | 1654 1654 | 1277 1277 | 1232 1232 | 982 982 |

V30-12 | 12 | 30 | 4.2 | 68±3 | 1654 | 1277 | 1232 | 982 |

V37-7 | 7 | 37 | 6.2 | 68±3 | 1654 | 1277 | 1232 | 1040 |

V37-8 | 8 | 37 | 6.0 | 68±3 | 1654 | 1277 | 1232 | 1040 |

V37-10 | 10 | 37 | 5.7 | 68±3 | 1654 | 1277 | 1232 | 1040 |

V37-12 | 12 | 37 | 5.0 | 68±3 | 1654 | 1277 | 1232 | 1040 |

Tested in accordance with PNEUROP/CAGI test standards

Tested in accordance with ISO 2151:2004 annex C test standard

Inlet air temperature collection point: the outside of the unit housing

Exhaust volume collection point: the exhaust point outside the unit shell

Exhaust pressure collection point: the exhaust point outside the unit housing